Elevator operation control method and system based on vibrating sensor and elevator

A vibration sensor and elevator operation technology, which is applied in the elevator operation control based on the vibration sensor, and in the field of elevators, can solve problems such as unsatisfactory elevator control methods, no one getting on the elevator, and prolonging the time for people in the elevator to improve. The effects of using satisfaction, improving ride experience, and reducing ride time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

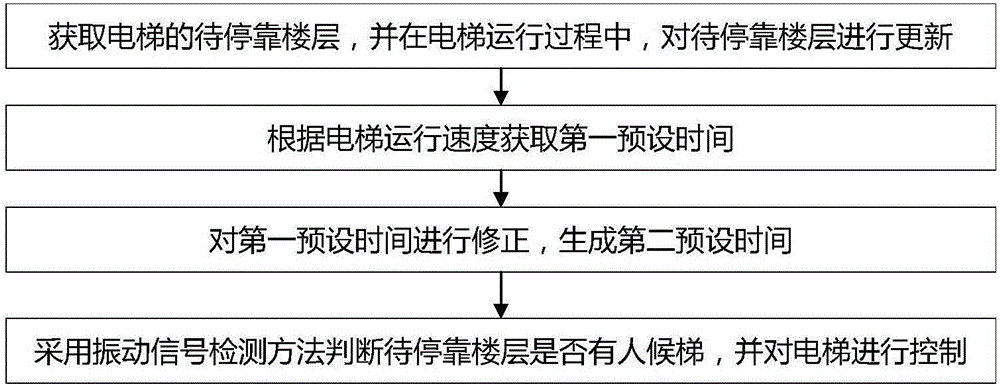

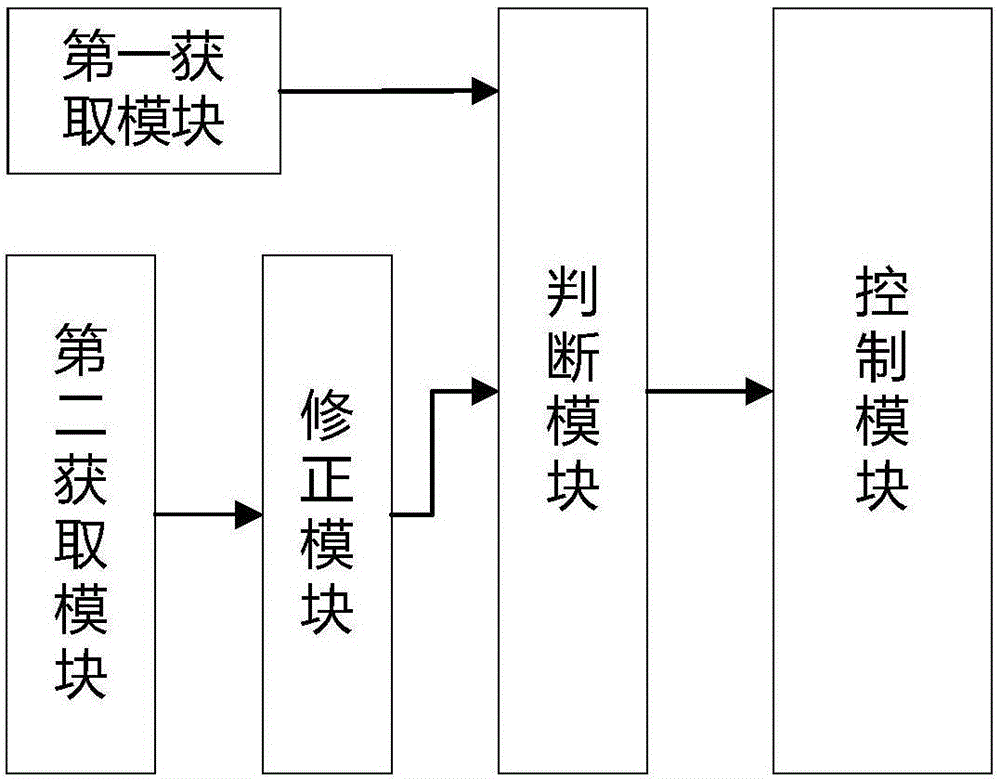

[0035] Such as figure 1 As shown, it is a schematic flow chart of a vibration sensor-based elevator operation control method in Embodiment 1, including the following steps:

[0036] Step 1, obtain the floor to be stopped by the elevator, and update the floor to be stopped according to the preset frequency during the operation of the elevator; the floor to be stopped is a floor where there are only signals for entering the elevator and no signals for exiting the elevator; in this embodiment , the floor to be docked is updated every 7s.

[0037] Step 2, collect the running speed of the elevator, and obtain the first preset time according to the running speed of the elevator;

[0038] Step 3, obtaining the time requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com