Perforating installing and positioning device and method for large member

A large component, installation and positioning technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of inability to disassemble the positioning device, poor effect, etc., to achieve the effect of convenient installation and operation on site, ensuring construction safety, and light volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

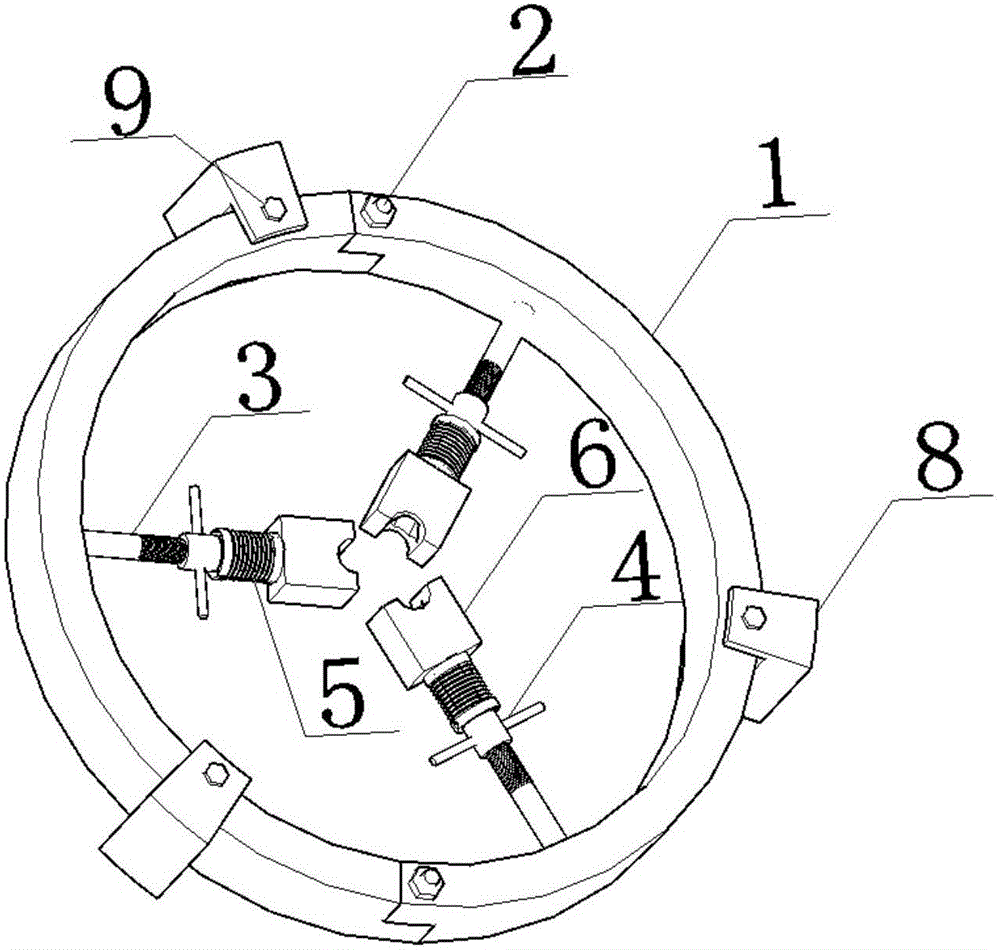

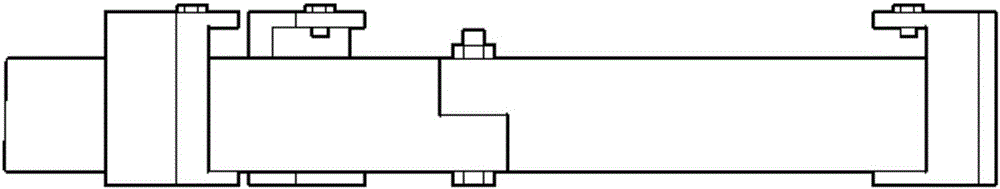

[0044] Embodiment 1: A positioning device for perforating and installing a large component, its structure is as follows Figure 1-7 shown, including:

[0045] The outer ring 1 of the detachable structure connected by bolts 2;

[0046] The inner side of the outer ring 1 is fixedly connected with one end of a guide rod 3;

[0047] A sleeve 4 and a nut 7 are installed on the guide rod 3 through a threaded pair, and the nut 7 is engaged in the alignment part 6. The alignment part 6 is preferably a horseshoe-shaped structure with a positioning groove in the middle;

[0048] An elastic component 5 is sleeved on the guide rod 3 , and the two ends of the elastic component 5 are pressed against the washer 10 . The outer washer 10 is pressed against the sleeve 4 and the inner washer 10 is pressed against the counter part 6 .

[0049] The alignment component 6 has a hexagonal hole and a flange 11, and the hole inside the flange 11 has an aperture greater than the diameter of the guide...

Embodiment 2

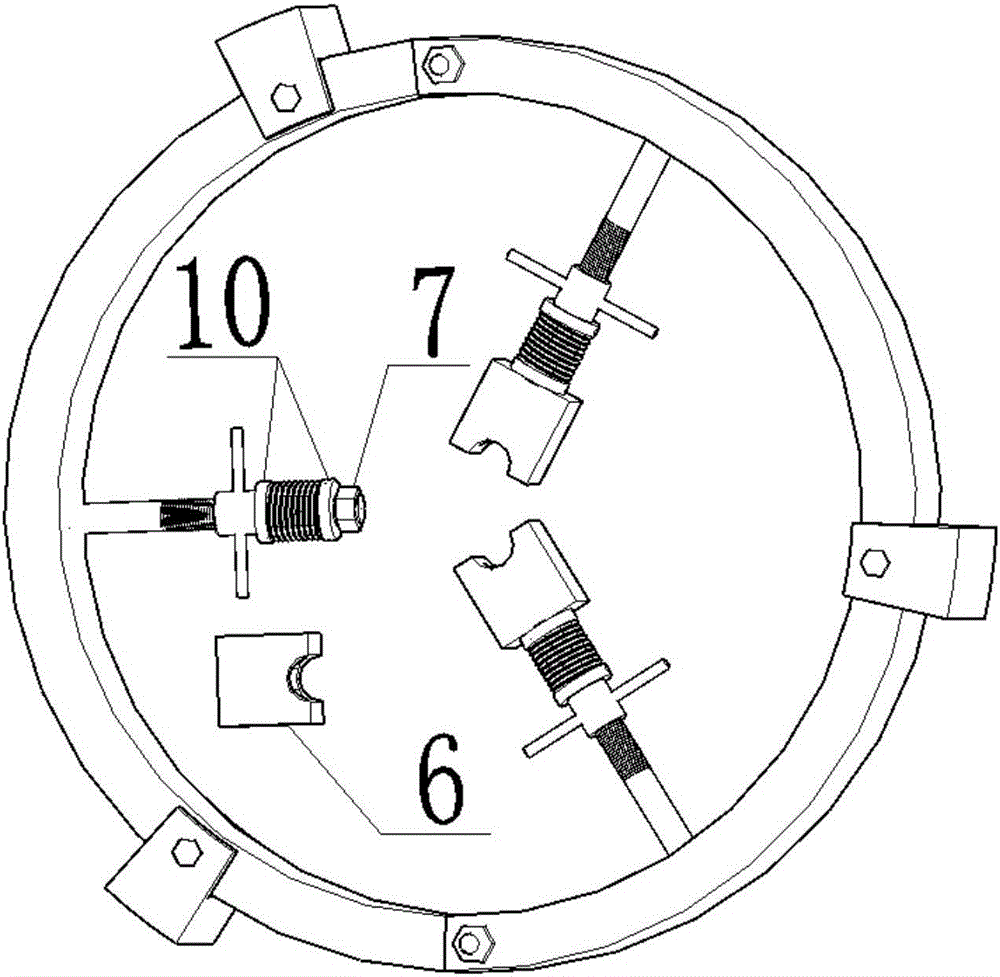

[0063] Embodiment 2: A positioning device for perforating a large component, including:

[0064] The outer ring 1 of the detachable structure connected by bolts 2;

[0065]The inner side of the outer ring 1 is fixedly connected with one end of a guide rod 3;

[0066] The guide rod 3 is a polished rod structure, and the rod body has a plurality of positioning holes perpendicular to the axis of the guide rod 3. The guide rod 3 is covered with a sleeve 4, and a positioning pin is inserted in one of the positioning holes to prevent the sleeve 4 from moving along the axis of the guide rod 3. The guide rod 3 moves in the direction of the outer ring 1.

[0067] Wherein, the front end of the guide rod is threaded, and a nut 7 is installed on the threaded part, and the nut 7 is engaged in the aligning part 6. The aligning part 6 is preferably a horseshoe-shaped structure with a positioning groove in the middle.

[0068] An elastic component 5 is sleeved on the guide rod 3 , and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com