Toroidal continuously variable transmission

A continuously variable transmission, annular technology, used in couplings, rigid shaft couplings, friction transmission devices, etc., can solve the problems of lubricating oil pollution and poor lubrication state, and achieve the effect of improving support rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

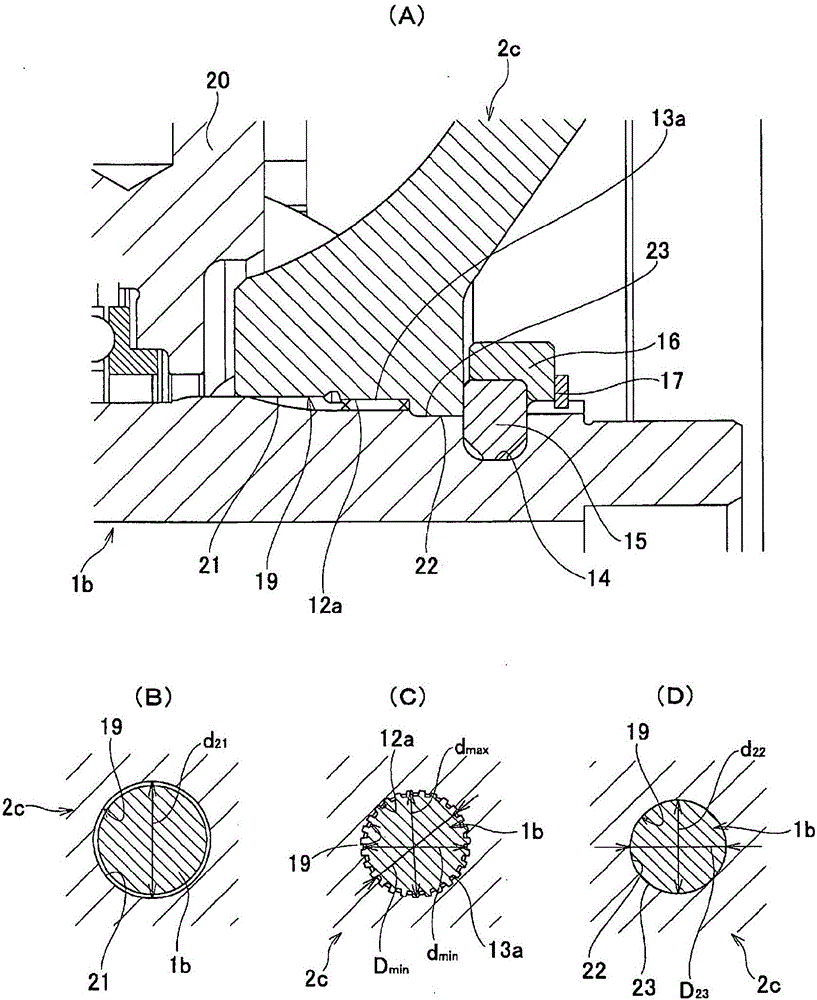

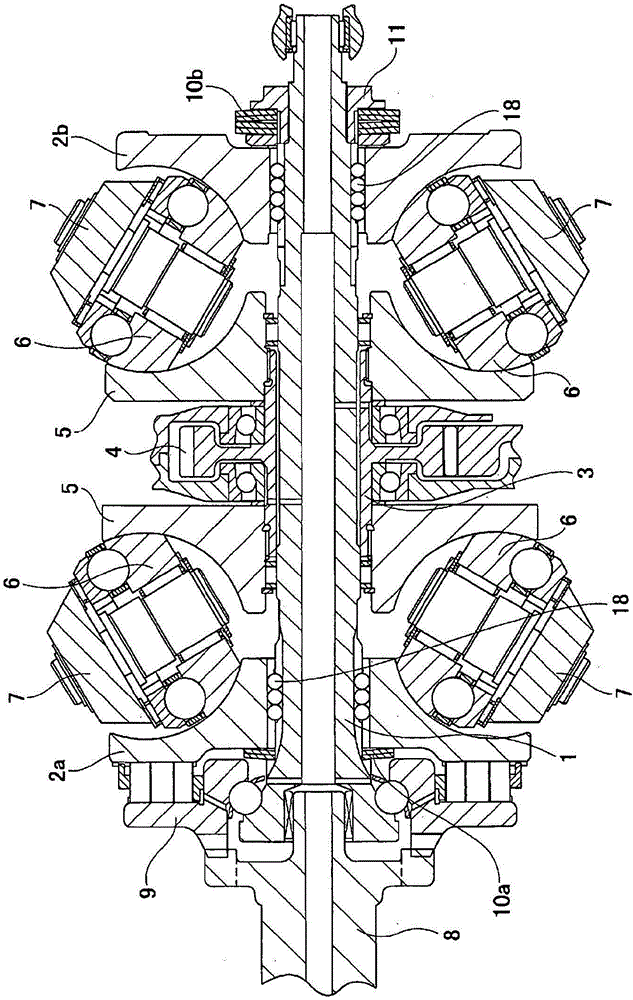

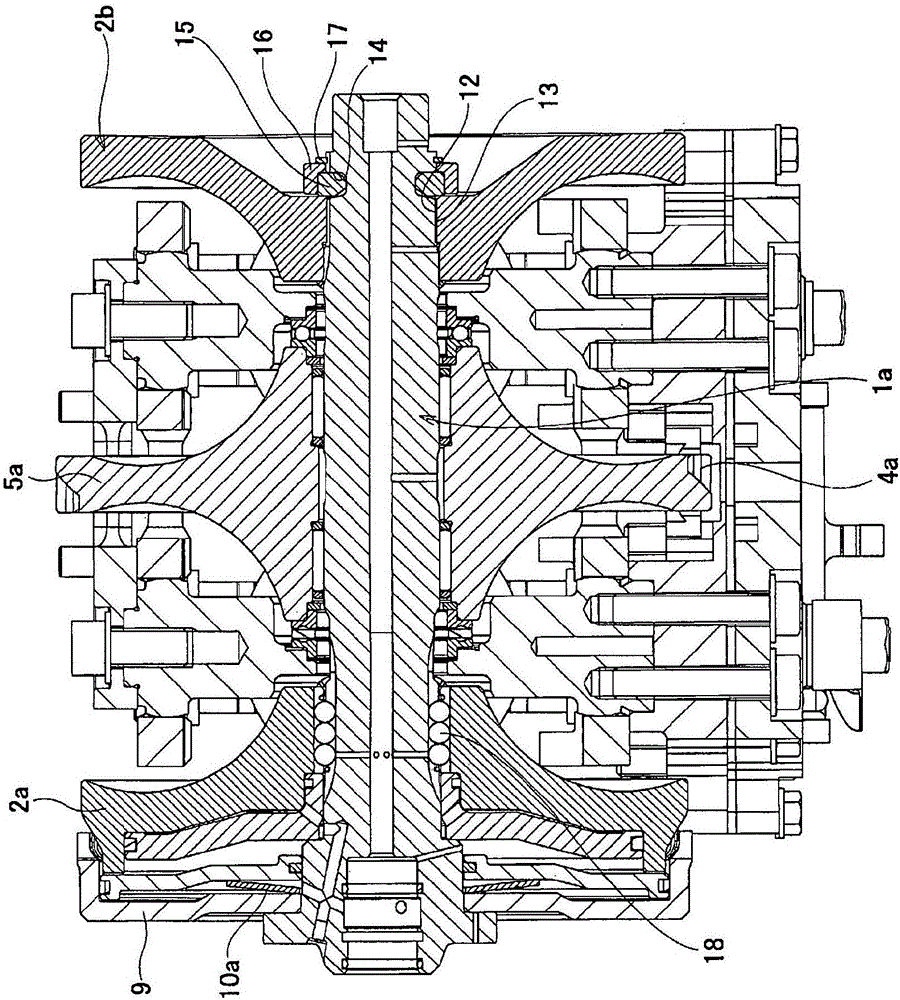

[0041] figure 1 An example of an embodiment of the toroidal continuously variable transmission of the present invention is shown. In this case the toroidal continuously variable transmission with Figure 3 ~ Figure 6 The second example of the conventional toroidal continuously variable transmission shown similarly includes an input rotating shaft 1b as a rotating shaft, a pair of input side discs 2a, 2c as a pair of outer discs, an output side disc 5a as an inner disc, multiple A trunnion 7 as a supporting member, a plurality of power rollers 6, a pressing device 9a, and a locking ring 15 as a locking member.

[0042] The pair of input disks 2a and 2c is composed of one input disk 2a disposed around one end of the input shaft 1b and the other input disk 2c disposed around the other end of the input shaft 1b. The one input side disk 2 a and the other input side disk 2 c each have an axially one side surface facing axially inward of the input rotary shaft 1 b as a circular cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com