Hanger for angle steel galvanization

An angle steel and hanger technology, which is applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of affecting the lifting speed, increase the manufacturing cost, hanging liquid, etc., so as to ensure the effect of galvanizing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

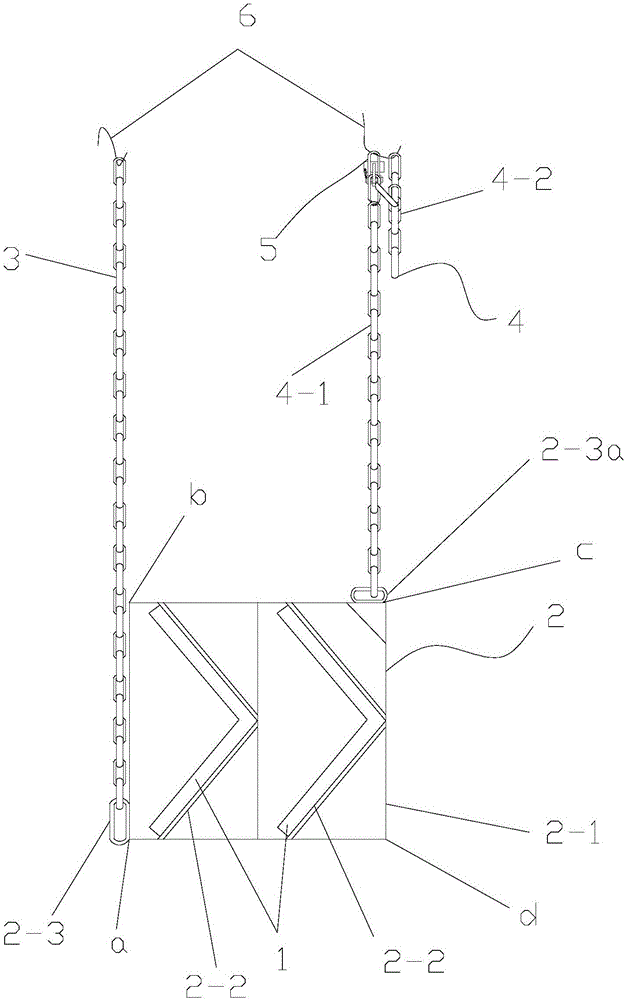

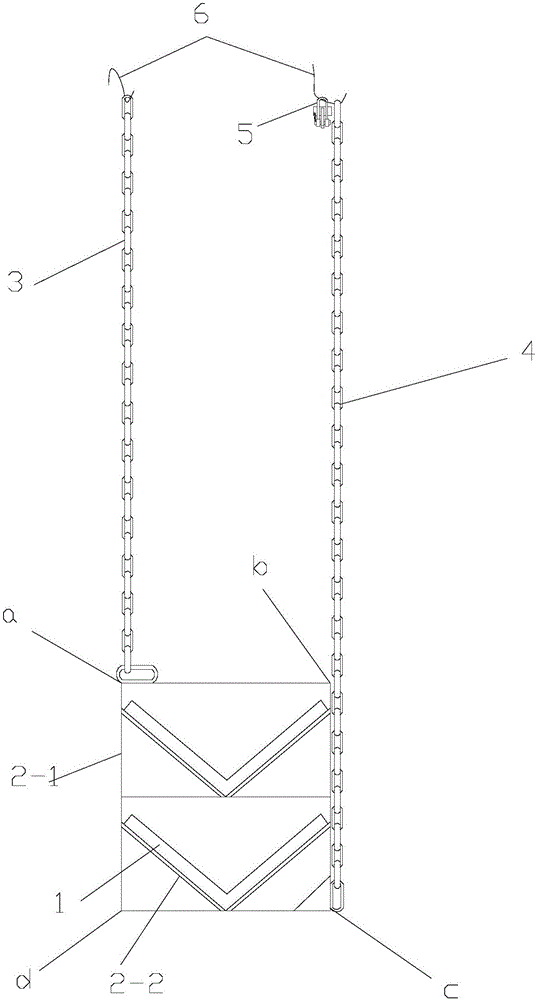

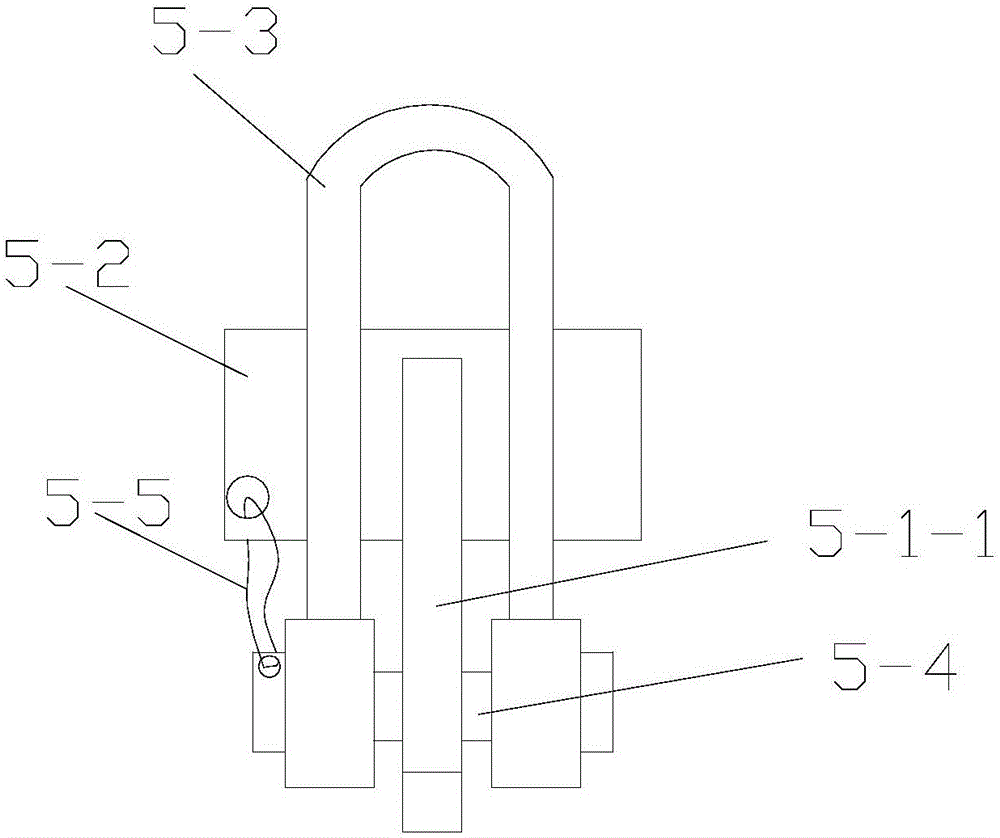

[0019] figure 1 It is a schematic diagram of the overall structure when the suspension body section of the second hanging chain of the present invention is connected with the regulator, figure 2 It is a schematic diagram of the overall structure when the suspension body section of the second hanging chain of the present invention is separated from the adjuster, image 3 It is a structural schematic diagram of the regulator of the present invention, Figure 4 for image 3 Left view, as shown in the figure: the hanger for galvanizing angle steel in this embodiment includes a hanger 2 for placing angle steel 1 and a hanging chain for hanging hanger 2, and the hanging chain includes the first hanging chain 3 and the second hanging chain Two hanging chains 4, the first hanging chain 3 and the second hanging chain 4 respectively correspond to the two diagonal vertices of the hanger 2 and are flexibly connected. As shown in the figure, the hanger includes the first apex a, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com