A vertical gear hobbing machine

A gear hobbing machine and gear hobbing technology, which is applied in the direction of gear cutting machines, gear teeth, mechanical equipment, etc., can solve the problems of how to arrange and connect the relationship unclear, and achieve the effects of reducing overall weight, high angle control accuracy, and improving the convenience of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

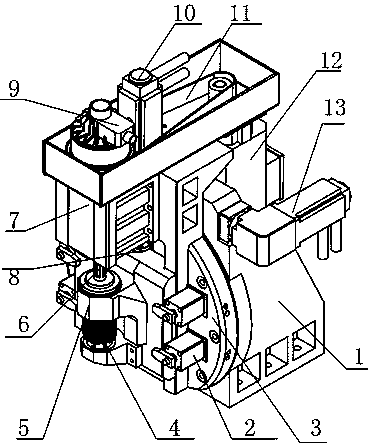

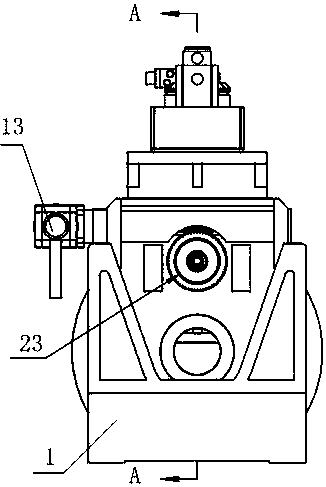

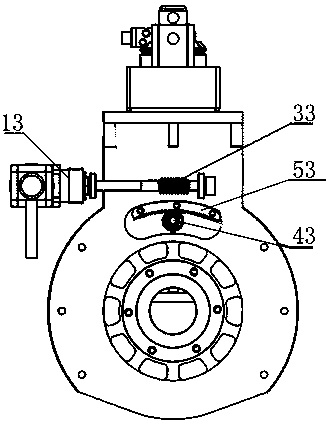

[0025] Below in conjunction with accompanying drawing, the present invention will be further described, as Figure 1-7 Shown:

[0026] A vertical gear hobbing machine, including a frame, a bracket and a column arranged on the frame, a workbench is set on the bracket for fixing and driving the rotation of the tooth blank to be processed, and a hobbing power head assembly is set on the column for To shape the gear blank, it is characterized in that: the gear hobbing power head assembly includes a gear hobbing cutter installation device, a gear hobbing turning device, and a cutter shifting device, and the gear hobbing cutter installation device includes a relay shaft assembly 7, The knife shifting spline shaft 6 is characterized in that: the relay shaft assembly 7 includes a spline sleeve fixed on the hobbing turret 3, the spline sleeve is matched with the upper section of the knife shifting spline shaft 6, and the knife shifting The lower section of the spline shaft 6 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com