Synthetic method of cyproconazole intermediate

A technology of cyproconazole and its synthesis method, which is applied in the field of chemistry and chemical engineering, can solve problems such as complex process, high economic cost, and high risk, and achieve the effects of high process fluency, high total reaction yield, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

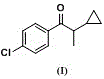

Image

Examples

Embodiment 1

[0028] The synthesis of embodiment 1 compound (III)

[0029]

[0030] In a 500 ml single-necked bottle, add 56g (0.4mol) of p-chlorobenzaldehyde, 150g of toluene, 63.84g (0.84mol) of ethylene glycol methyl ether, and 1.72g (0.01mol) of p-toluenesulfonic acid, and reflux to separate water After 6 hours, triethylamine was added to adjust the pH=7-8, and the solvent was distilled off to obtain 108.2 g of compound (III), with a purity of 97.4% and a yield of 96.3%.

Embodiment 2

[0031] The synthesis of embodiment 2 compound (III)

[0032] In a 500 ml single-necked bottle, add 56g (0.2mol) of p-chlorobenzaldehyde, add 170g of benzene, add 63.84g (0.84mol) of ethylene glycol methyl ether, add 18.25g (0.01mol) of phosphomolybdic acid, reflux and divide water for 6 After 1 hour, triethylamine was added to adjust the pH=7-8, and the solvent was evaporated to obtain 104.9 g of compound (III), with a purity of 96.8% and a yield of 92.6%.

Embodiment 3

[0033] The synthesis of embodiment 3 compound (III)

[0034] In a 500 ml single-necked bottle, add 56g (0.2mol) of p-chlorobenzaldehyde, 180g of toluene, 63.84g (0.84mol) of ethylene glycol methyl ether, and 1.90g (0.01mol) of titanium tetrachloride, and reflux to separate water After 6 hours, triethylamine was added to adjust the pH to 7-8, and the solvent was evaporated to obtain 103.7 g of compound (III), with a purity of 96.4% and a yield of 91.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com