Glass-wiping robot with lift-type traveling mechanism and glass-wiping method thereof

A glass-wiping robot and traveling mechanism technology, applied in instruments, manipulators, simulators, etc., can solve the problems of inflexible commutation, repeated wiping, movement path restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

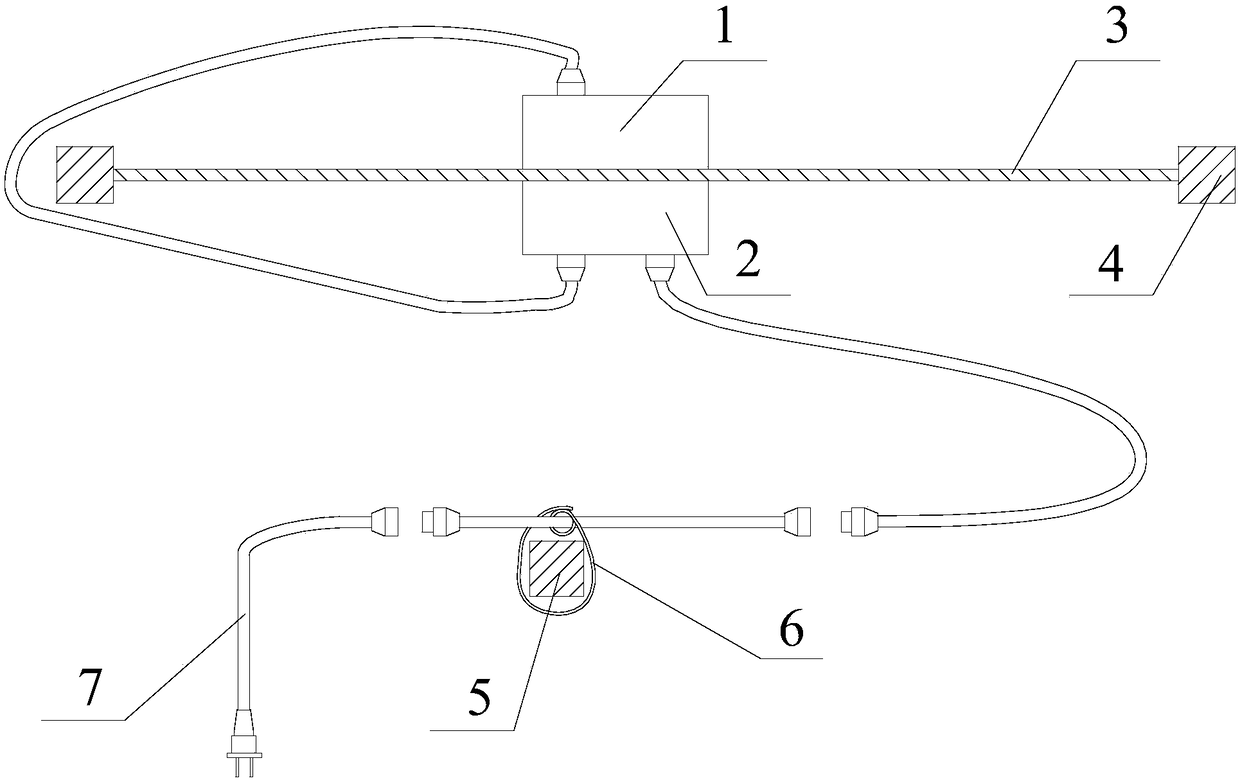

[0077] Such as figure 1As shown, the glass-wiping robot with a lift-type walking mechanism of the present invention includes a driving part 1 and a driven part 2 which are respectively arranged on the inner side of the glass 3 and the outer side of the glass 3 and cooperate with each other, and are used for safety protection and are used for A safety power line 7 that supplies power to the active part 1 and the driven part 2;

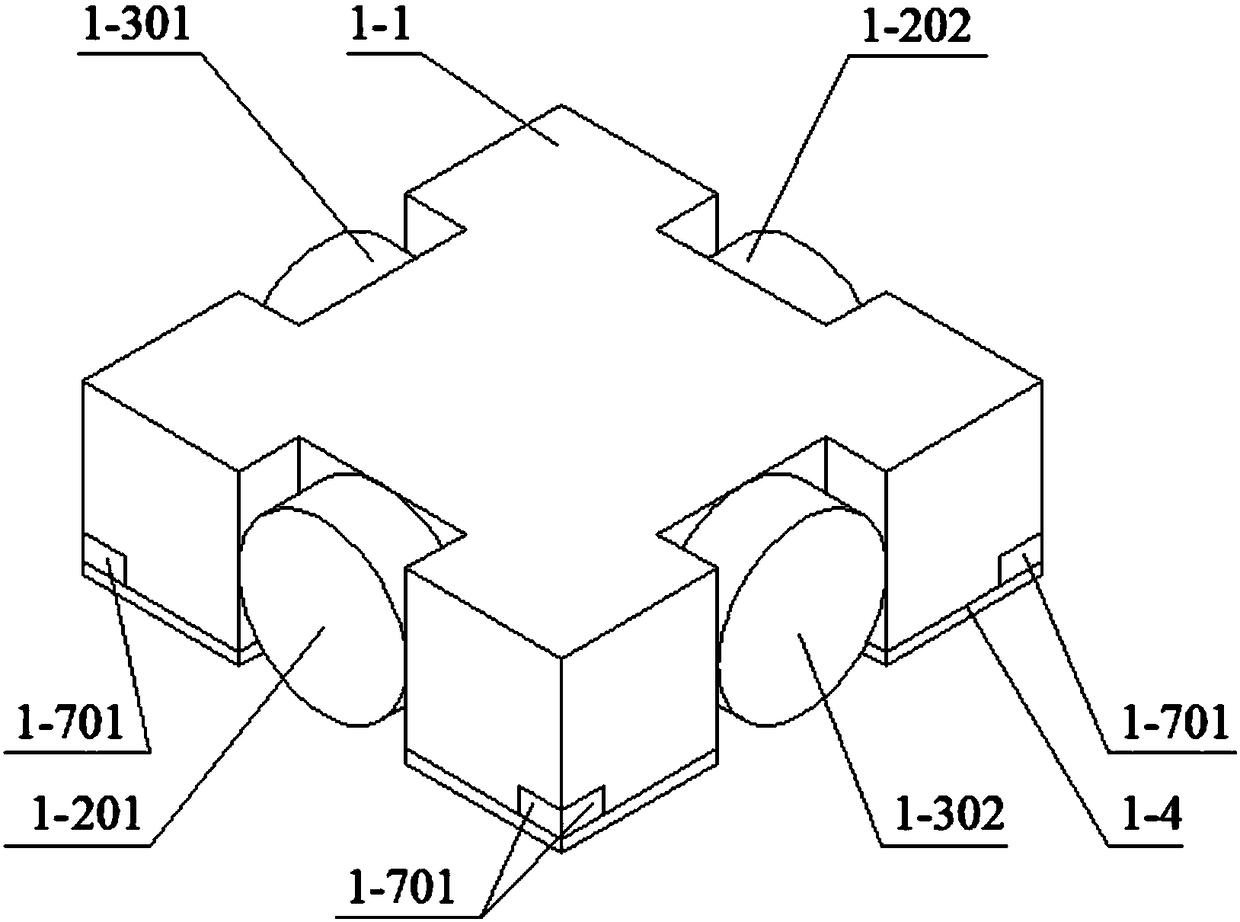

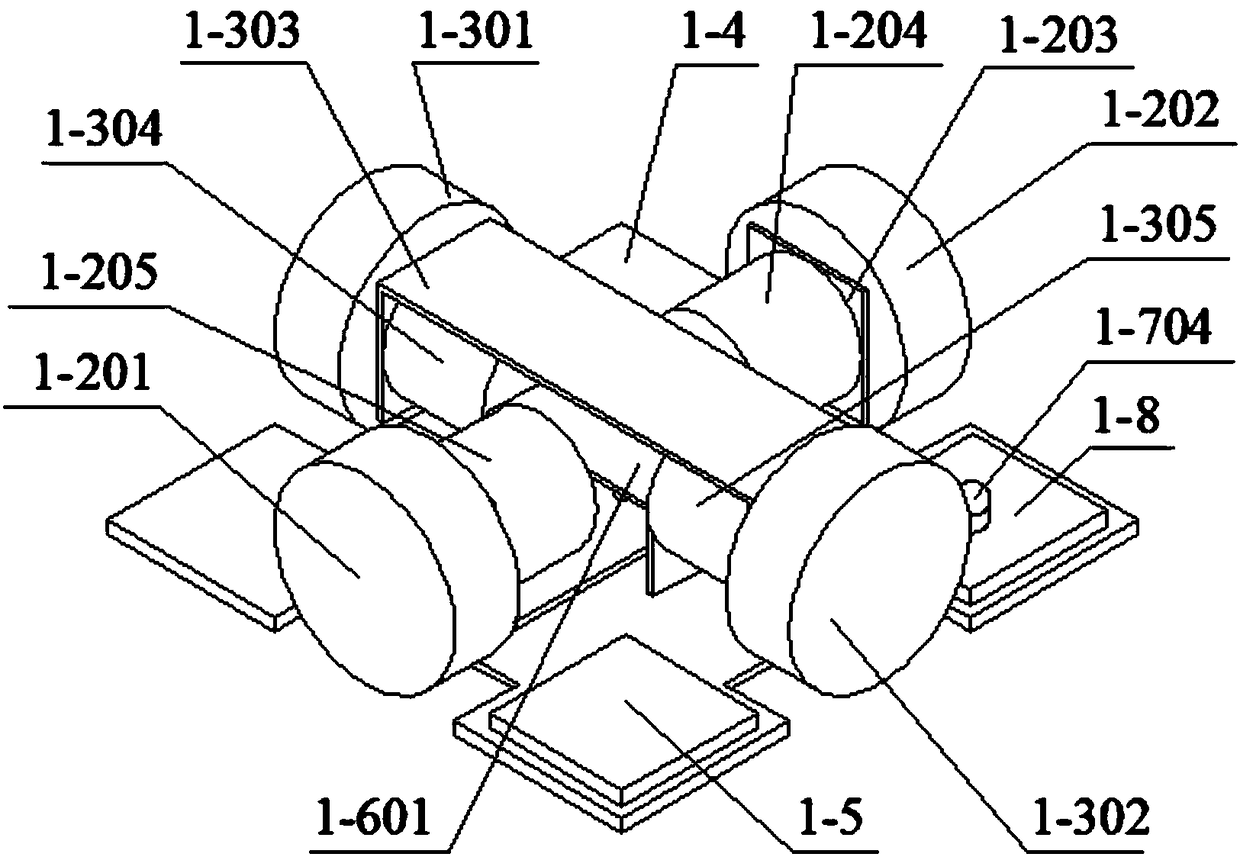

[0078] Such as Figure 2 ~ Figure 6 As shown, the active part 1 includes the active part bottom plate 1-4 and the active part housing 1-1 fixedly connected to the top of the active part bottom plate 1-4, and the first driving wheel set, the second driving wheel set, and the active part lifting unit, the active part sensing unit, the active part controller 1-5 and the active part energy source 1-8, and the bottom surface of the active part bottom plate 1-4 is fixedly connected with the active part rag 1-9 and the active part magnetic block 1 -10; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com