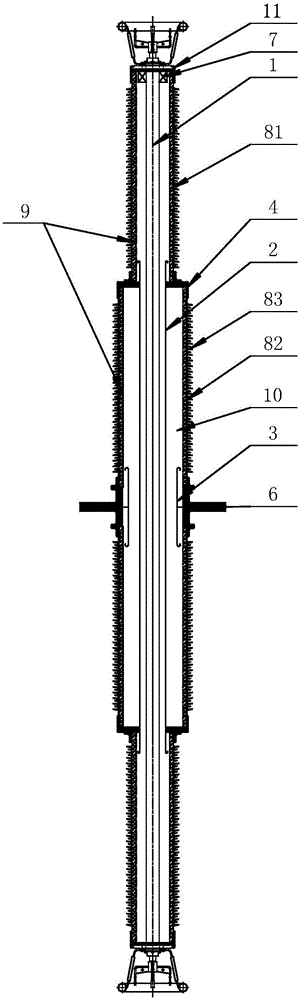

Extra-high-voltage DC wall-penetrating sleeve

An ultra-high voltage DC, through-wall bushing technology, applied in insulators, electrical components, insulators and other directions, can solve the problems of uneven external voltage distribution, increased manufacturing difficulty, long production cycle, etc., to improve partial discharge performance, weight change. The effect of light weight and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with examples. However, the invention is not limited to the examples given.

[0021] like figure 1 As shown, the UHV DC wall bushing of this embodiment includes: insulating parts fixed on both sides of the grounding cylinder, high-voltage electrodes penetrating through the insulating part, and grounding electrodes fixed on the inner wall of the grounding cylinder. The grounding cylinder is equipped with end-screen measuring terminals, current transformers and flange structures for installation on the wall. The casing ensures the sealing of the end of the casing through the spring structure 7 and the seal, and the casing is filled with SF6 insulating gas 10 . The outer end of the insulating part is provided with an end plate. Take the upper insulation part in the figure as an example (the insulation structure on both sides of the grounding cylinder is the same), the insulation part has two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com