A method for producing methane-rich gas, liquefied petroleum gas and gasoline from synthesis gas

A technology for liquefied petroleum gas and synthesis gas, applied in the field of coal chemical industry, can solve the problems of reduced efficiency and increased energy consumption, and achieve the effect of reducing process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

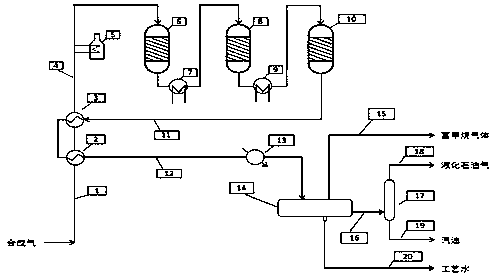

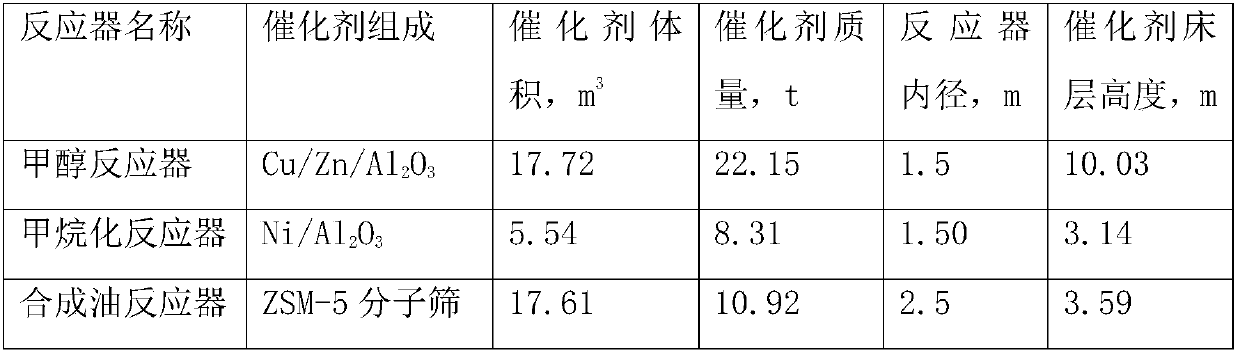

[0060] According to the process shown in the attached figure, the device for producing methane-enriched gas, liquefied petroleum gas and gasoline from syngas was established. The main equipment involved and the catalyst loading conditions are shown in Table 1.

[0061] Table 1. Example 1 reactor and catalyst loading data

[0062]

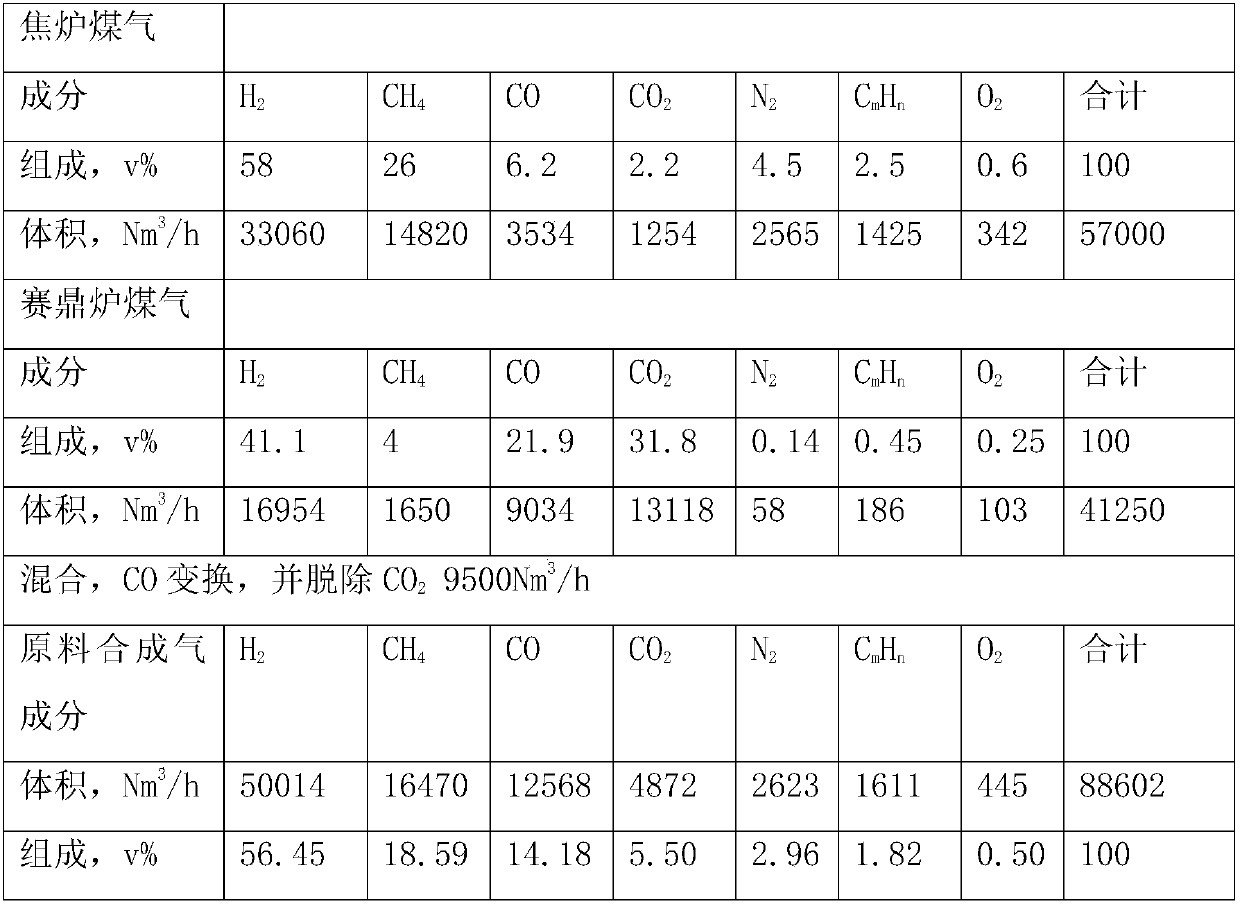

[0063] Embodiment 1 uses coke oven gas and Saiding furnace gas as raw materials. Among them, the coke oven gas is a coke oven gas delivered from a set of 2 million tons / year coking equipment, and the gasifier is a Saiding furnace with a diameter of 3.8m and a coal input of 16.8t / h. After the above two gases are mixed, after purification, CO conversion, CO 2 After removal and other processes, it is used as the raw material gas of this embodiment. The composition and flow rate of relevant gases are shown in Table 2.

[0064] Table 2. The feed gas source and composition of embodiment 1

[0065]

[0066] Raw material gas H of embodiment 1 2 / ...

Embodiment 2

[0087] According to the process shown in the attached figure, the device for producing methane-enriched gas, liquefied petroleum gas and gasoline from syngas is established, and the main equipment and catalyst loading conditions involved are shown in Table 7.

[0088] Table 7. Example 2 Reactor and Catalyst Packing Data

[0089]

[0090] Embodiment 2 uses Saiding furnace gas as raw material. The diameter of the Saiding furnace is 5.0m, the gasification pressure is 5.6MPa, the coal input of a single Saiding furnace is 1500t / d Saiding furnace, and the number of online Saiding furnaces is 10. After the Saiding furnace gasification gas is purified, CO is converted and CO is removed 2 and other operations, the operating volume, gas flow rate and composition of relevant sections are shown in Table 8.

[0091] Table 8. Feed gas source and composition of embodiment 2

[0092]

[0093]

[0094] After purification, conversion and decarburization sections, the pressure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com