Stirring system of flotation machine

A stirring system and flotation machine technology, applied in flotation, solid separation, etc., to achieve the effects of increasing mineralization probability, preventing turning over, and reducing operating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

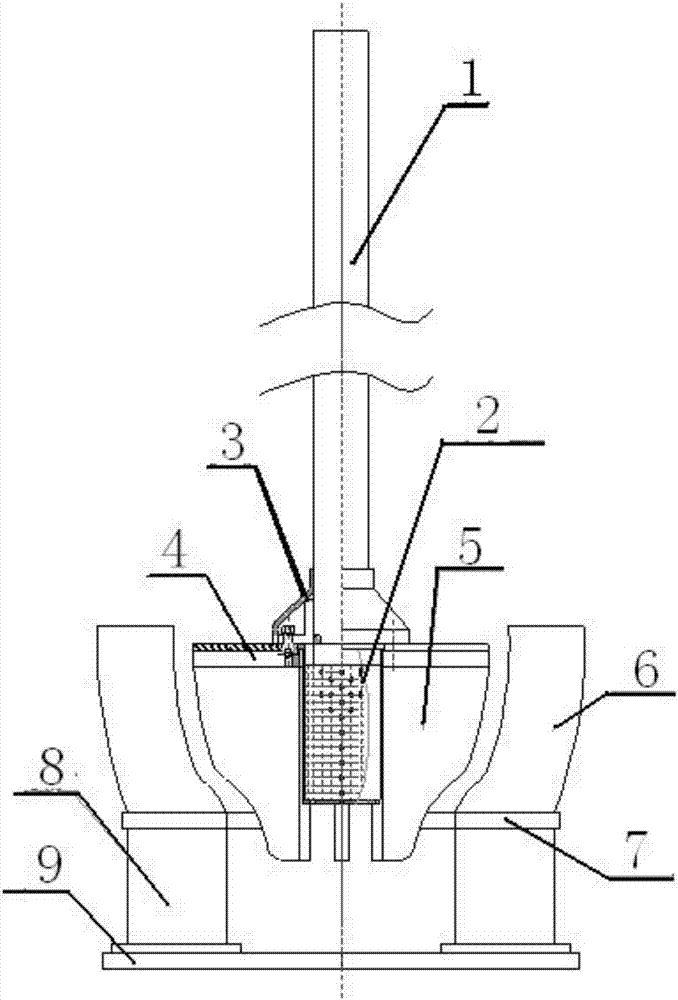

[0029] The structure and implementation process of the stirring system of the flotation machine of the present invention will be described in detail below with reference to the accompanying drawings.

[0030] Such as figure 1 As shown, this embodiment belongs to a stirring system of a flotation machine, including a main shaft 1, an air distributor 2, a rubber seal 3, an impeller and a stator, etc. The structure is the structure existing in the existing mixing system, and will not be described in detail here. The focus of the present invention-the impeller and the stator are described below.

[0031] Such as figure 1 As shown, the impeller of the agitation system of the flotation machine of the present embodiment comprises: a skeleton disc 4, which is in the shape of an annular disc, and the transverse and longitudinal directions of the skeleton disc 4 are in the form of flat straight lines, forming a rectangular cut surface, and the skeleton circle The inner ring of the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com