Rail air pressure welding equipment and method of using the same

A technology for welding equipment and rails, which is applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of sacrificial stiffness, poor equipment stiffness, unstable welding quality, etc., and achieve improved mechanization, automation, and welding quality Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

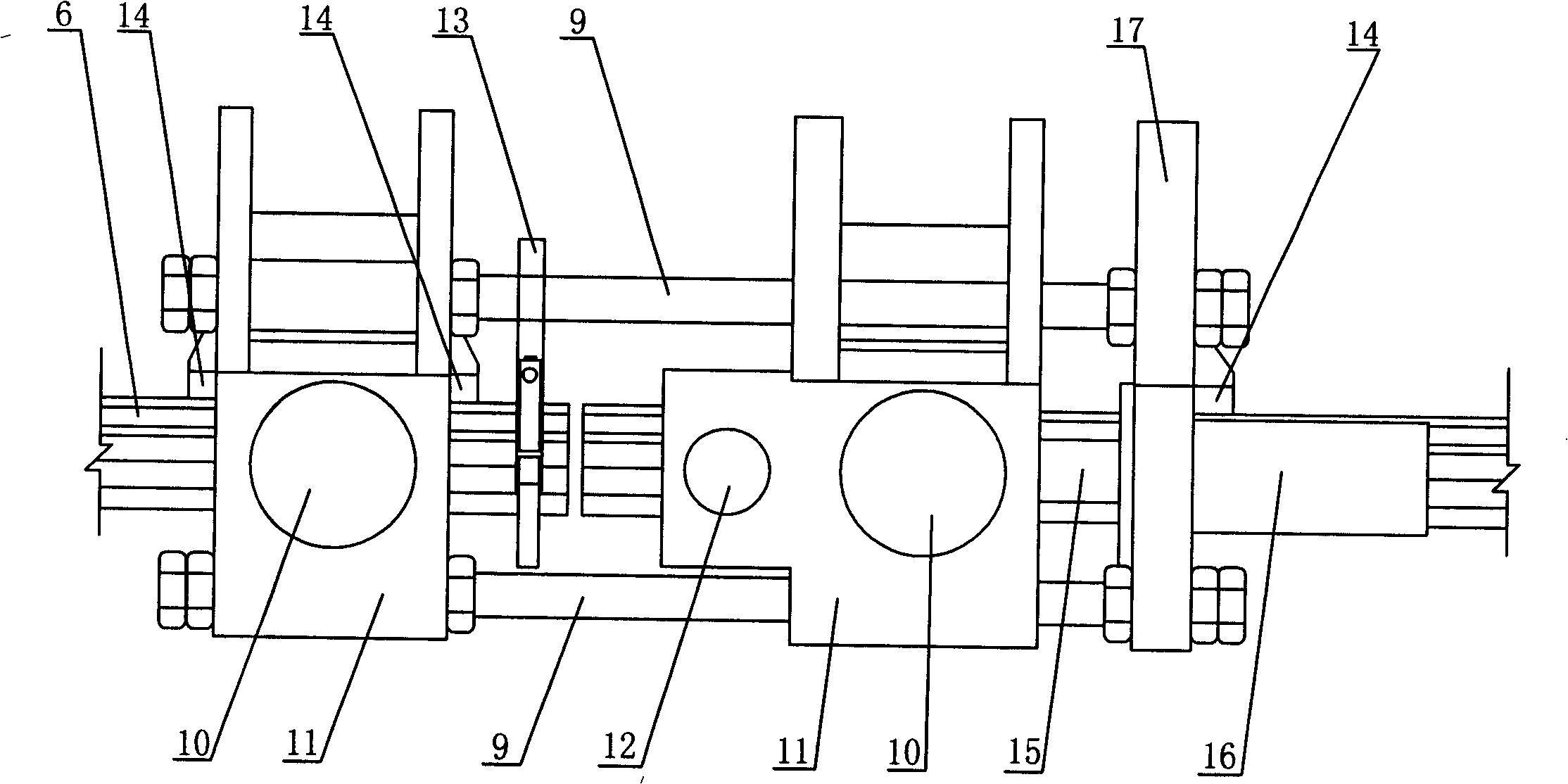

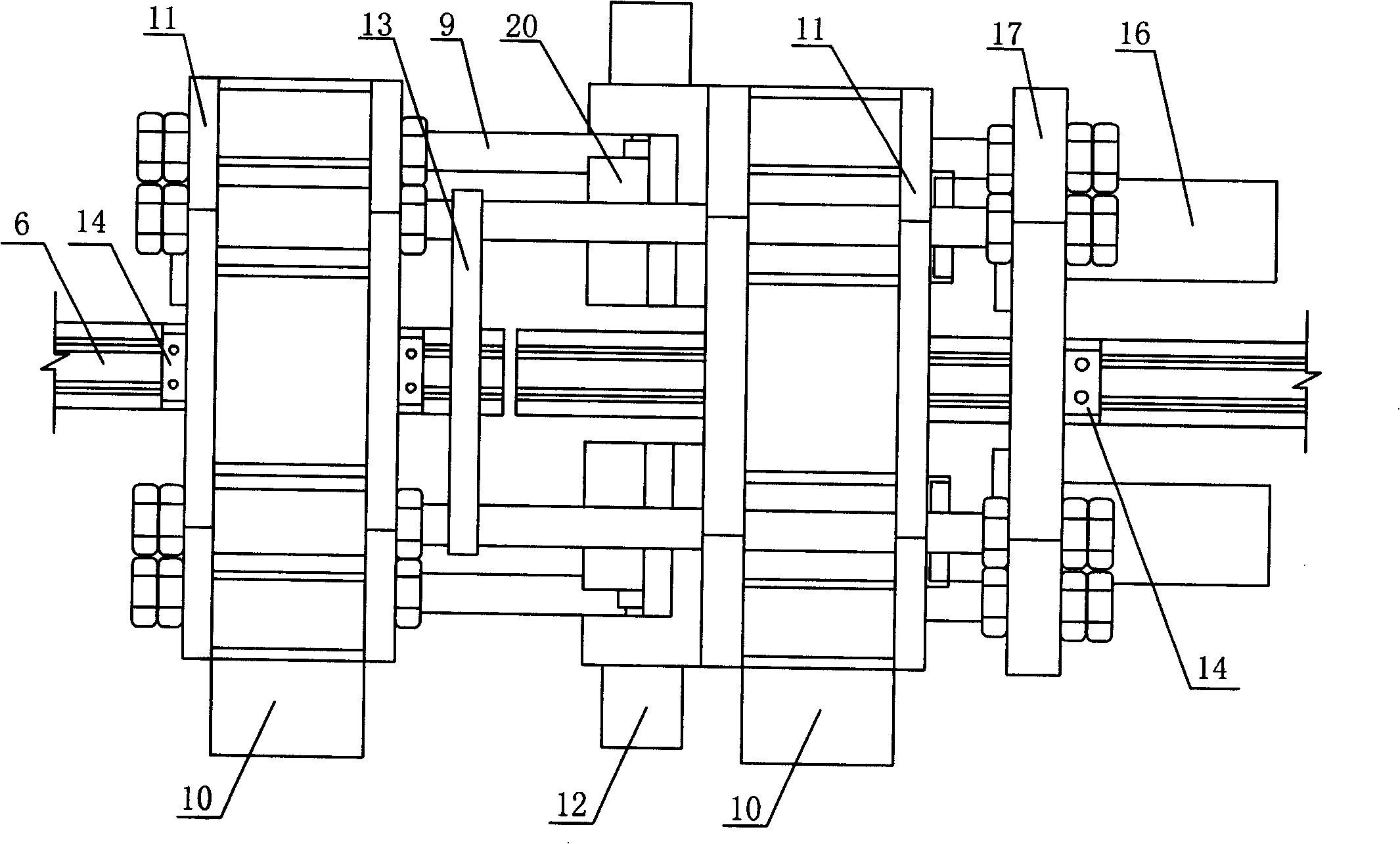

[0039] Such as figure 1 As shown, a control room, a machine head storage room 3, a generator room 4 and a material room 5 are provided on the flatbed truck 8, and the control room and the machine head storage room 3 are used to store the welding machine head 1, the control cabinet, and the hydraulic pump station and cooling pump station; the effect of generator room 4 is to store the generator, and this generator is a backup, because the rail pressure welding operation does not need a high-power generator set, so railcars can also be used to generate electricity; the effect of material room 5 is to store welding Consumables used (such as grinding wheel, grinder, jack and other auxiliary construction equipment, oxygen cylinders, acetylene cylinders, etc.). The top of the flatbed truck 8 is provided with a boom 2 that can stretch back and forth and swing left and right, and the end of the boom 2 is suspended with a welding head 1 . The front and rear expansion and contraction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com