Machine core of electric pencil sharpening machine

A pencil sharpening and electric technology, applied in sharpening devices, printing, office supplies, etc., can solve the safety problems of electric pencil sharpeners, easy to hurt users, etc., and achieve the effect of preventing false start and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

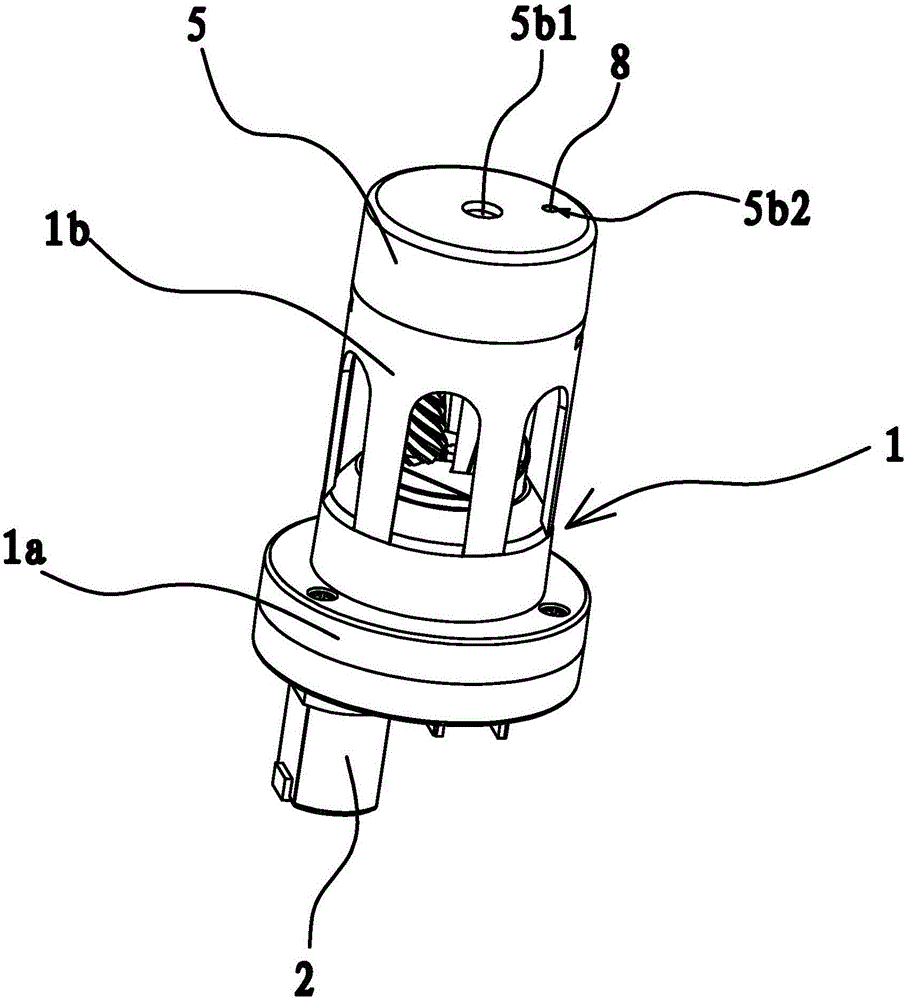

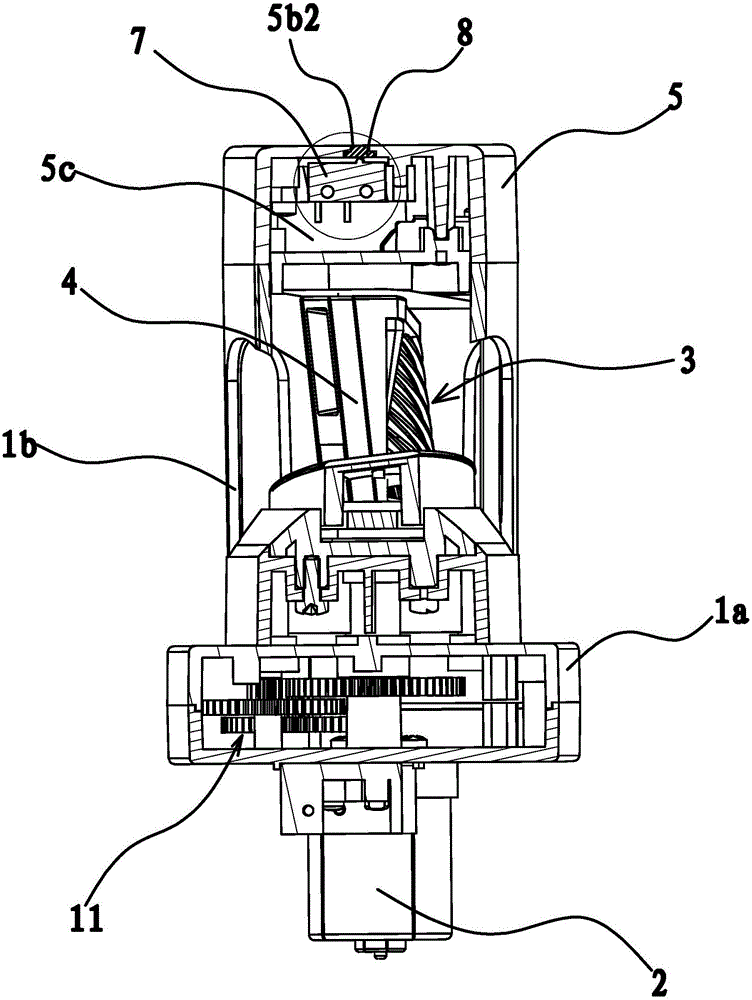

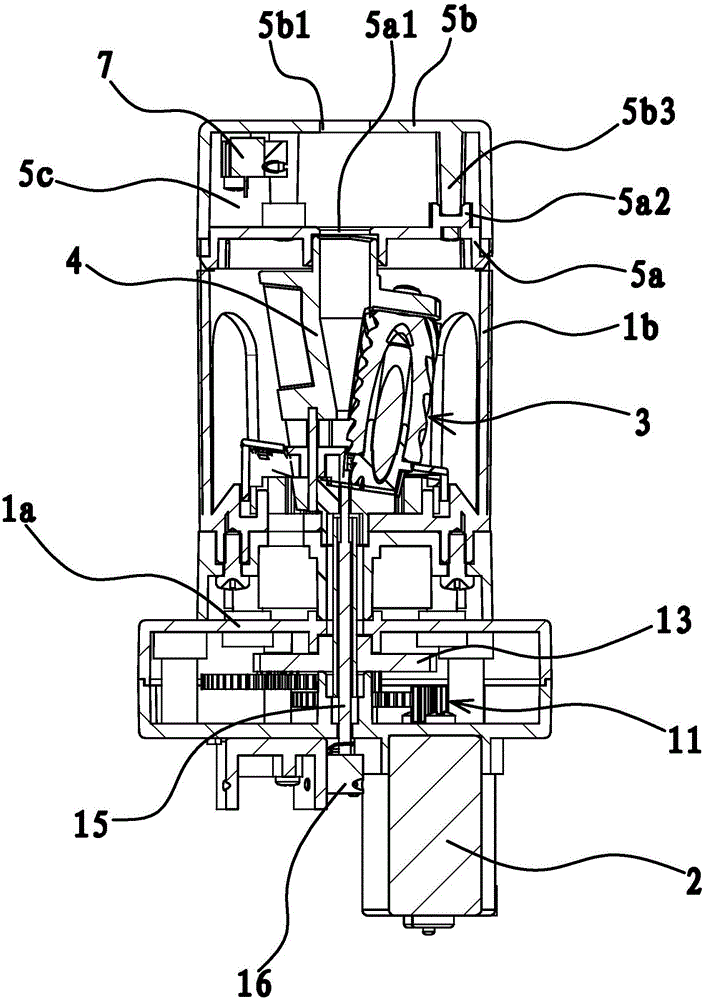

[0042] Such as figure 1 , figure 2 and image 3 As shown, a movement of an electric pencil sharpener includes a housing 1 with an open upper end, a pen holder 4 disposed in the housing 1 , a planer assembly 3 and a motor 2 located on one side of the pencil holder 4 . The upper end of the housing 1 is connected with a protective cover 5. The protective cover 5 includes a bottom plate 5a and a cover body 5b. There are several bayonet holes on the outer side of the upper end of the housing 1. The bottom edge of the bottom plate 5a has a corresponding number of blocks. The mouth is matched with the upper end of the housing 1 to form a buckle connection. The inner top of the cover body 5b has a protruding connecting column 5b3, and the bottom plate 5a has a connecting head 3b. The connecting column 5b3 is against the positioning head 5a2. The connection is made by fasteners that pass from the bottom of the base plate 5a through the positioning head 5a2 and into the connection po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com