A compression nut and a connector using the compression nut

A technology for pressing nuts and connectors, applied in the field of pressing nuts and connectors, can solve problems such as low disassembly and assembly efficiency, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

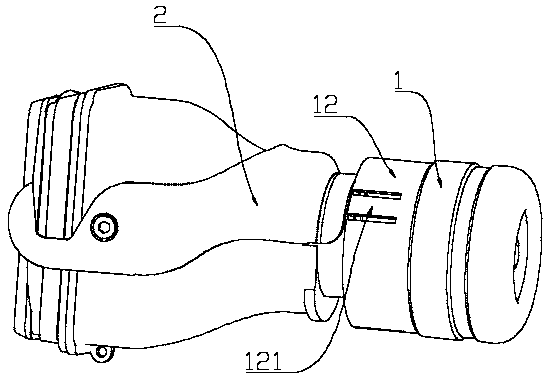

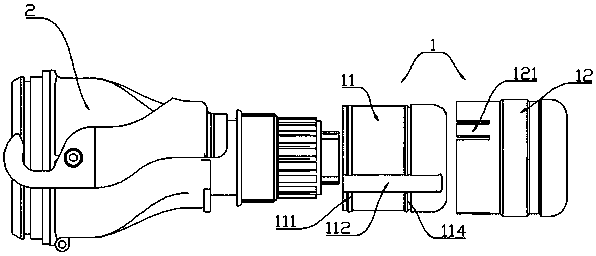

[0022] A specific embodiment of a connector of the present invention, such as Figure 1 to Figure 4 As shown, the connector includes a compression nut 1 and a connector housing 2 , and the compression nut 1 and the connector housing 2 are screwed together.

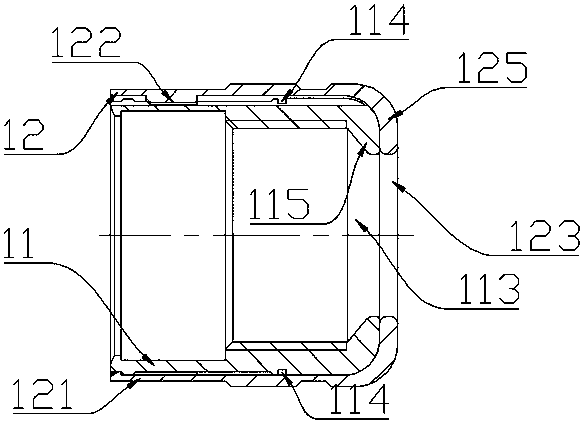

[0023] The compression nut 1 comprises a nut body 11. The nut body 11 has a threaded hole extending in the front-rear direction. There are 12 telescoping caps. The rear end of the telescopic cap is provided with a telescoping cap threading hole 123 surrounded by the telescopic cap tail turning edge 125, and the connecting wire of the connector passes through the main body threading hole 113 and the telescoping cap threading hole 123 accordingly. The telescopic cap 12 is provided with a hand-held operation part 124 extending out from the rear side of the nut body 11 for twisting the nut body when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com