DC insulator insulation test device and DC insulator insulation test method

An insulation test, DC insulation technology, applied in the direction of measuring devices, testing dielectric strength, instruments, etc., can solve the problems of test failure, insulation support can not meet the requirements of DC insulator insulation test, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

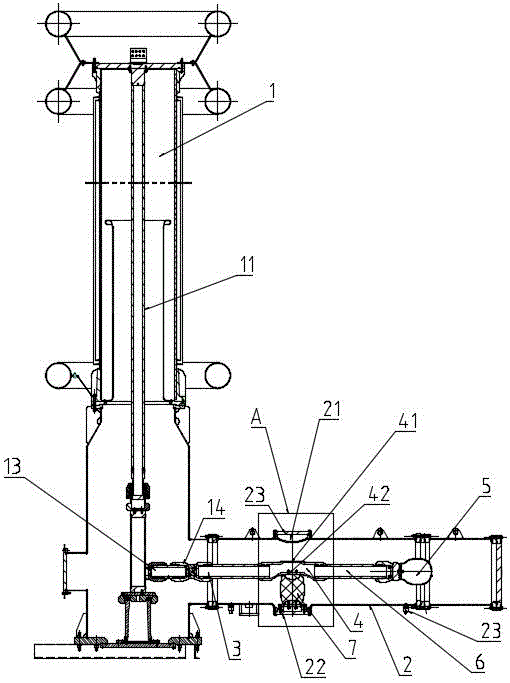

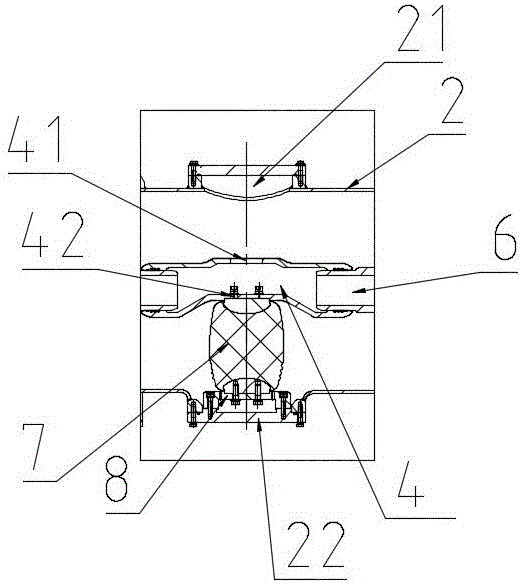

Image

Examples

specific Embodiment 2

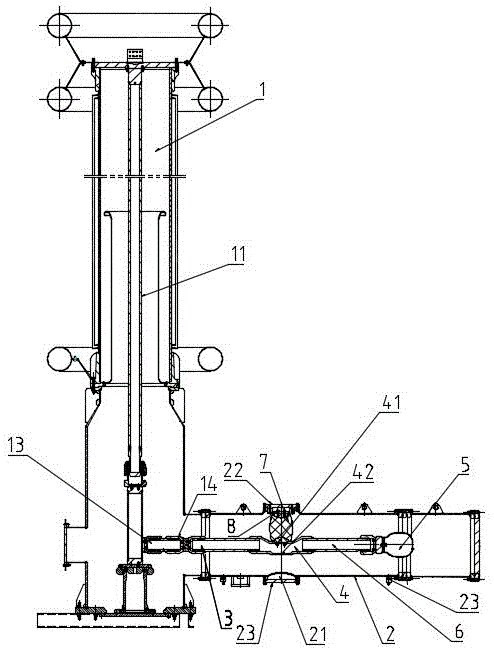

[0032] Specific embodiment 2 of the DC insulator insulation test device of the present invention, the difference between the DC insulator insulation test device in this embodiment and the above-mentioned embodiment 1 is only: as image 3 As shown, the insulator ground terminal mounting base 8 is set on the upper end of the test cylinder 2, correspondingly, the test cylinder 2 is provided with a ground terminal sealing cover 22 which is arranged above the test cylinder, and the removable sealing cover 23 is arranged on the top of the test cylinder 2. The end seals are along the diametrically opposite sides of the test cylinder. A screw fixing hole 42 for fixing the insulator is provided on the side of the insulator high-voltage end mounting base 4 facing the grounding end mounting base, and a screw dismounting opening 41 is provided on the side facing the insulator dismounting opening. Since the mounting base of the insulator ground terminal can also be set on the top of the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com