Blue disperse dye and its composition, preparation method and application

A disperse dye and composition technology, applied in the chemical field, can solve the problems of skin irritation, environmental protection, and low light fastness, and achieve the effects of low dye cost, good dyeing performance, and considerable development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

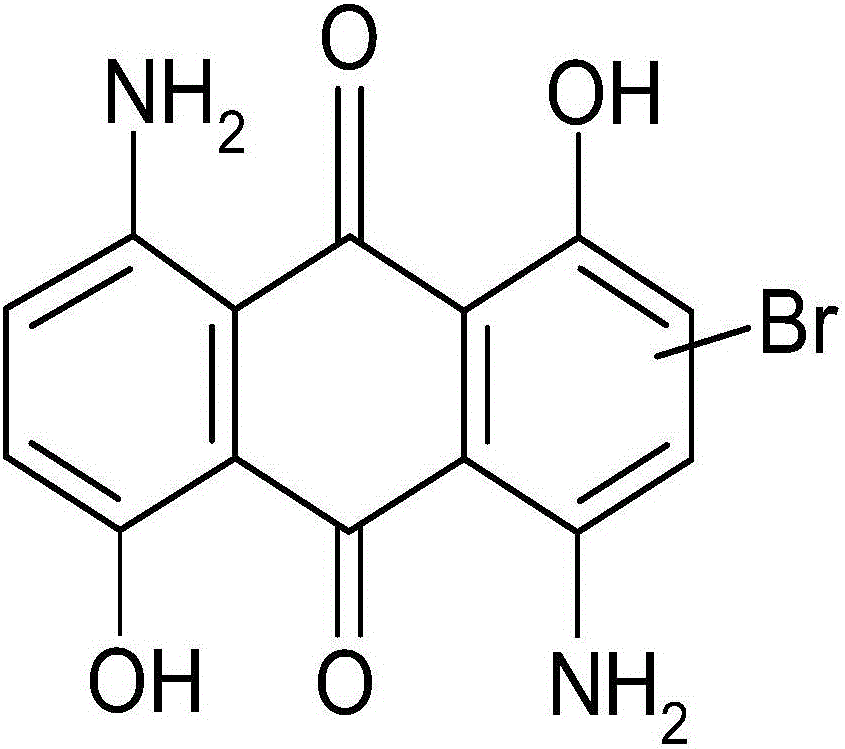

Image

Examples

Embodiment 1

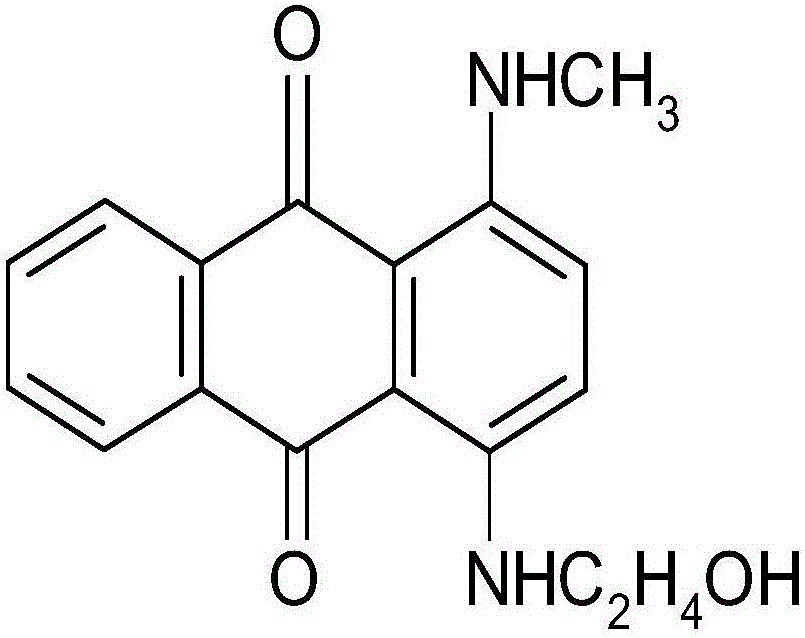

[0039] The chemical structure of the dyestuff of embodiment 1 of the present invention is as follows:

[0040]

[0041] Its preparation method is:

[0042] Dissolve 19.6 grams of 3-amino-5-nitro-2.1 benzisothiazole in 70 milliliters of 93-98% sulfuric acid, then add 40% nitrosyl sulfuric acid dropwise at 0-30 degrees, and keep the temperature until the end point. Obtained diazo liquid, to be coupled.

[0043] Dissolve 25 grams of N-ethyl-N-3-chloro-2-propanol-m-toluidine in a solution of 10 grams of sulfuric acid and 500 ml of water, add an appropriate amount of crushed ice, and then add the above-mentioned Diazo solution, keep warm until the diazo component disappears as the end point, filter and wash until neutral, and obtain a dye filter cake with a dry product of about 38 grams. After commercial processing, the dyed polyester fiber is brilliant blue. Detected λ max =620nm.

Embodiment 2

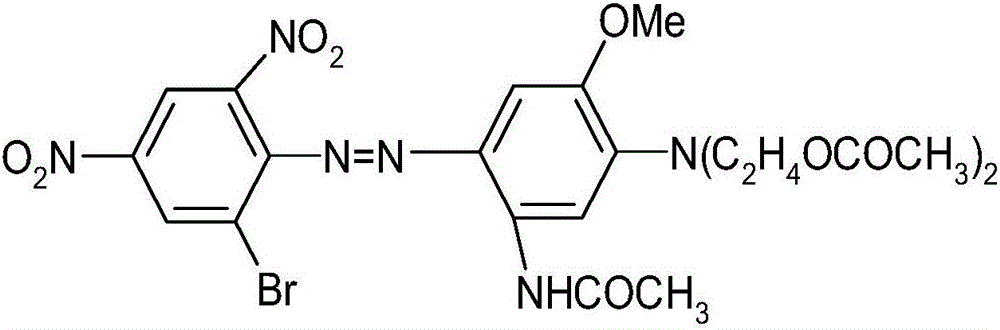

[0045] The chemical structure of embodiment 2 dyestuff of the present invention is as follows:

[0046]

[0047] Dissolve 19.6 grams of 3-amino-5-nitro-2.1 benzisothiazole in 70 milliliters of 93-98% sulfuric acid, then add 40% nitrosyl sulfuric acid dropwise at 0-30 degrees, and keep the temperature until the end point. Obtained diazo liquid, to be coupled.

[0048] Dissolve 31 grams of N-p-methylbenzyl-N-3-chloro-2-propanol-m-toluidine in a solution of 10 grams of sulfuric acid and 500 milliliters of water. After stirring to completely dissolve, add an appropriate amount of crushed ice to cool down to below 0 degrees. Slowly add the diazonium salt into the coupling solution, and keep the reaction at 0-5 degrees until the diazonium salt disappears. Filter water and wash to neutral to obtain a blue dye filter cake. After commercial processing, dyed polyester fiber is bright blue. Detected λ max = 616nm.

Embodiment 3

[0050] The chemical structure of embodiment 3 dyestuff of the present invention is as follows:

[0051]

[0052] Dissolve 19.6 grams of 3-amino-5-nitro-2.1 benzisothiazole in 70 milliliters of 93-98% sulfuric acid, then add 40% nitrosyl sulfuric acid dropwise at 0-30 degrees, and keep the temperature until the end point. Obtained diazo liquid, to be coupled.

[0053] Dissolve 30 grams of N-butyl-N-3-chloro 2-acetoxypropylaniline in a solution of 10 grams of 93% sulfuric acid and 500 milliliters of water, stir to completely dissolve, add an appropriate amount of ice, and cool down to below 0 degrees, Slowly add diazonium solution, keep warm at 0-5 degrees until the diazonium salt disappears, filter and wash with water until neutral. Filter cake commercial processing, dyed polyester fiber is bright blue. Detected λ max = 613nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com