A kind of purple light led production method containing silica gel lens and purple light led

A technology of silica gel lens and production method, which is applied in the field of violet LEDs, can solve the problems of short service life of violet LEDs, low optical power of violet LEDs, narrow application range of LEDs, etc. Good power and product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

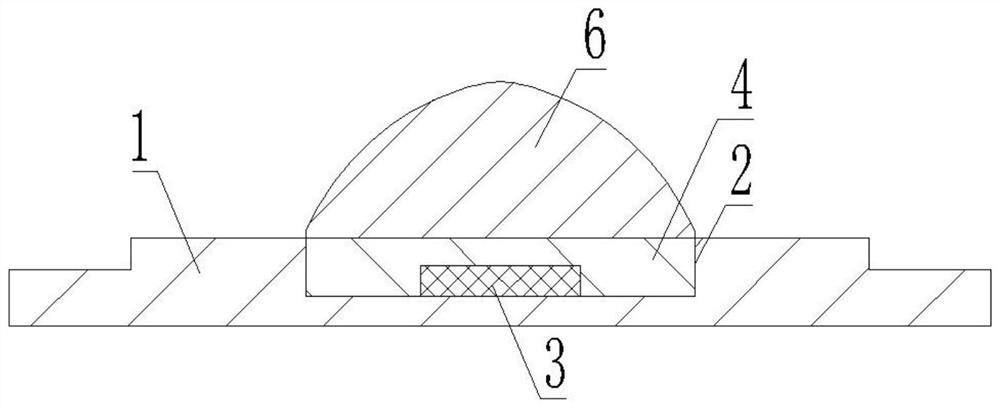

[0025] Embodiment one. A method for producing a violet LED containing a silica gel lens, comprising the following steps:

[0026] a. Put the Ziguang LED chip into the bracket bowl, and carry out crystal bonding and wire bonding on the Ziguang LED chip to obtain product A;

[0027] b. Carry out dispensing treatment on product A, use transparent silica gel to level the groove part of the bracket cup, and get product B;

[0028] c. Fasten the mold on product B (on the transparent silica gel of product B), inject transparent silica gel into the mold, use the mold top process to form a raised silicone lens, and obtain the finished product after curing.

[0029] The point level in the step b is to use a glue dispenser to point the transparent silica gel into the groove part of the bracket bowl, and make the top surface of the point-in transparent silica gel flush with the top surface of the bracket bowl cup; the mold top in step c The process is to use a mold top machine to solidi...

Embodiment 2

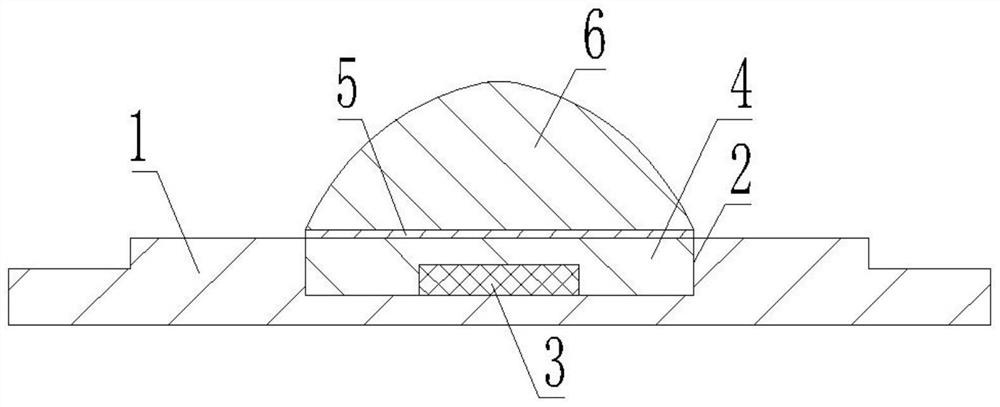

[0031] Embodiment two. A method for producing a violet LED containing a silica gel lens, characterized in that it comprises the following steps:

[0032] a. Put the Ziguang LED chip into the bracket bowl, and carry out crystal bonding and wire bonding on the Ziguang LED chip to obtain product A;

[0033] b. Carry out dispensing treatment on product A, use transparent silica gel to level the groove part of the bracket bowl, and then spray transparent adhesive on the surface of the flat transparent silicone to obtain product B;

[0034] c. Fasten the mold on product B (on the transparent adhesive of product B) (transparent adhesive is mainly used for bonding between two layers of transparent silica gel), inject transparent silica gel into the mold, and use the mold top process to form a Raised silicone lens, cured to get the finished product.

[0035] The point level in the step b is to use a glue dispenser to point the transparent silica gel into the groove part of the bracke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com