Design method of low-noise propeller of aircraft and propeller configuration

A design method and propeller technology, applied in the field of aircraft, can solve problems such as unsatisfactory aerodynamic and noise characteristics, and achieve the effects of improving flight experience, optimizing flight performance, and reducing noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

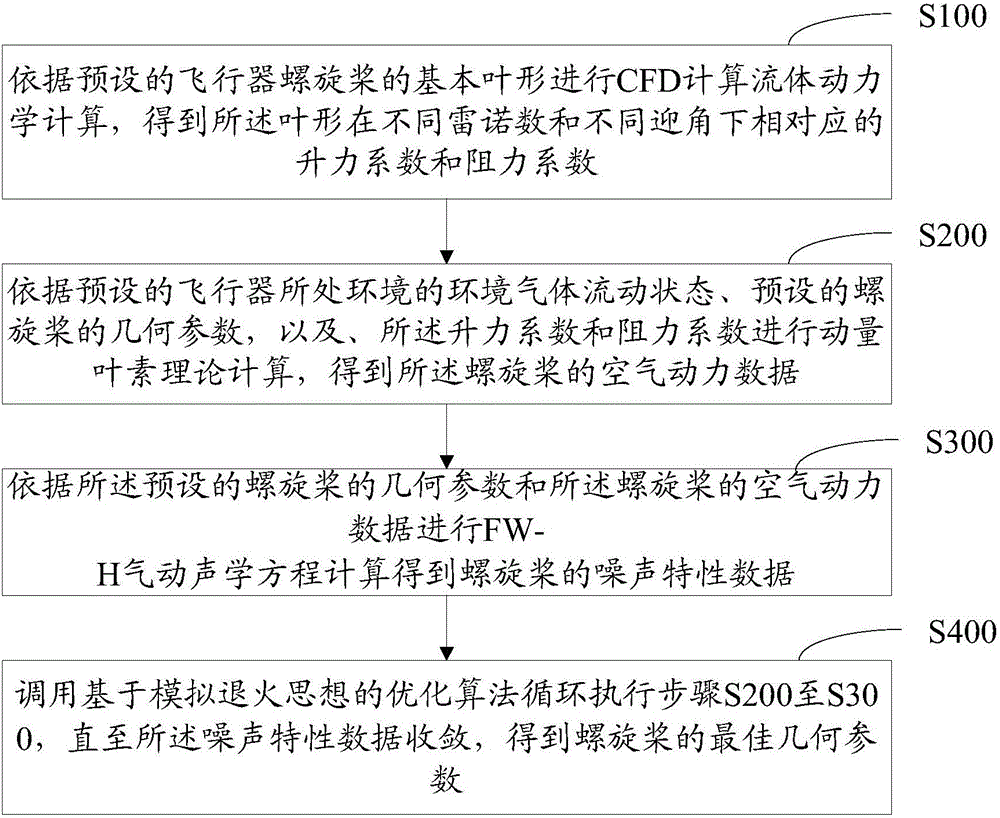

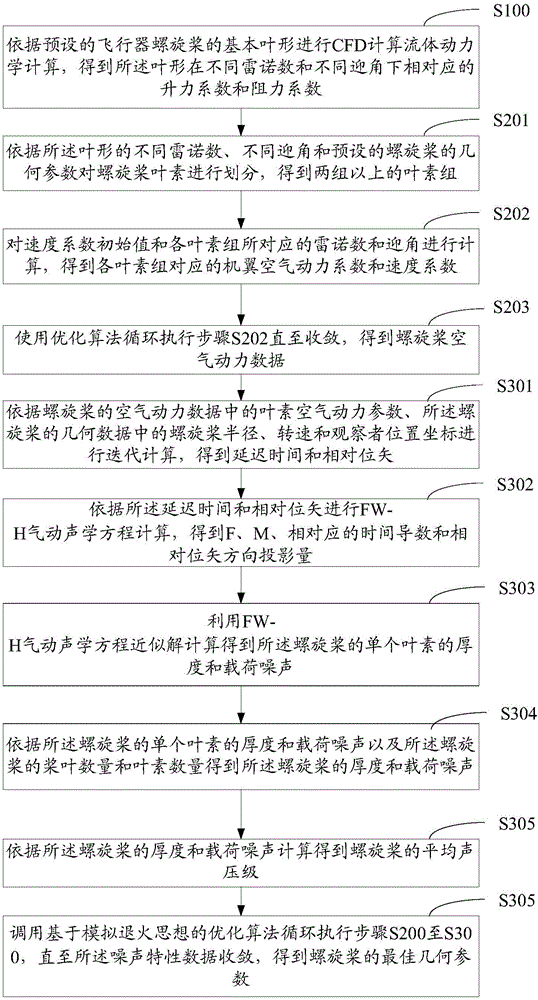

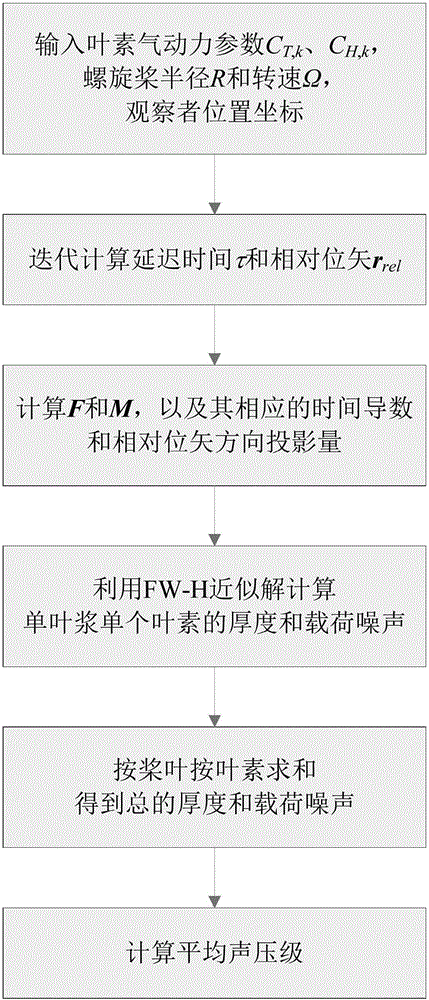

[0054] Please refer to figure 2 and image 3 , Embodiment 1 of the present invention is:

[0055] S100: Perform CFD computational fluid dynamics calculation according to the preset basic blade shape of the aircraft propeller, and obtain the corresponding lift coefficient and drag coefficient of the blade shape under different Reynolds numbers and different angles of attack;

[0056] Obtain the calculation basis by presetting the basic blade shape of the aircraft propeller;

[0057] S101: Express the corresponding lift coefficient and drag coefficient of the blade shape under different Reynolds numbers and different angles of attack in a tabular form.

[0058] S200: Perform theoretical calculation of momentum blade elements according to the preset ambient gas flow state, the preset propeller geometric parameters, and the lift coefficient and drag coefficient, to obtain the aerodynamic data of the propeller;

[0059] The preset ambient gas flow state refers to the preset env...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com