Palletizing device for bagged material loading

A stacking device and material bag technology, which is applied in the field of rapid and continuous loading of bagged materials, can solve the problems of low loading efficiency, reduced loading efficiency, and impact on human health, etc., and achieves high loading efficiency and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

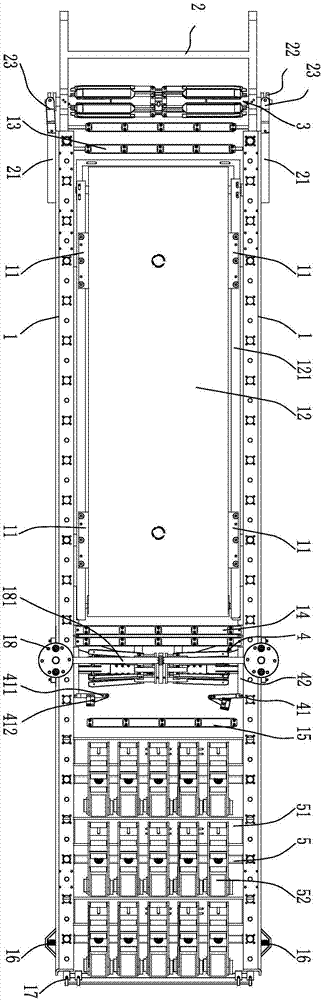

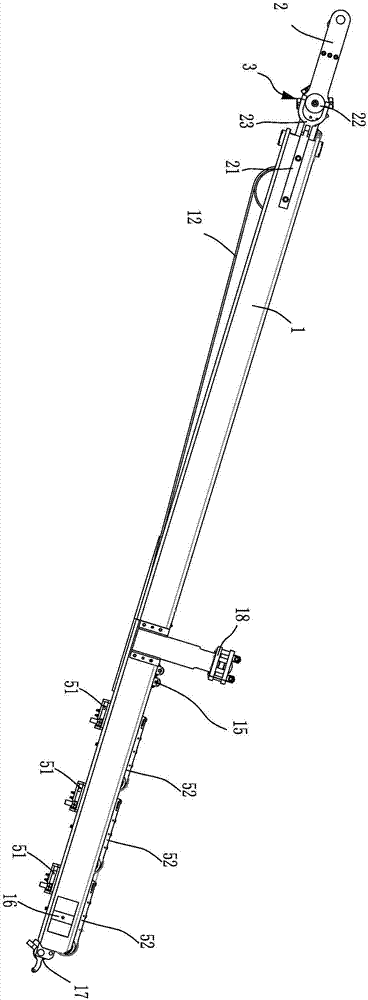

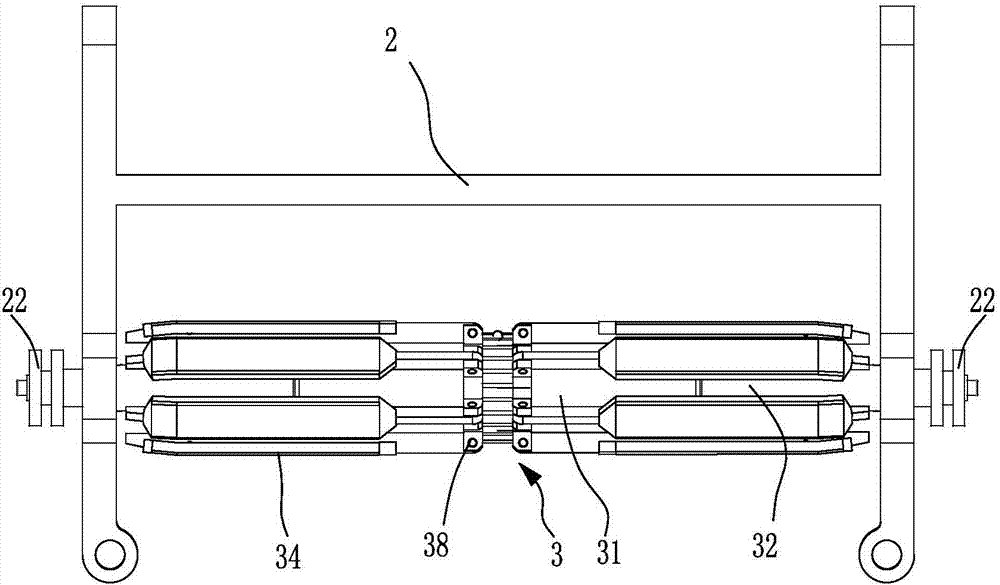

[0028] Such as figure 1 and figure 2As shown, the palletizing device for loading bagged materials into vehicles includes a transition frame 2, which is hinged to the output end of the bag buffer device of the bagged material loading machine during use, and the transition frame 2 is provided with an upper Compensation device, two swing frames 1 are hinged on the output end of the transition frame 2 located in the conveying direction of the bag, and the center line of the hinge pin between the transition frame 2 and the two swing frames 1 and the transition frame 2 and the buffer frame 401 can be hinged The center line of the pin shaft is vertical, which is convenient for the left and right and up and down swings of the two swing frames 1. A swing conveying device is arranged between the two swing frames 1, and an output end of the swing conveying device is located between the two swing frames 1. There is a lower compensating device, and the output end of the lower compensatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com