Locking and releasing device for large connecting piece

A connector and large-scale technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of fast and accurate locking and release of large connectors, and solve the problems of low assembly efficiency, obvious effect, locking and Ease of Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

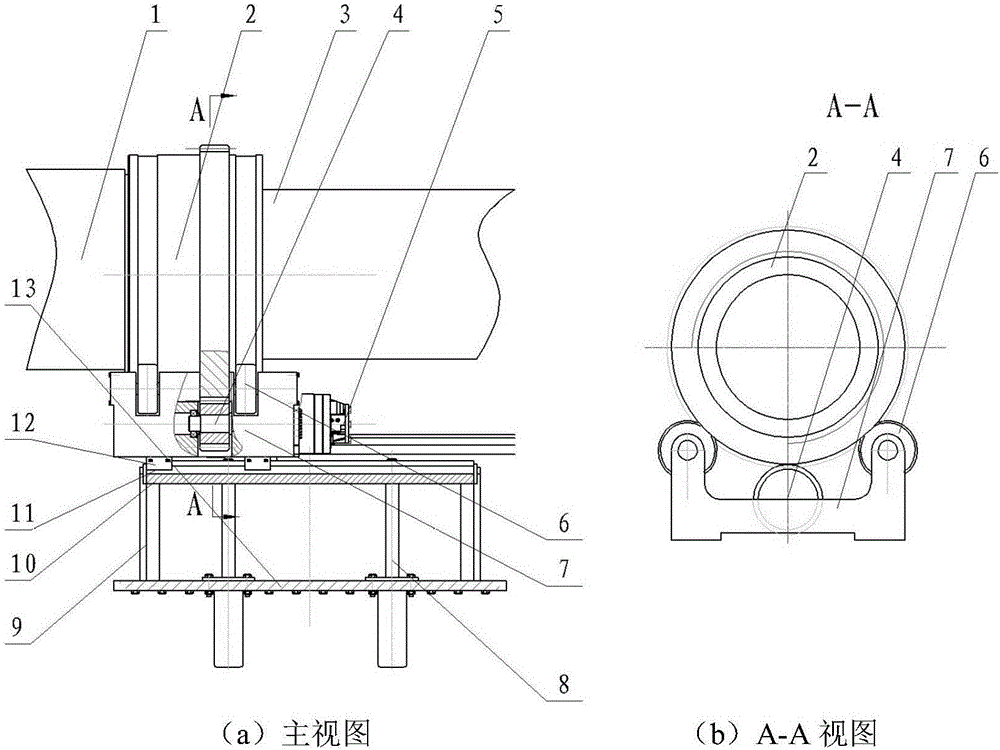

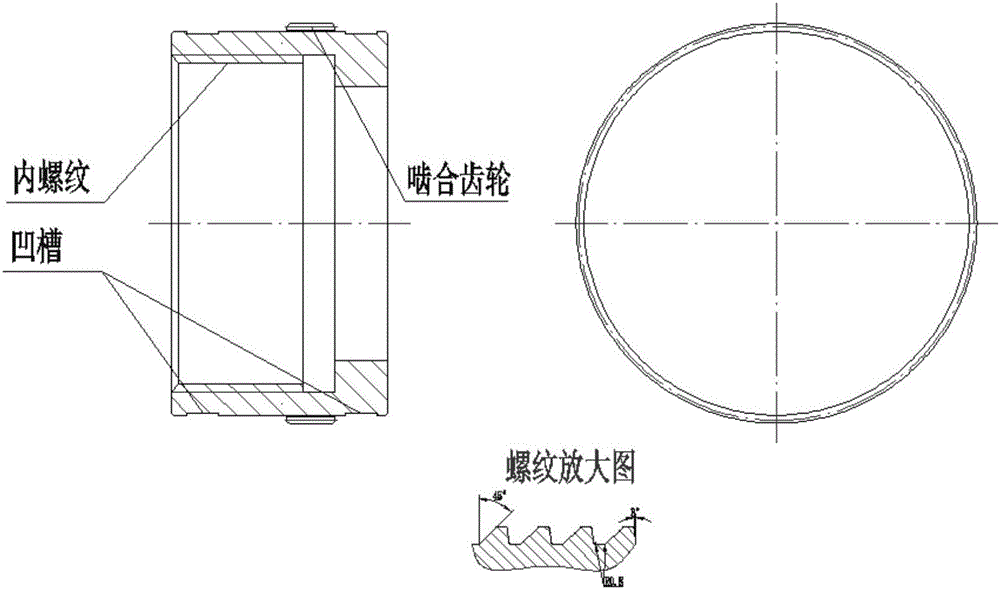

[0019] Such as figure 1 As shown, the structural composition and usage method of the present invention will be described below by taking the locking of the shaft I1 and the shaft II3 through the gear nut 2 as an example.

[0020] A device for locking and releasing large shaft parts, including drive gear 4, motor or motor 5, roller 6, bracket 7, oil cylinder 8, slide rail 9, guide rail support plate 10, guide rail 11, slider 12, base 13;

[0021] Among them, the driving gear 4 and the motor or motor 5 belong to the constant force mechanism; the roller 6 and the bracket 7 belong to the automatic centering mechanism; the oil cylinder 8, the slide rail 9 and the base 13 belong to the lifting mechanism; the guide rail support plate 10, the guide rail 11 and the slider 12 belong to free follow-up agencies.

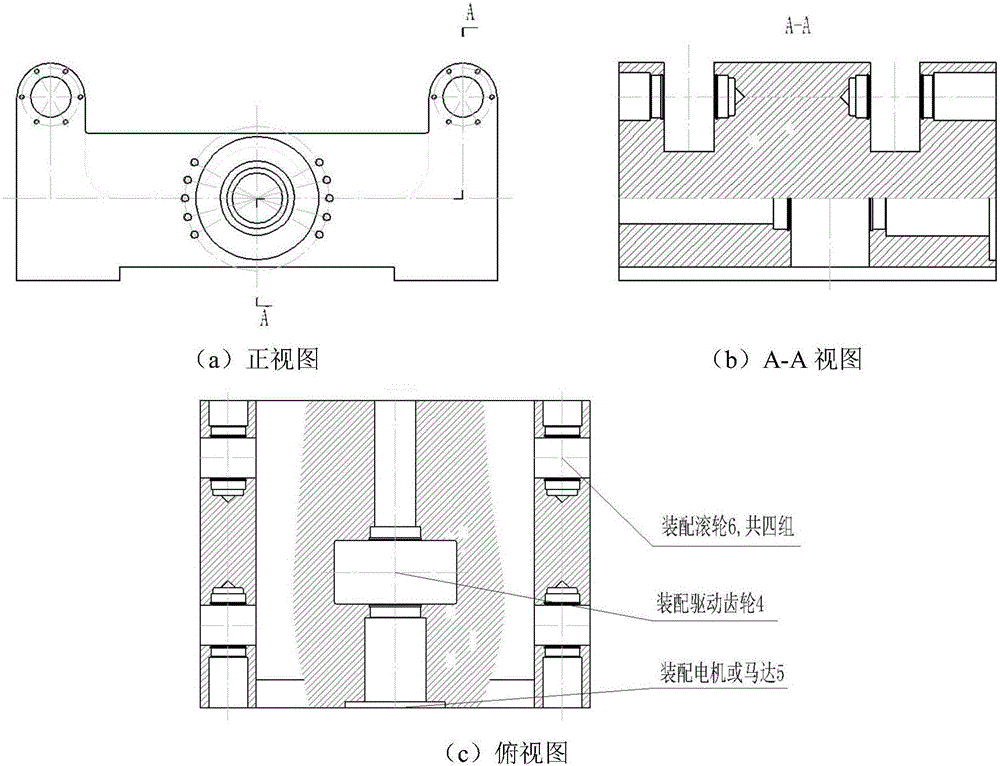

[0022] figure 2 It is a schematic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com