Accommodation ladder stretching-out system

A technology of gangway and ship's side, which is applied to ships, cargo handling equipment, passenger handling equipment, etc., can solve the problems of ignoring the distance change of gangway horizontal movement, high energy consumption cost, only considering the overturning of the gangway ladder, etc. The effect of reducing energy consumption cost and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

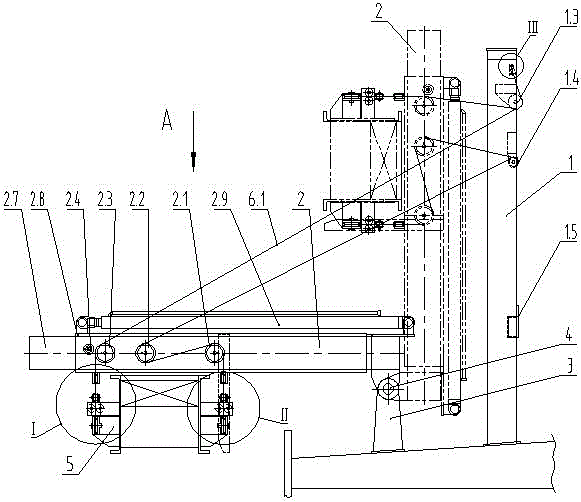

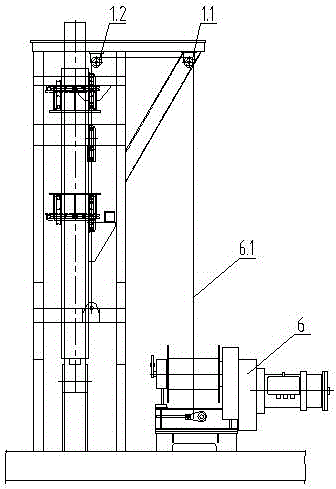

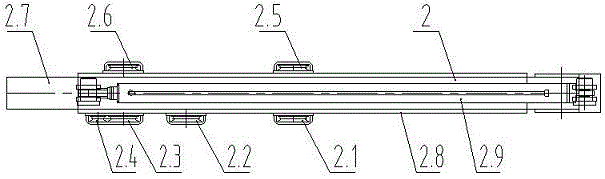

[0019] The outrigger system of the gangway shown in the accompanying drawings includes a column 1, a turning arm 2, an eye plate 3, a pin shaft 4, a gangway fixing device 5, and a driving winch 6; the column 1 is a steel frame structure, and is welded and fixed on the upper surface of the ship's side deck. Column pulley Ⅰ1.1, column pulley Ⅱ1.2 are arranged horizontally on the upper beam of column 1, and column pulley Ⅲ1.3 and column pulley Ⅳ1.4 are vertically arranged below column pulley Ⅱ1.2; eye plate 3 is fixed on the front end of column 1 On the side deck of the ship, the eye plate 3 is hinged with the turning arm 2 through the pin shaft 4; the front side of the turning arm 2 is provided with the turning arm pulley I2. Ⅱ2.2 and turning arm pulley Ⅲ2.3, the rear side is provided with turning arm pulley Ⅳ2.5 and turning arm pulley Ⅴ2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com