A leaf spring composite force bench test mechanism

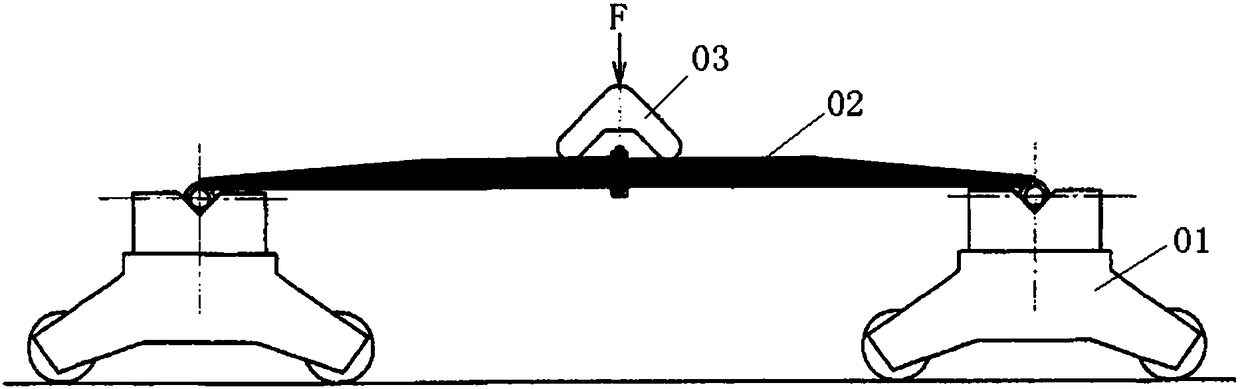

A bench test and leaf spring technology, applied in the direction of applying stable torsion to test material strength, elasticity test, machine/structural component test, etc., can solve the problem of safety, stability, reliability and test accuracy High, incapable of leaf spring longitudinal torsion and transverse torsion tests, etc., to achieve the effects of long life, reduced maintenance, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

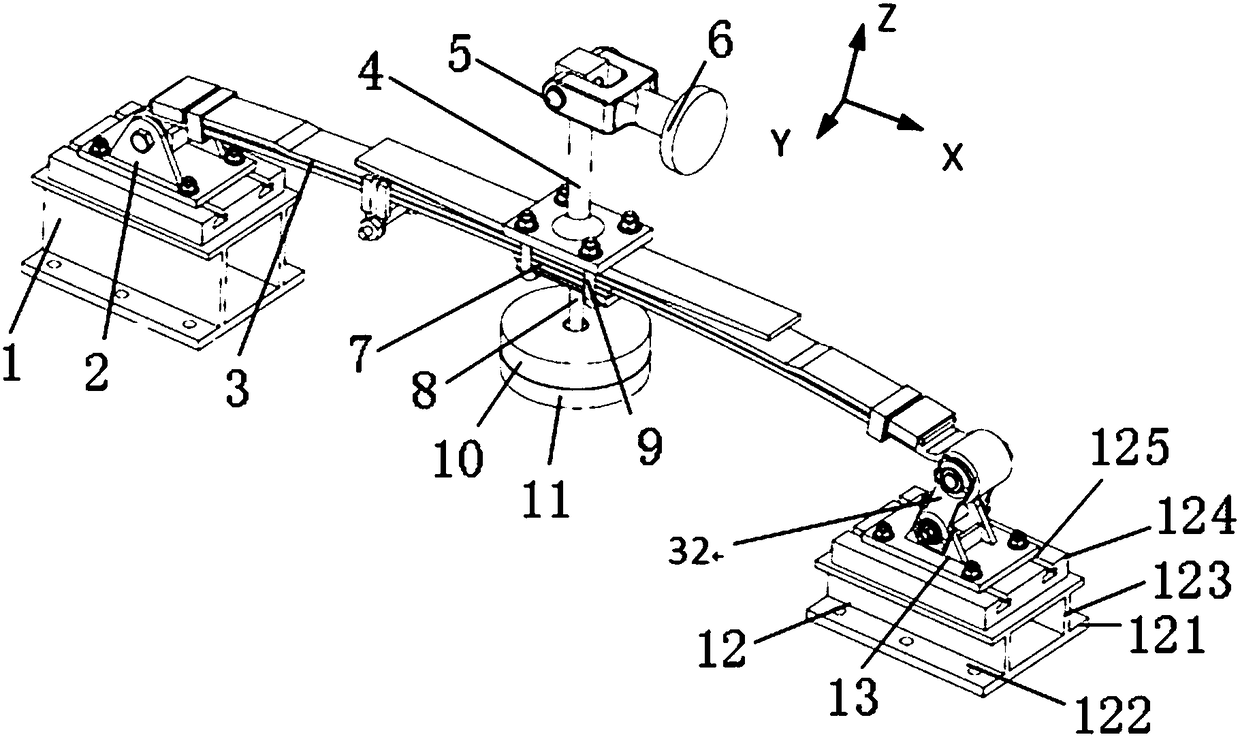

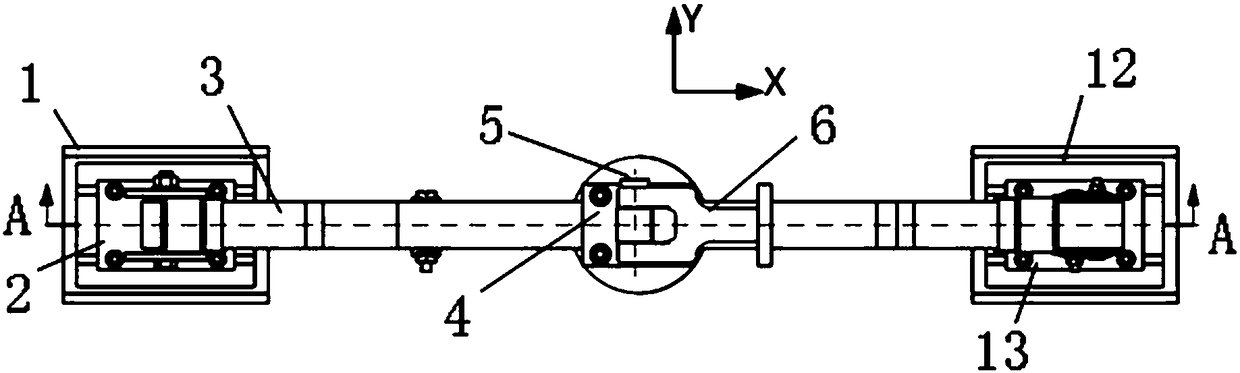

[0049] The invention provides a leaf spring composite force bench test mechanism, such as Figure 2 to Figure 8 As shown, it includes front support 1, rear support 12, roll lug bracket 2, lifting lug bracket 13, leaf spring assembly 3 for test, backing plate with force arm 4, pin shaft 5, fork-shaped test force input shaft 6 , backing plate 7, backing plate 8, U-bolt 9, upper loading 10 and lower loading 11 with load-bearing rod.

[0050] Both the front support 1 and the rear support 12 are fixed on the ground. In other embodiments of the application, the front support and the rear support can be fixed on the test bench as required wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com