Manual grinding machine and using method thereof

A grinding machine and grinding disc technology, which is applied to portable grinding machines, grinding machines, ceramic molding machines, etc., can solve the problems of difficulty in ensuring accuracy and shape, difficulty in grinding, and easy damage to cement boards by large grinding machines, and achieve simple structure, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

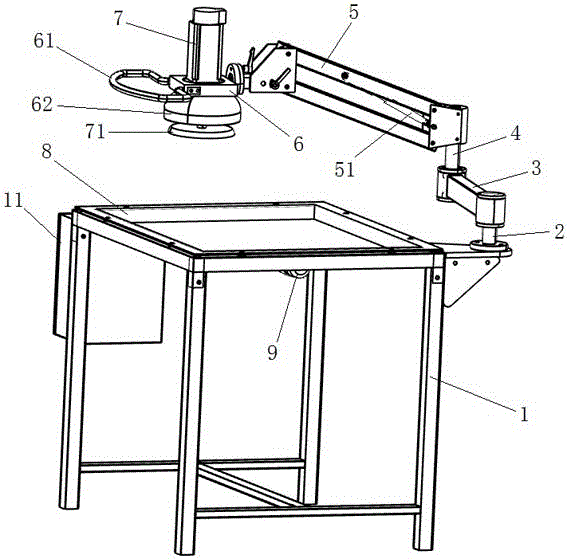

[0015] Embodiment one: if figure 1 As shown, a manual grinding machine includes an operating table 1, a vertical shaft 2 is arranged on one side of the operating table 1, and a horizontal bar 3 that can rotate around the shaft is hinged on the upper part of the vertical shaft 2, and the other end of the horizontal bar A vertical rod 4 is hinged, the upper end of the vertical rod 4 is hinged with a connecting rod 5 that can rotate up and down, and a gas spring 51 is also hinged between the vertical rod 4 and the middle part of the connecting rod 5 (the gas spring keeps the grinding disc in the air all the time. state, the control handle must be pressed down to work), the other end of the connecting rod is hinged with a support plate 6, the upper part of the support plate is provided with a motor 7, and the output end of the motor passes through the support plate and is provided with a grinding disc 71. A mud pump 9 is provided at the bottom of the operating platform.

[0016] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com