Reactor control rod driving wire buffer structure

A buffer structure and control rod technology, which is applied in the control of nuclear reactions, reactors, and reduction of greenhouse gases, etc., can solve the problems that the buffer form is no longer applicable, and the control rod components cannot be popularized, etc., and achieve good buffering effect and convenient rod drop buffering requirements , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

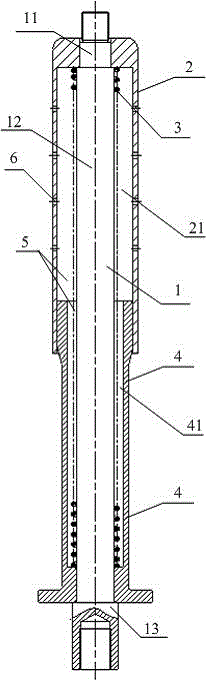

[0026] Such as figure 1 As shown, the buffer structure of the reactor control rod drive line includes a buffer, a connecting rod 1, and a return spring 3, wherein:

[0027] There is a water cavity 5 inside the buffer, and a number of water holes 6 are opened on the wall of the water cavity 5;

[0028] The connecting rod 1 is arranged in the water cavity 5, and the upper and lower ends of the connecting rod 1 pass through the buffer respectively, the upper end is used for connecting the driving rod, and the lower end is used for connecting the control rod assembly;

[0029] The buffer includes a buffer upper part 2 and a buffer lower part 4, the buffer upper part 2 is fixedly connected with the connecting rod 1, the buffer lower part 4 can slide relative to the connecting rod 1, that is, the buffer lower part 4 can slide in the vertical direction, and the rod can be dropped In the later stage, the lower part of the buffer 4 contacts the support and remains still, and the upper...

Embodiment 2

[0036] On the basis of Embodiment 1, in this embodiment, the buffer is improved as follows:

[0037] The buffer upper part 2 is provided with a first cavity 21, the buffer lower part 4 is provided with a second cavity 41, the first cavity 21 and the second cavity 41 communicate to form a water cavity 5, and the first The cross sections of the cavity 21 and the second cavity 41 are circular.

[0038] The upper end of the buffer lower part 4 extends into the first cavity 21, and there is an annular gap between the cavity wall on the side of the first cavity 21 and the connecting rod 1, and the cavity on the side of the second cavity 41 There is also an annular gap between the wall and the connecting rod 1. The water flow holes 6 are opened on the upper part 2 of the buffer and run through the cavity wall on the side of the second cavity 41. These water flow holes 6 are in the cavity of the first cavity 21. The walls are evenly distributed in the circumferential direction, and m...

Embodiment 3

[0044] On the basis of Embodiment 1, in this embodiment, the buffer is improved as follows:

[0045] A first cavity 21 is provided in the upper part 2 of the buffer, and a second cavity 41 is provided in the lower part 4 of the buffer. The first cavity 21 and the second cavity 41 communicate to form a water chamber 5. The buffer The lower end of the upper part 2 of the device extends into the second cavity 41, and the water flow holes 6 are opened on the lower part 4 of the buffer, and these water flow holes 6 can be arranged in multiple rows from top to bottom.

[0046] There is a gap between the lower end of the buffer upper part 2 and the bottom of the second cavity 41, that is, the bottom of the second cavity 41 does not contact the lower end of the buffer upper part 2, so as to prevent the buffer upper part 2 from filling the entire second cavity. Cavity 41, because the second cavity 11 needs to be filled with water for buffering.

[0047] The upper end of the buffer upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com