A quartz glass bulb automatic flame polishing device

A flame polishing and quartz technology, applied in glass production and other directions, can solve the problems of inability to immediately carry out product, polishing, and inability to guarantee product polishing, and achieve the effect of ensuring the uniformity of polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the specific implementation and working principle of the quartz glass bulb automatic flame polishing device proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. illustrate.

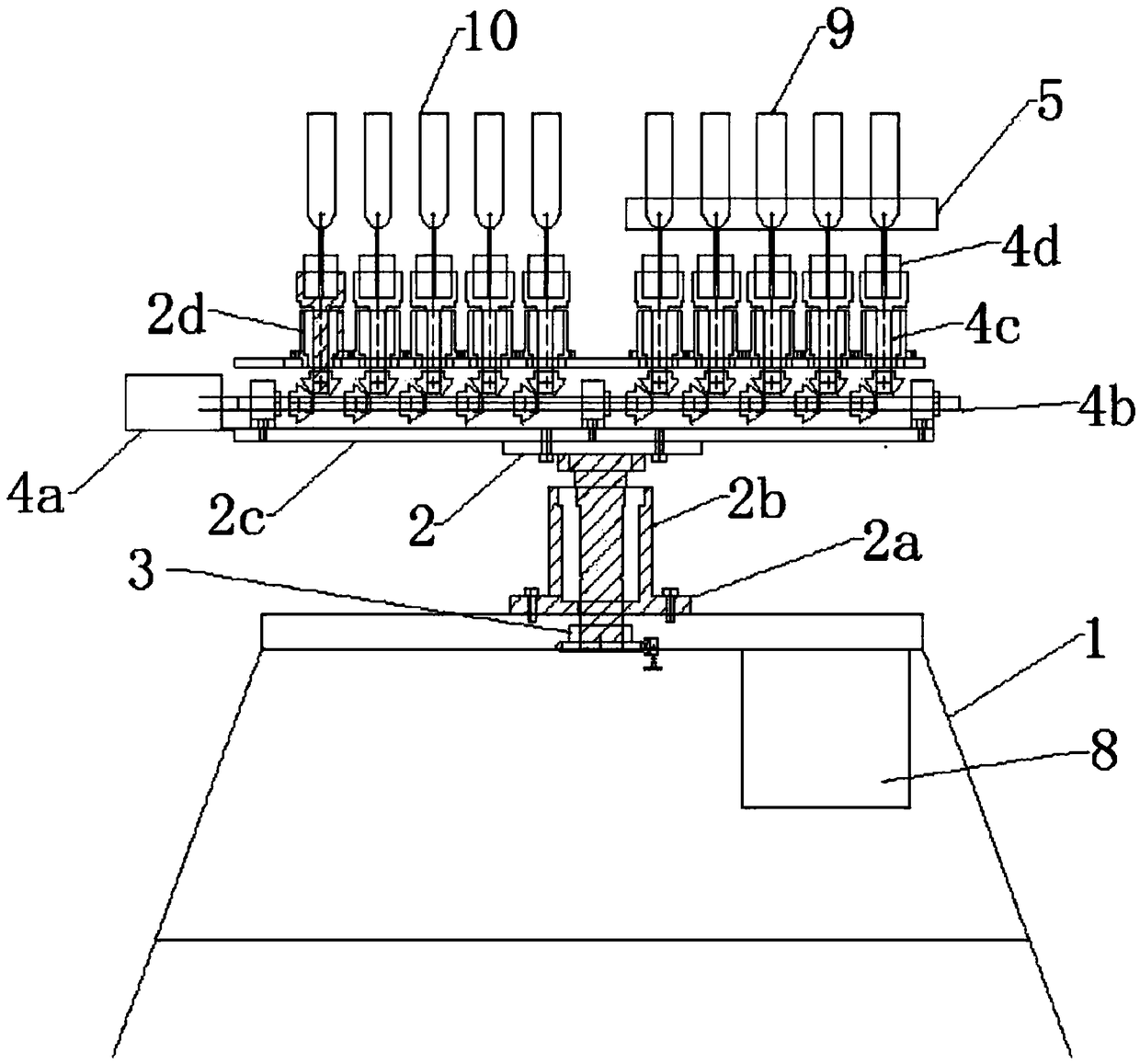

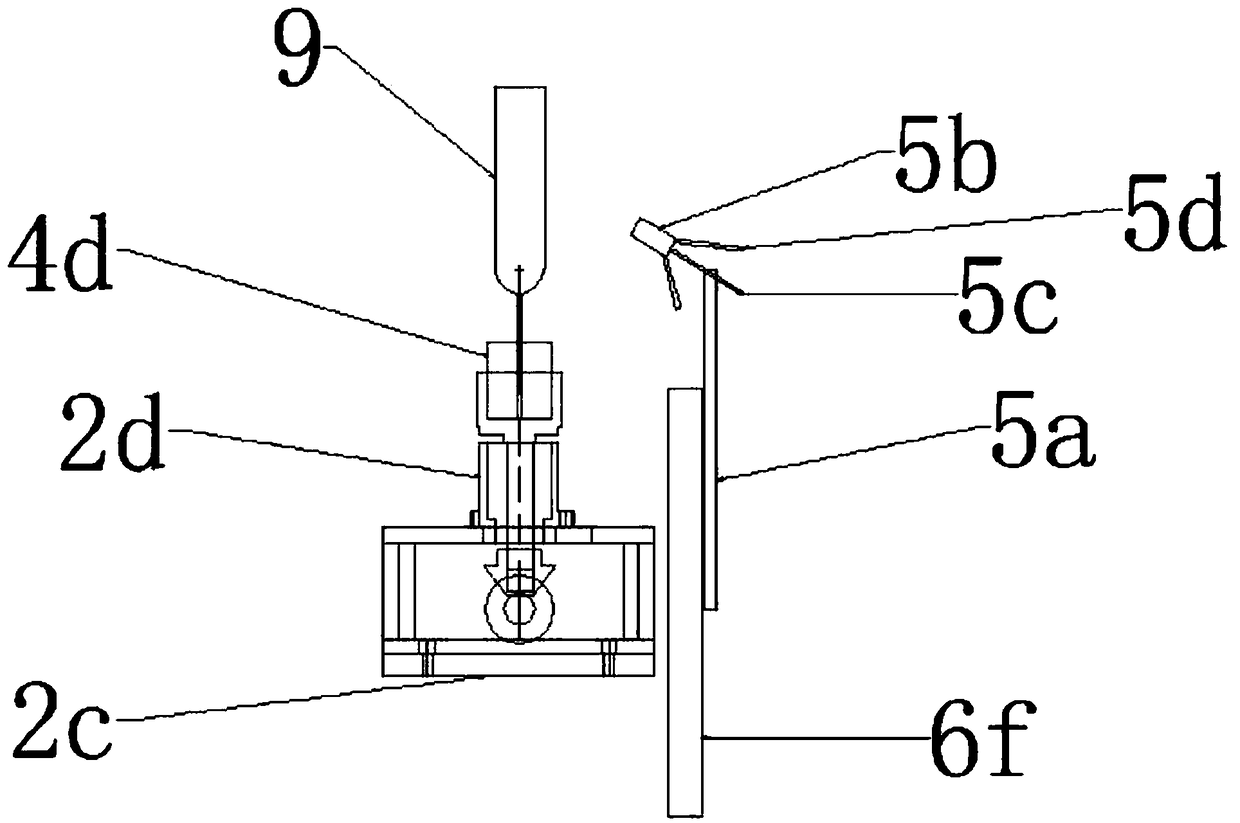

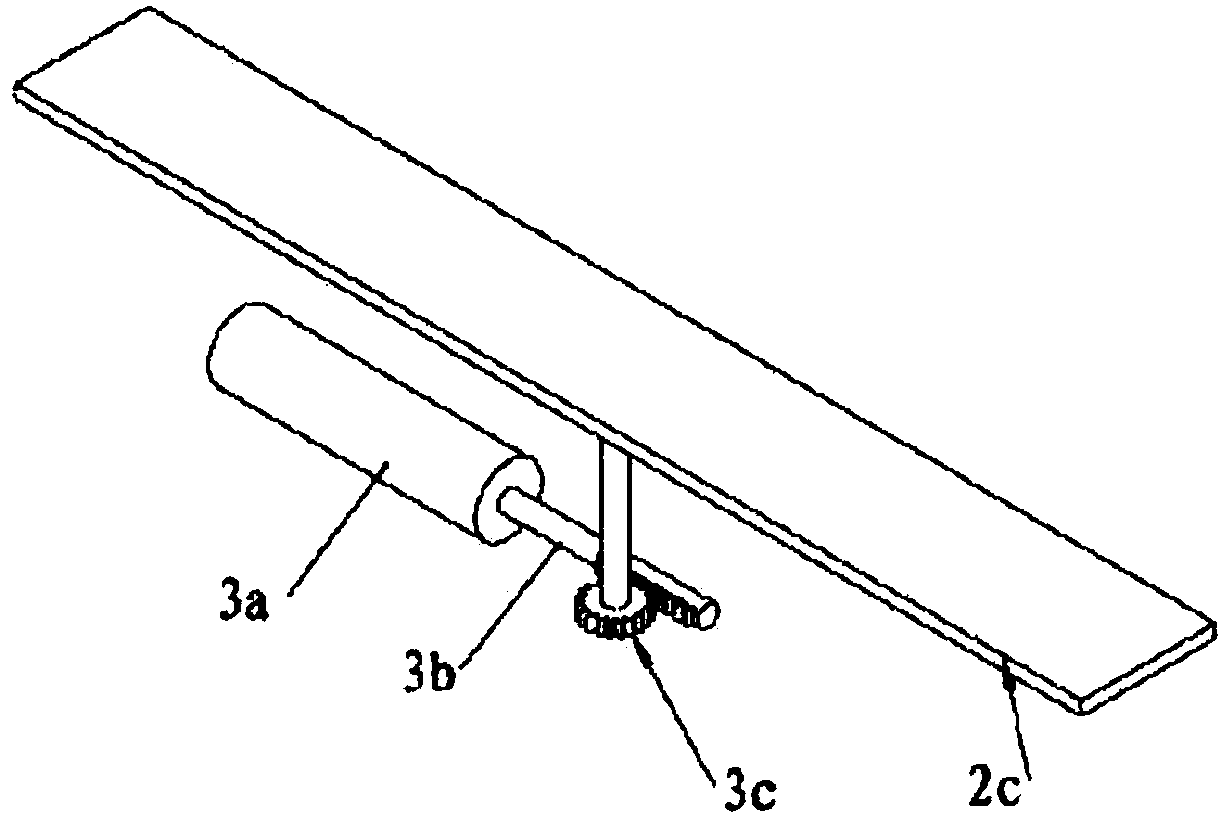

[0035] The basic structure of the quartz glass bulb automatic flame polishing device provided by the present invention includes: a frame 1, a quartz glass bulb support bracket 2c, a quartz glass bulb bearing vertical shaft 2d, a processing batch switching mechanism 3, a quartz glass bulb rotation mechanism 4, Polishing special burner 5, burner moving mechanism 6, limit feedback mechanism 7, control mechanism 8.

[0036] Wherein, the quartz glass bulb supporting bracket 2c is provided with two processing batch areas, each processing batch area is provided with a pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com