Telescopic chassis

A telescopic, chassis technology, applied in the direction of tracked vehicles, motor vehicles, transportation and packaging, can solve the problems affecting the performance of construction machinery, and achieve the effects of low production cost, improved performance, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

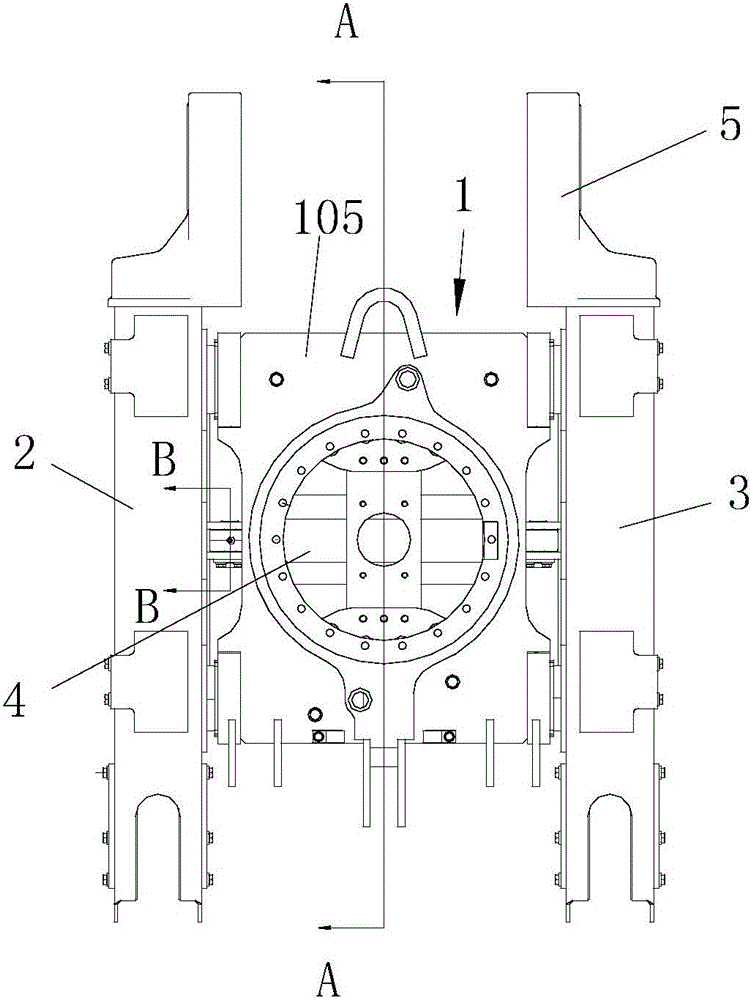

[0045] like figure 1 As shown, the retractable chassis includes a middle chassis 1, and the left and right sides of the middle chassis 1 are respectively provided with a left crawler beam 2 and a right crawler beam 3 with the same structure and mutual symmetry, and a Telescopic oil cylinder 4, telescopic oil cylinder 4 is a double-rod oil cylinder, and two telescopic rods of telescopic oil cylinder 4 link to each other with left and right crawler beams respectively.

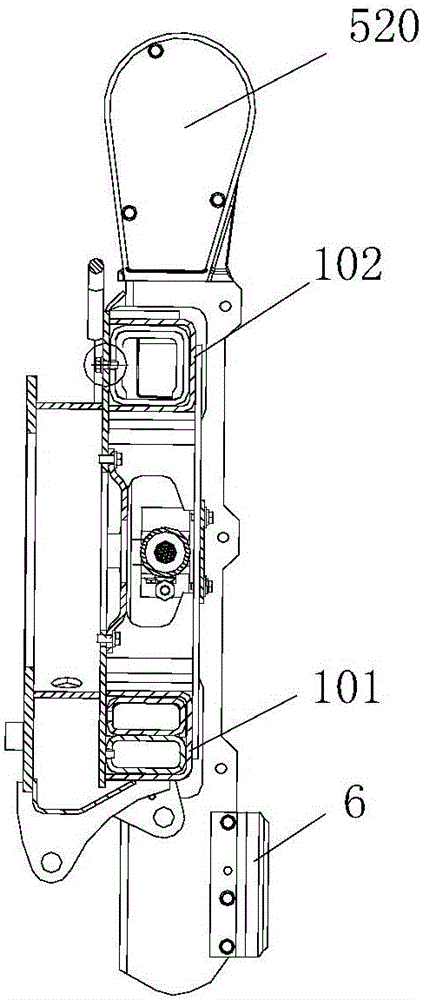

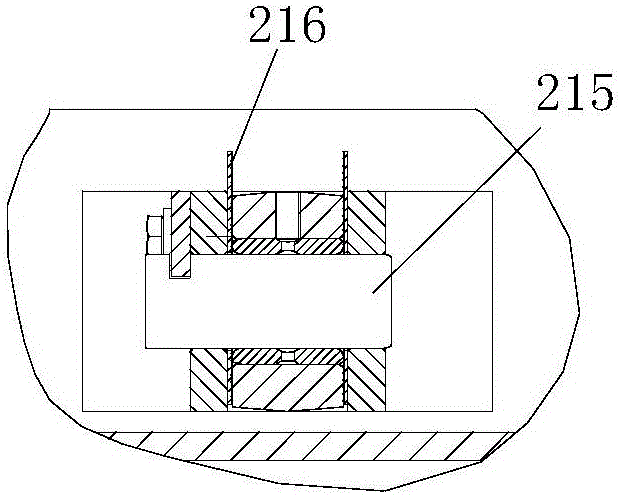

[0046] like Figure 8 to Figure 12 As shown, the rear portions of the left and right crawler beams are respectively provided with travel motor mounts 5, and each travel motor mount 5 includes a motor mount plate 51, a ring plate 52 surrounding the motor mount plate 51, and a ring The front plate 54 fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com