Frame support arch tunnel lining structure

A frame support and tunnel technology, which is applied in the field of hard rock tunnels or tunnel lining structures in karst areas, and can solve problems such as rising groundwater levels, inability to effectively divert and drain accumulated water, and inability to divert drainage in a timely manner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

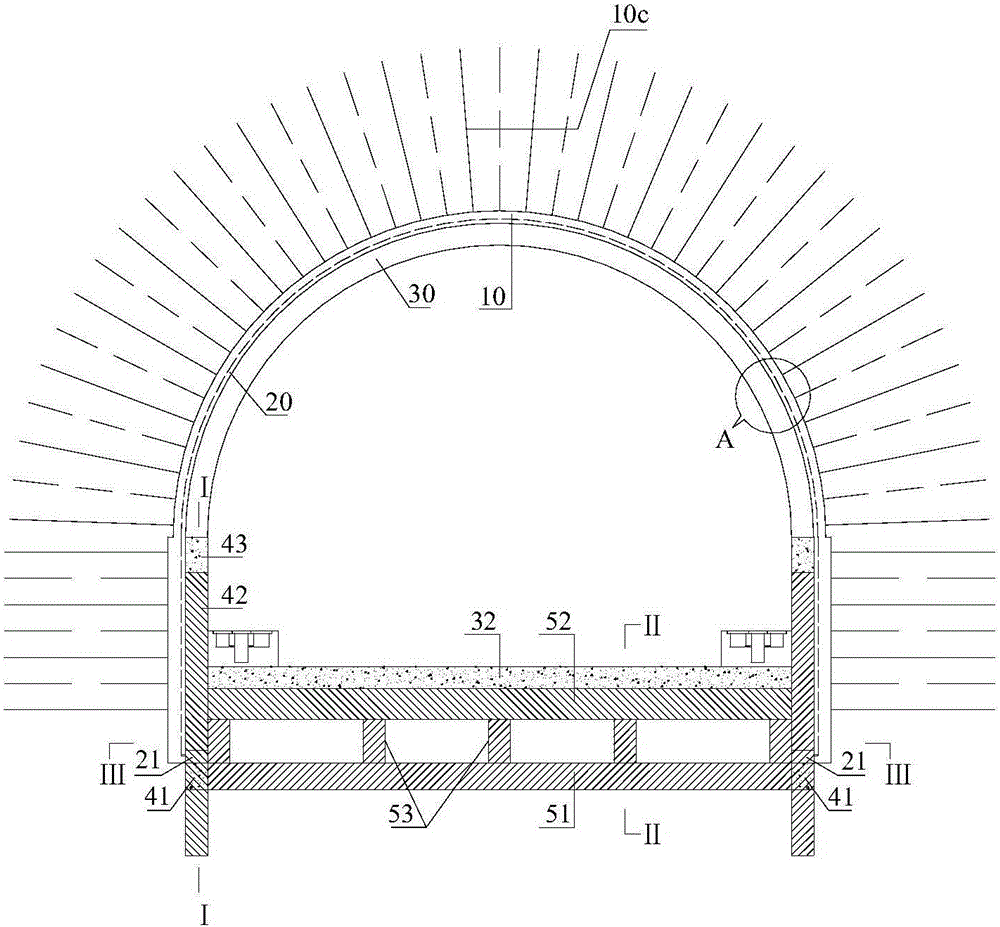

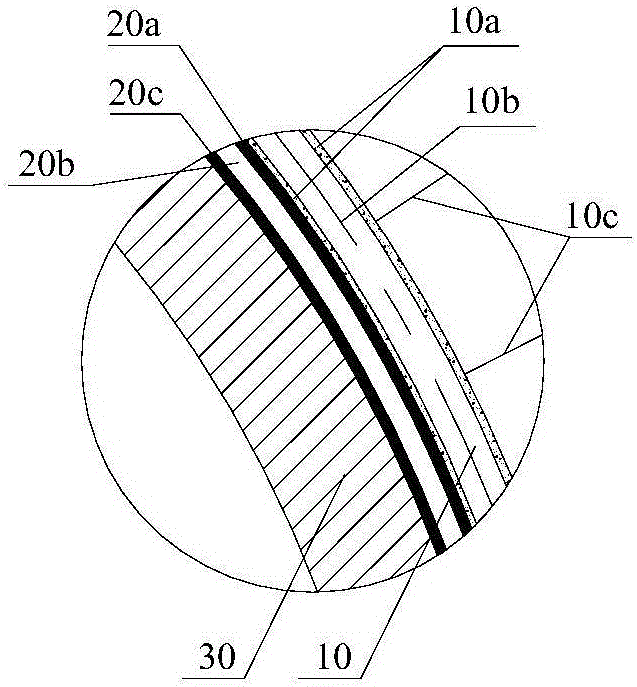

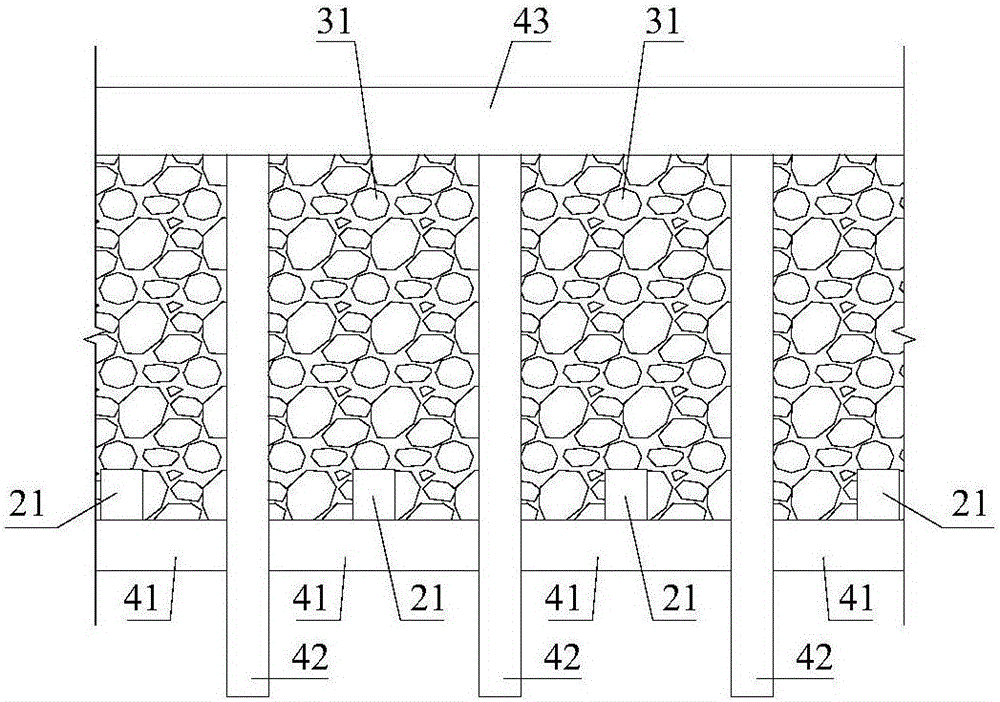

[0018] refer to figure 1 , the frame-supported arch tunnel lining structure of the present invention includes an arch wall primary support structure 10, a secondary lining structure and a waterproof and drainage system between the two, and the secondary lining structure includes a vault section 30, a side wall section and an inverted arch part. The side wall section is a frame support structure of the side wall, which is used as the load-bearing structure of the vault section 30, replacing the molded concrete for the secondary lining of the side wall in the traditional lining, which can not only save concrete, but also facilitate the drainage of groundwater behind the side wall. The inverted arch section is a tunnel bottom frame structure with an internal cavity. The bottom plate 32 is laid on the top surface of the tunnel bottom frame structure. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com