Heat shrinkable film packaging machine

A heat-shrinkable film and packaging machine technology, which is applied in the direction of packaging, wrapping paper, and wrapping paper shrinkage, can solve the problems of low processing efficiency of heat-shrinkable film packaging machines, high cost of process packaging materials, and moisture in labels and cartons. Reasonable, meet production needs, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

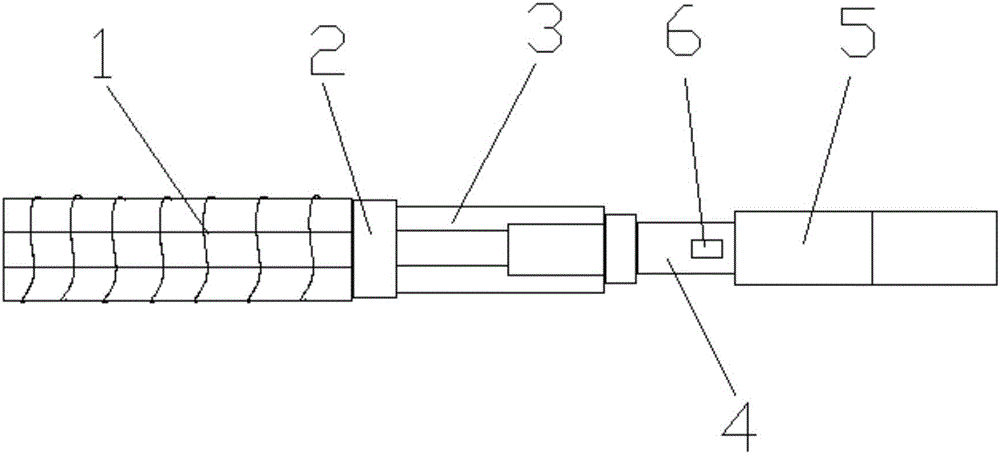

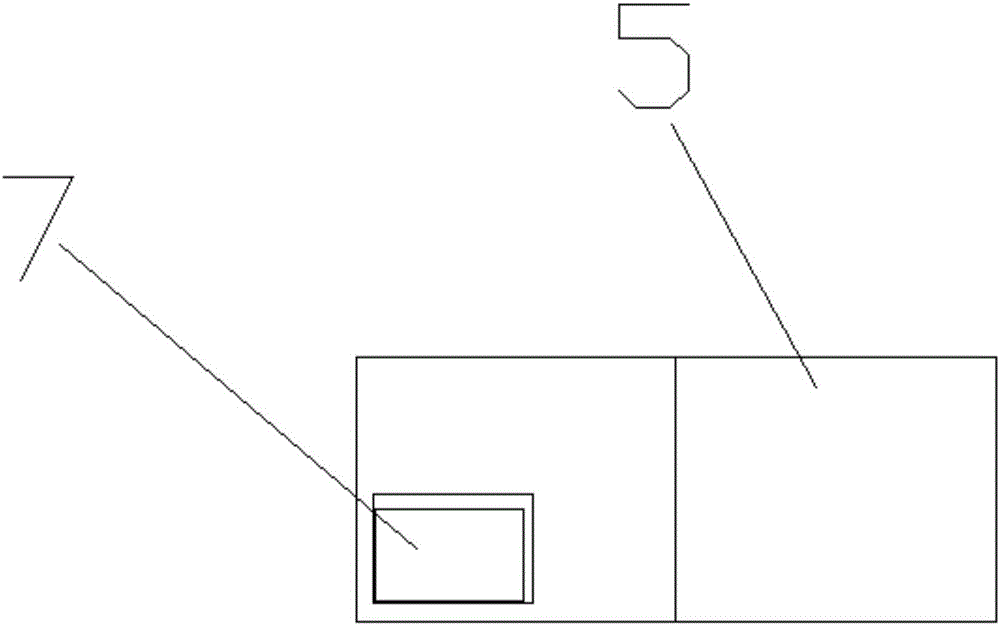

[0015] like figure 1 , figure 2 As shown, a heat-shrinkable film packaging machine in this embodiment includes: a spiral conveying mechanism 1, a heat-shrinkable film coil roller 2, an automatic bag making machine 3, a belt conveying device 4, and a heating furnace 5. The conveying mechanism 1 is located on the left side of the heat-shrinkable film coil roller 2, and the right side of the heat-shrinkable film coil roller 2 is connected to the automatic bag-making machine 3, and the automatic bag-making machine 3 is processed by the belt conveyor 4 It is transmitted to the heating furnace 5, the top of the belt conveyor 5 is provided with a cooling device 6, the heating furnace 5 is located above the belt conveyor 4, and the heating furnace 5 is provided with a temperature sensor 7, the temperature sensor 7 and the controller Connection, the controller is connected with the alarm.

[0016] Further, the automatic bag making machine has a double-row structure with 3 positions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com