Filtering device for filtering conveying medium

A technology of conveying medium and filter device, which is applied in the field of pipeline filtration, which can solve the problems of inconvenient filter cleaning, complicated cleaning process, and low efficiency, and achieve the effects of reducing impact, improving cleaning efficiency, and simple cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

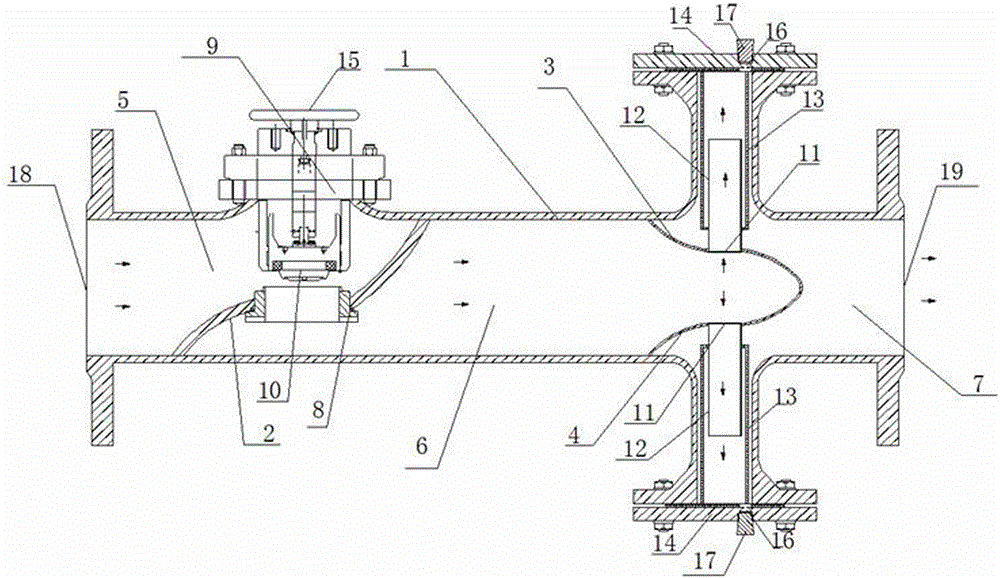

[0024] As a preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0025] A filter device for conveying medium filtration, including a filter body 1, the inner cavity of the filter body 1 is divided into a cut-off cavity 5, a medium cavity 6 and a filter cavity 7 by a partition part I2, a partition part II3 and a partition part III4 One end of the partition part I2 is connected to the upper wall of the filter body 1, the other end is connected to the lower wall of the filter body 1, one end of the partition part II3 is connected to the upper wall of the filter body 1, and the other end is connected to the partition part One end of III4 is connected, and the other end of the partition part III4 is connected to the lower wall of the filter body 1; the partition part I2, the partition part II3 and the partition part III4 are surrounded to form a medium chamber 6; the partition part I2 is provided with The opening part 8...

Embodiment 2

[0027] As another preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0028] A filter device for conveying medium filtration, including a filter body 1, the inner cavity of the filter body 1 is divided into a cut-off cavity 5, a medium cavity 6 and a filter cavity 7 by a partition part I2, a partition part II3 and a partition part III4 One end of the partition part I2 is connected to the upper wall of the filter body 1, the other end is connected to the lower wall of the filter body 1, one end of the partition part II3 is connected to the upper wall of the filter body 1, and the other end is connected to the partition part One end of III4 is connected, and the other end of the partition part III4 is connected to the lower wall of the filter body 1; the partition part I2, the partition part II3 and the partition part III4 are surrounded to form a medium cavity 6; the partition part I2 is provided with The opening p...

Embodiment 3

[0031] As another preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0032]A filter device for conveying medium filtration, including a filter body 1, the inner cavity of the filter body 1 is divided into a cut-off cavity 5, a medium cavity 6 and a filter cavity 7 by a partition part I2, a partition part II3 and a partition part III4 One end of the partition part I2 is connected to the upper wall of the filter body 1, the other end is connected to the lower wall of the filter body 1, one end of the partition part II3 is connected to the upper wall of the filter body 1, and the other end is connected to the partition part One end of III4 is connected, and the other end of the partition part III4 is connected to the lower wall of the filter body 1; the partition part I2, the partition part II3 and the partition part III4 are surrounded to form a medium chamber 6; the partition part I2 is provided with The opening p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap