Multi-cylinder dressing case inner container conveying mechanism

A technology of conveying mechanism and cosmetic box, which is applied in the direction of conveying objects, transportation and packaging, etc., can solve the problems of low efficiency, unsatisfactory effect, troublesome taking the inner tank, etc., and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

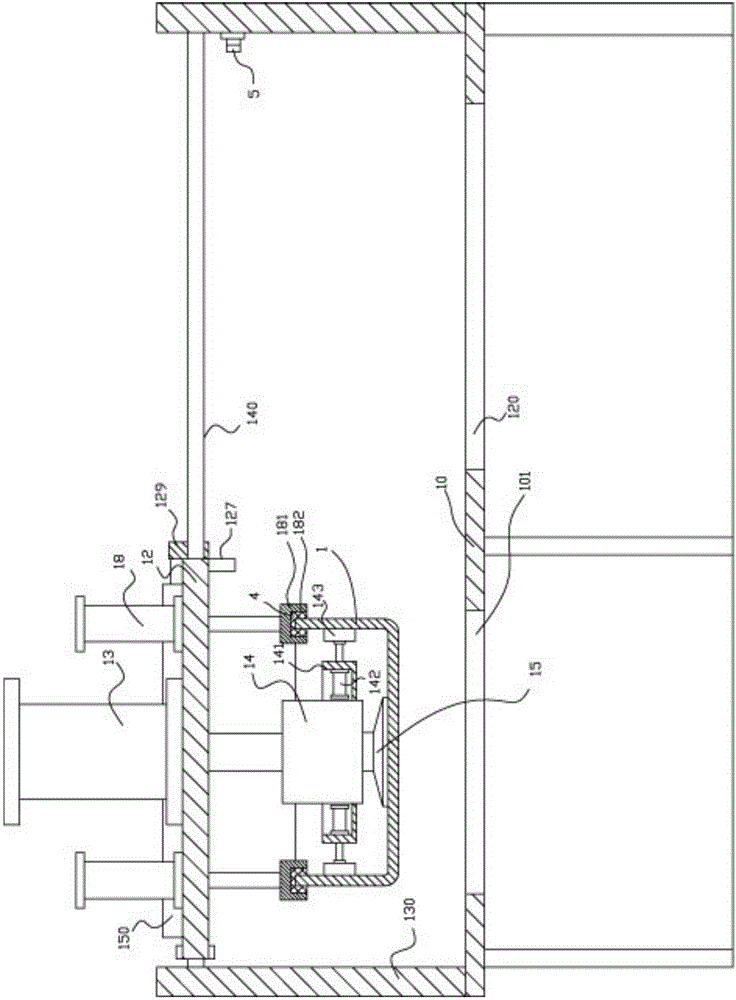

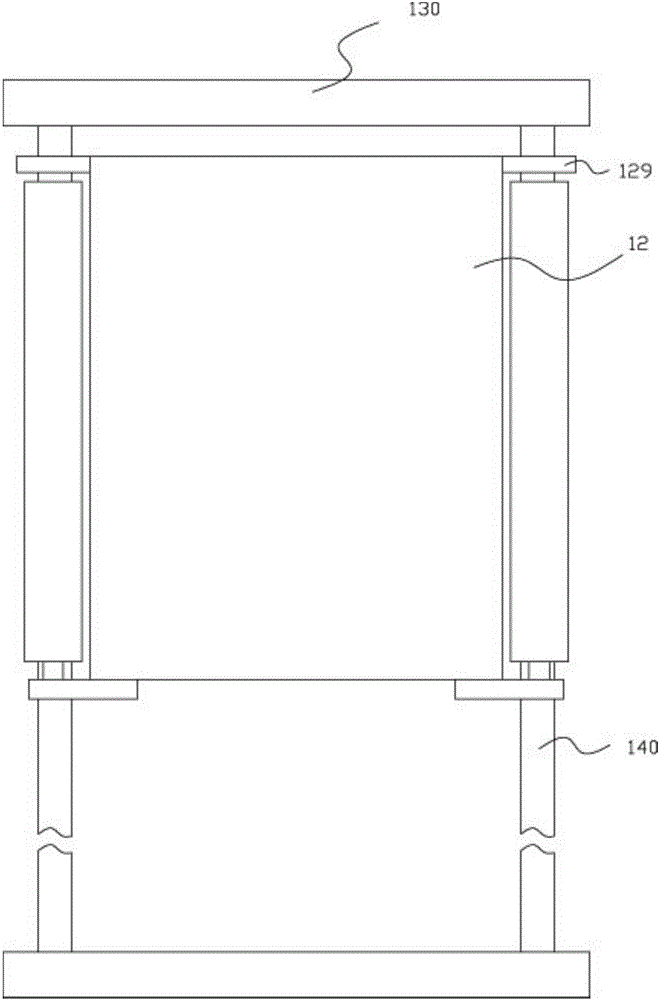

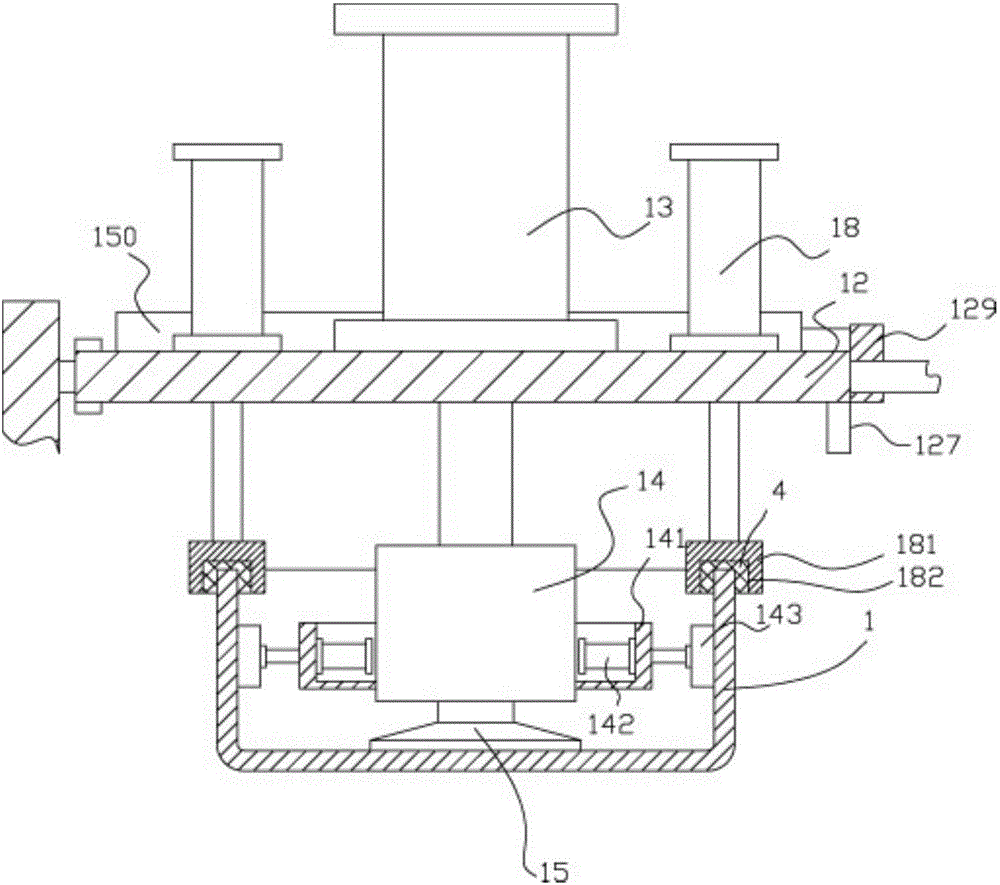

[0014] Example: see Figure 1 to Figure 3 As shown, a multi-cylinder makeup box liner conveying mechanism includes a frame 10, the left middle part of the top plate of the frame 10 has a through hole 101, and the right middle part of the top plate of the frame 10 has a grasping through hole 120 , the left and right sides of the top plate of the frame 10 are fixed with vertical plates 130, and the two ends of the two guide rods 140 are all fixed on the corresponding vertical plates 130, and the two guide rods 140 are located at the front part of the vertical plate 130 and The rear portion, the front and the rear of the left end and the right end of the upper connecting plate 12 are all fixed with a guide block 129, and the guide block 129 is inserted in the guide rod 140, and the top surface at the left side of the two guide rods 140 is fixed with a Transversely move the cylinder 150, the end of the push rod of the laterally move cylinder 150 extends to the right and is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com