Efficient pipeline flocculating mixer and dosing and stirring device

A pipeline flocculation and mixer technology, applied in chemical instruments and methods, special treatment targets, water/sludge/sewage treatment, etc., can solve the problems of blade deformation and breakage, unstable operation, unevenness, etc., and reduce the sealing performance. requirements, stable and uniform stirring, easy and uniform stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

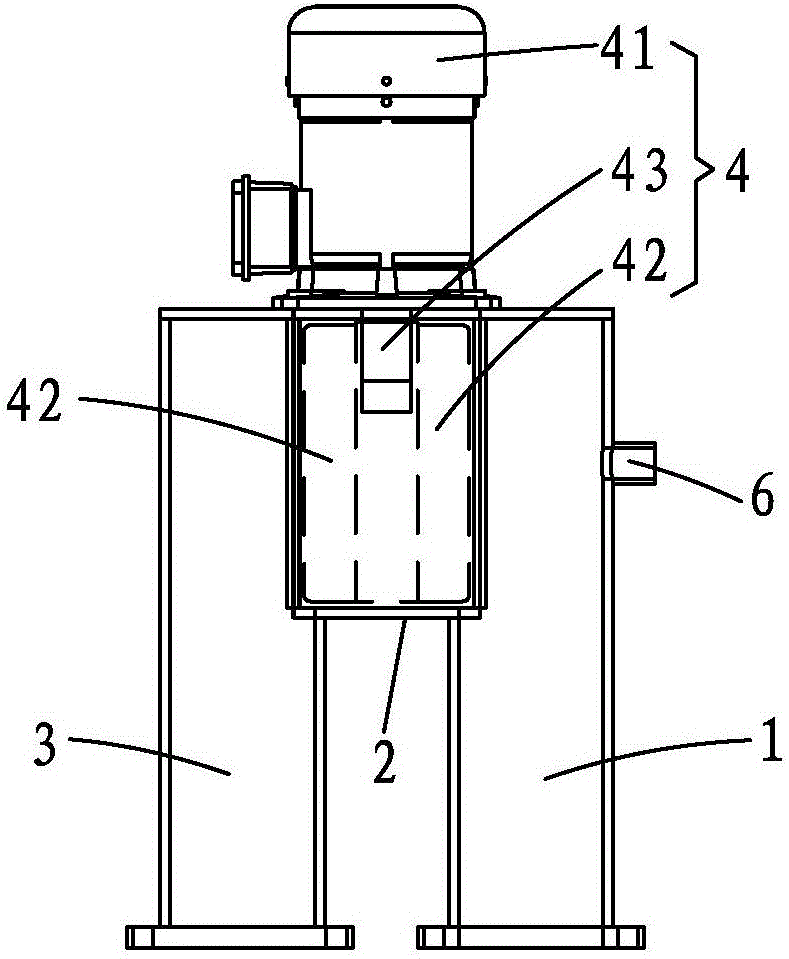

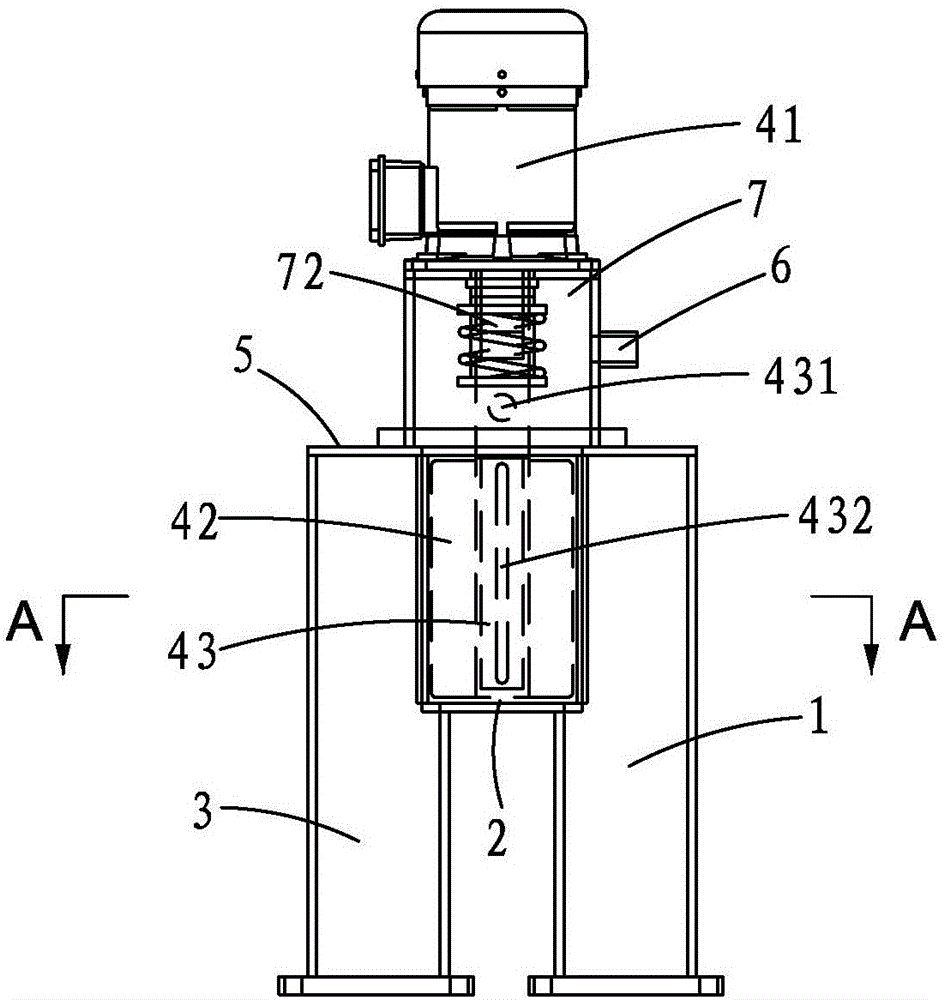

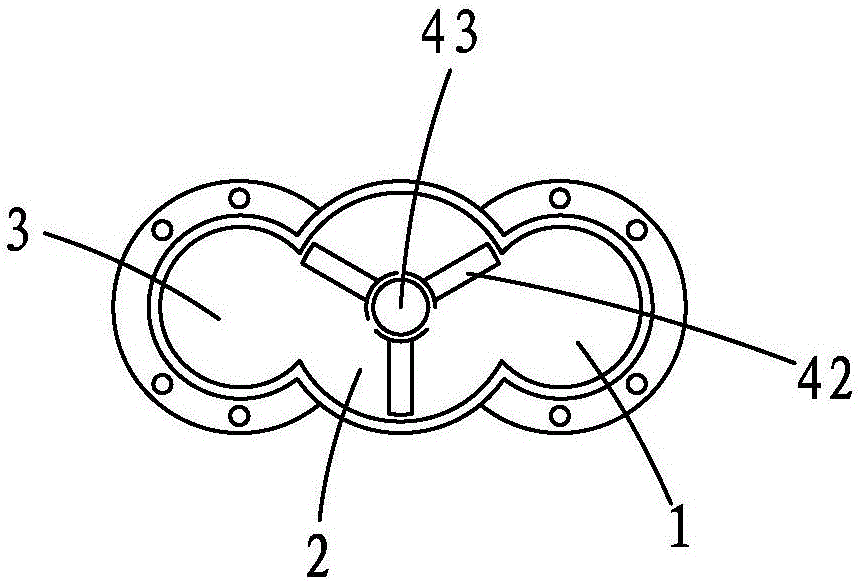

[0032] Such as Figure 1 to Figure 4 As shown, the high-efficiency pipeline flocculation mixer of the present invention includes a feed pipe 1, a stirring pipe 2, a discharge pipe 3 and an agitator 4, and the feed pipe 1, the stirring pipe 2, and the discharge pipe 3 are arranged in parallel and sequentially connected;

[0033] The stirring tube 2 is a round tube with blind ends at both ends, so that the stirring can be carried out in a relatively closed and narrow cavity, so that there is no blind area for stirring. The end of the feed pipe 1 opposite to the feed port is a blind end, and the end of the discharge pipe 2 opposite to the discharge port is a blind end. And the blind end of the feed pipe 1 and the blind end of the discharge pipe 3 are flush with a blind end of the stirring tube 2 , for example, they can be sealed by the same sealing plate 5 .

[0034] Such as image 3 and Figure 4 As shown, the side walls of the feed pipe 1 and the discharge pipe 3 are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com