Active Torque Type Locknuts

An anti-loosening nut and active power technology, applied in the direction of nuts, screws, bolts, etc., can solve the problem of reducing the axial clamping force, and achieve the effects of improving reliability, prolonging maintenance cycle, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

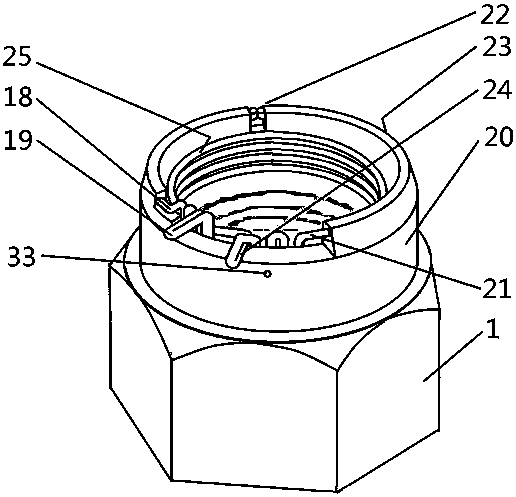

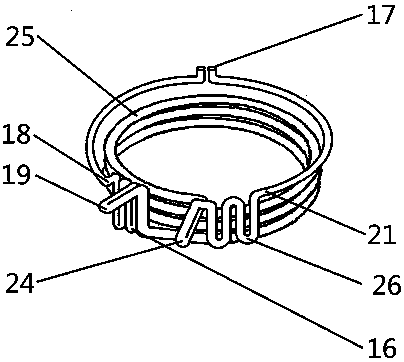

[0059] Below in conjunction with accompanying drawing, the present invention is further described:

[0060] like figure 1 , 2 As shown, the present invention is composed of a lock nut 1 and a screw sleeve 25. The lock nut 1 can be of any shape or type, and the lock nut 1 and the matched screw helical form can be left-handed or right-handed. In this embodiment, it is Hexagonal nut, the screw way is right hand. The upper part of the locking nut 1 is provided with a threaded sleeve protection shell 20, and the lower part is a screw thread, and its function is equivalent to that of a conventional nut. The inner surface of the screw sleeve protective shell 20 is a toothless smooth surface, and the inner diameter is suitable for placing the screw sleeve 25 . The screw sleeve 25 is installed in the screw sleeve protective shell 20 . like figure 2As shown, the screw sleeve 25 is made of steel wire, and its cross-section can be any shape, preferably a rhombus or a circle, in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com