Assembly tool and assembly method for engine flywheel bearing

A technology for assembling tools and engines, applied in manufacturing tools, hand-held tools, etc., can solve problems such as hidden safety hazards, low assembly efficiency, and high labor intensity, and achieve the effects of improving assembly quality, convenient operation, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

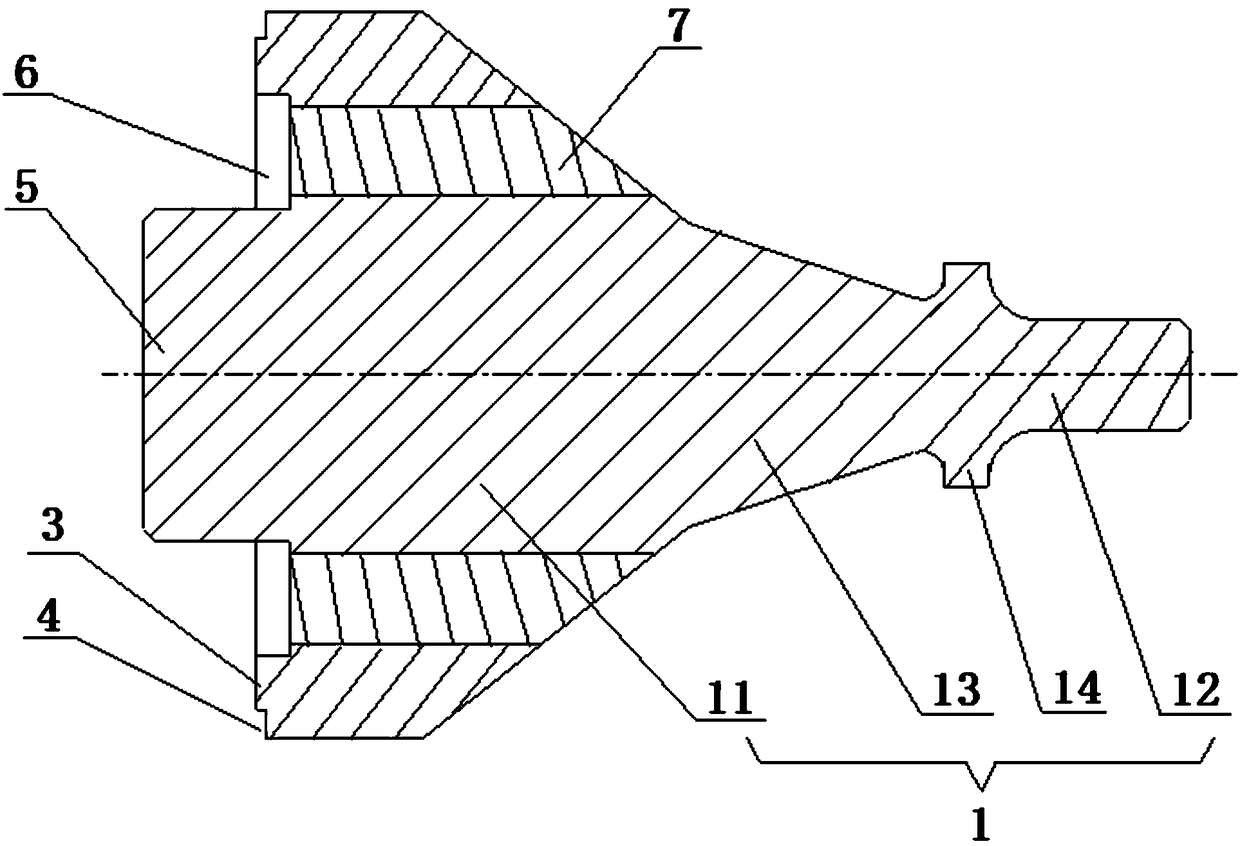

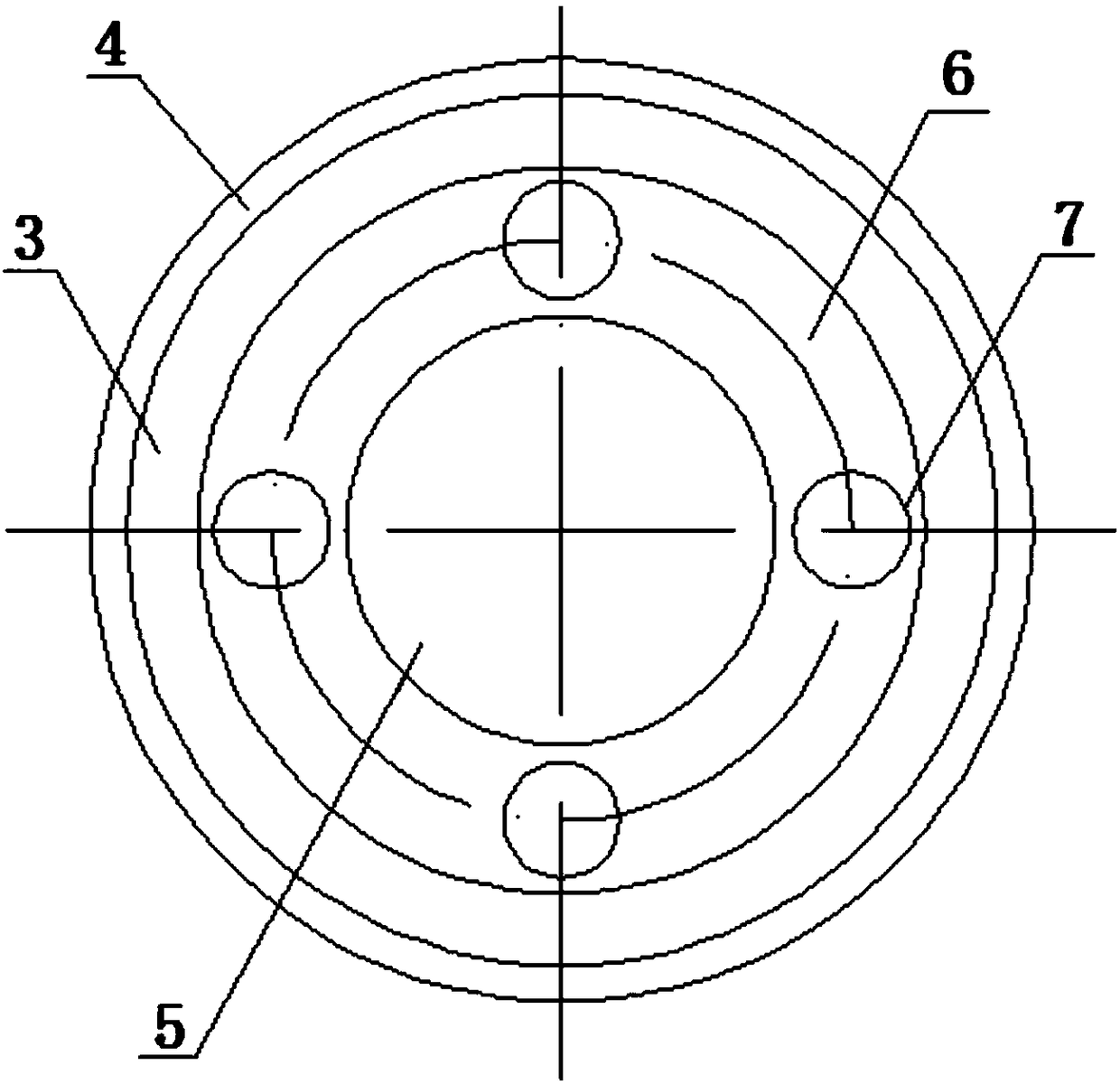

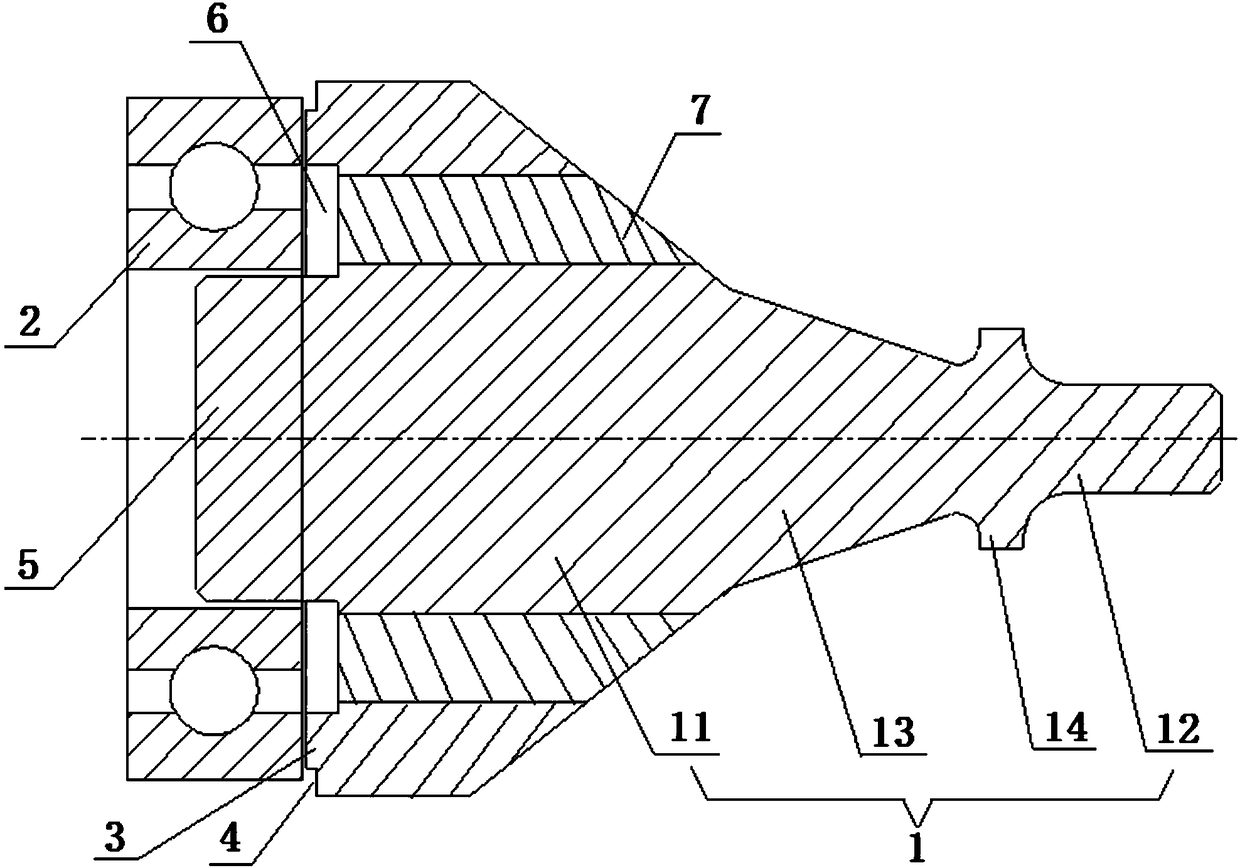

[0028] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

[0029] refer to Figure 1-4 , the assembly tool of a kind of engine flywheel bearing of the present invention comprises the beating body 1 that is used for positioning and beating bearing 2, and the end face of this beating body 1 is circular, is provided with bearing 2 on one end face of this beating body 1 The flat cylindrical reference boss 3 whose outer ring size is suitable, one end face of its bearing 2 is in contact with the end face of the reference boss 3, and a height difference between the beating body 1 and the reference boss 3 forms a preventable The ring-shaped relief groove 4 where the beating body 1 interferes with the side wall of the bearing installation hole. During the installation of the bearing 2, when one end of the bearing 2 is parallel to the end face of the bearing installation hole, the bearing 2 continues to be in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com