Tire bead structure

A bead and tire technology, applied to tire parts, bead, transportation and packaging, etc., can solve the problems of low friction, poor grip at the bottom of tire bead 33, strong strength, etc., to increase friction and improve The effect of grasping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

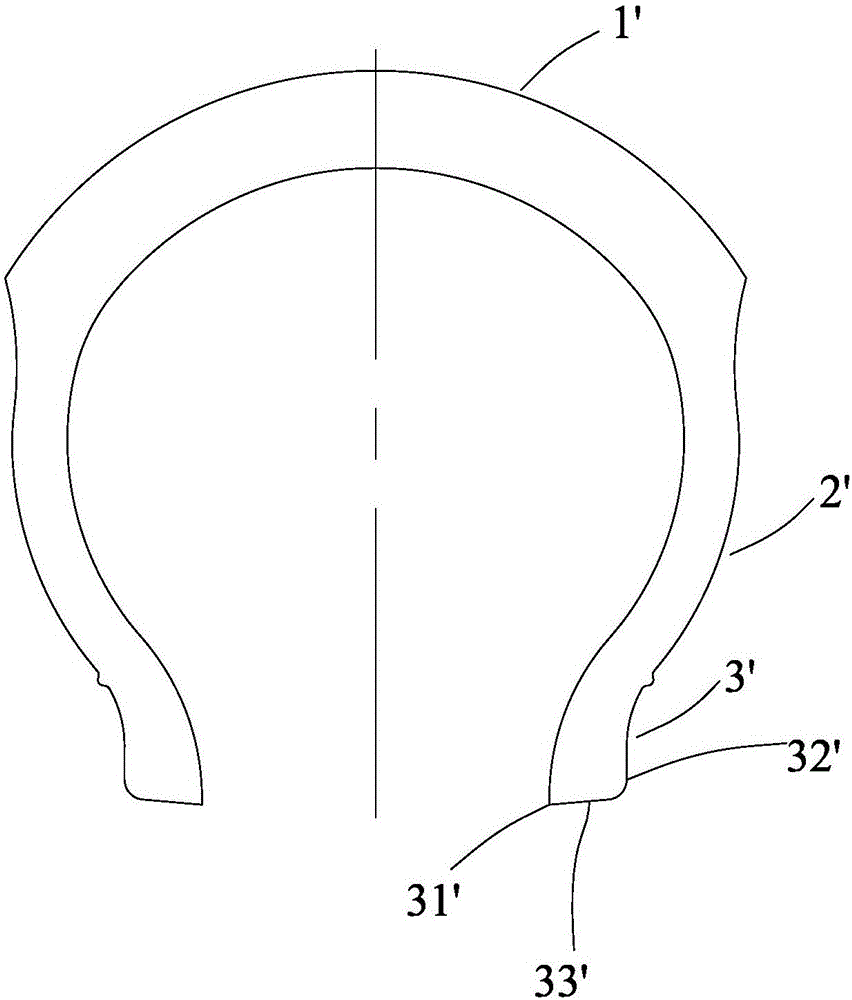

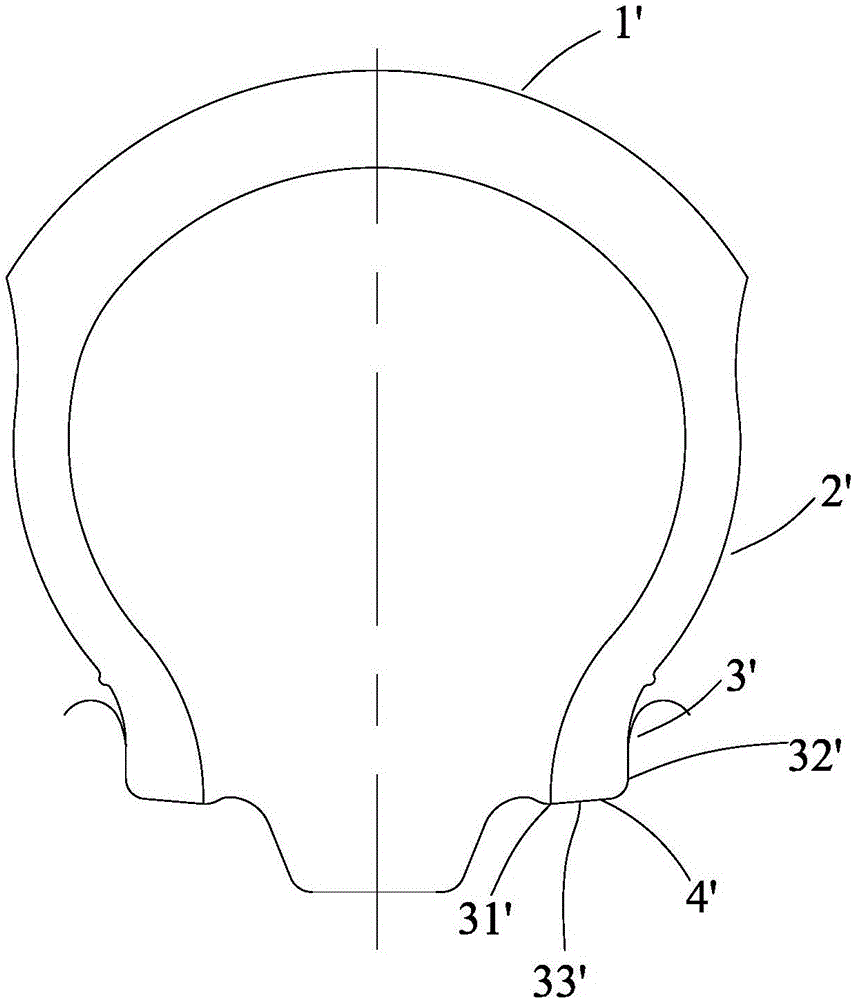

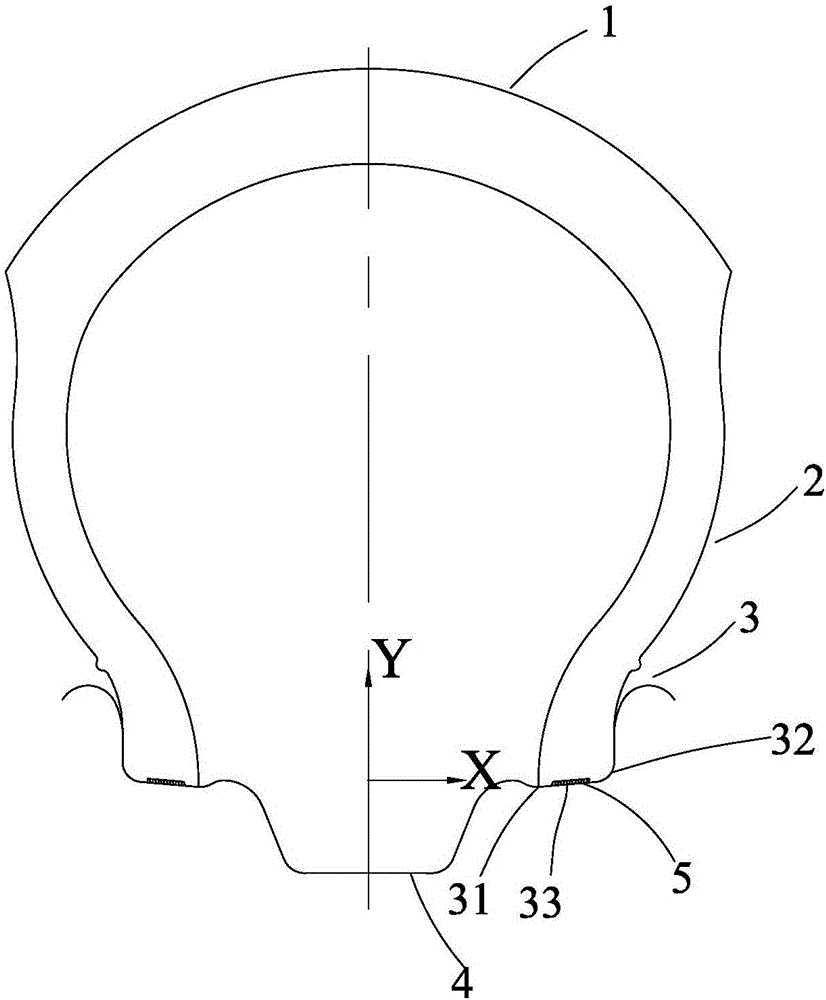

[0032] like Figure 3 to Figure 11 As shown, the present invention discloses a tire bead structure, the X-axis is the tire axial direction, and the Y-axis is the tire radial direction. The tire includes a tread portion 1, two sidewall portions 2 and two bead portions 3, wherein each tire The outer edge of the bead in the lip 3 that cooperates with the rim bead seat 4 includes the bead toe 31 , the bead heel 32 and the bead bottom 33 , in order to improve the frictional force between the bead bottom 33 and the rim bead seat 4 , promote the grip performance of tire bead bottom 33, the key of the present invention is:

[0033] A plurality of concave-convex portions 5 are equally spaced around the entire circumference of the bead bottom 33 , and each concave-convex portion 5 consists of several convex portions 51 and concave portions 52 arranged at intervals in the axial direction.

[0034] Each convex portion 51 forms a trapezoidal convex portion that is wider at the top and nar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com