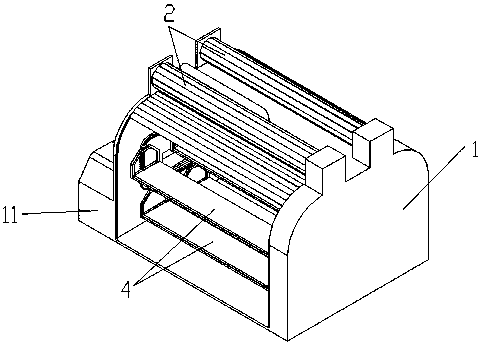

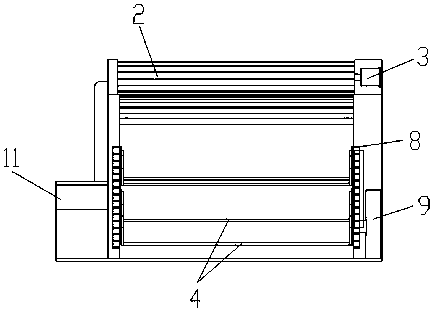

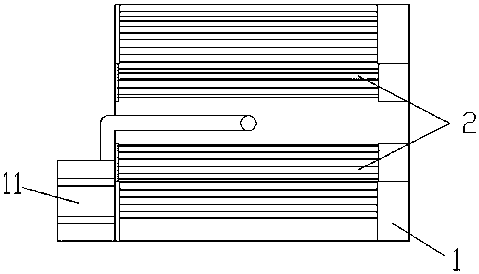

Stereoscopic circulating storage type drying room

A technology of three-dimensional circulation and drying room, applied in the field of drying, can solve the problems of difficulty in handling, difficulty in meeting the diversified product drying needs of enterprises, narrow access passages, etc., and achieve the effect of saving manual handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0043] Under such a structure, more automated storage and handling operations can be realized. When the opening of the lifting shutter door 2 reaches the maximum, the crane can directly hoist and transport the product to the loading pallet 4, thereby reducing the handling work intensity of the operator to the greatest extent. Combining the manual control of the reduction motor 9 and the circulating chain, the products are stored on the loading pallet 4 one by one, and then the motor 3 is turned on to automatically circulate the mode, and the circulating chain drives the loading pallet 4 to circulate in the drying room 1, Waiting for drying to maximize the use of drying area space and save the area occupied by the site. With the adjustable speed cycle of the geared motor 9 driving the loading pallet 4, and the temperature control device of the infrared oven lamp 10, combined with the personalized pallet fixing fixture, the drying operation matching the variable output requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com