Multi-rotor aircraft body made of composite material and preparation method

A technology of multi-rotor aircraft and composite materials, which is applied in the field of composite material multi-rotor aircraft body and preparation, can solve problems such as blade damage, unfavorable normal operation, and affecting the flight effect of multi-rotor aircraft, so as to increase structural rigidity, increase resistance Crash ability, effect of improving effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

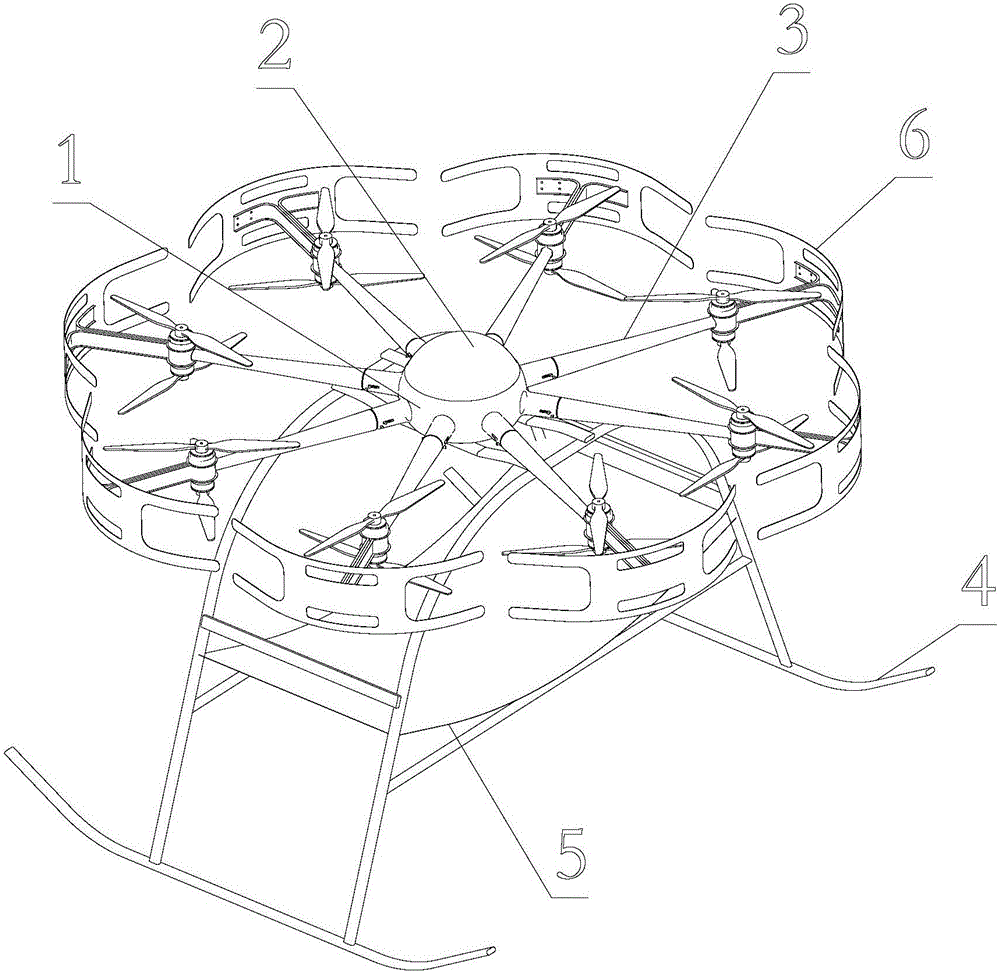

[0031] A composite material multi-rotor aircraft body, including an equipment cabin, a cantilever, a landing gear, a rotor, an anti-collision ring and a suspension; wherein, the equipment cabin is located inside, the anti-collision ring is located on the outside, and the equipment cabin and the anti-collision ring are connected by a cantilever, Eight sets of anti-collision rings are distributed on the outside of the cantilever, and a motor installation platform is provided on the cantilever, and the motor installation platform is equipped with a motor and a rotor; the landing gear is fixed at the bottom of the equipment cabin, and the suspension is connected to the landing gear and the equipment cabin.

[0032] The equipment compartment is an upper and lower split structure, which is divided into two parts: the equipment compartment and the equipment compartment cover. One side of the equipment compartment and the equipment compartment cover is connected by a hinge, and the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com