Truffle liquor and production process thereof

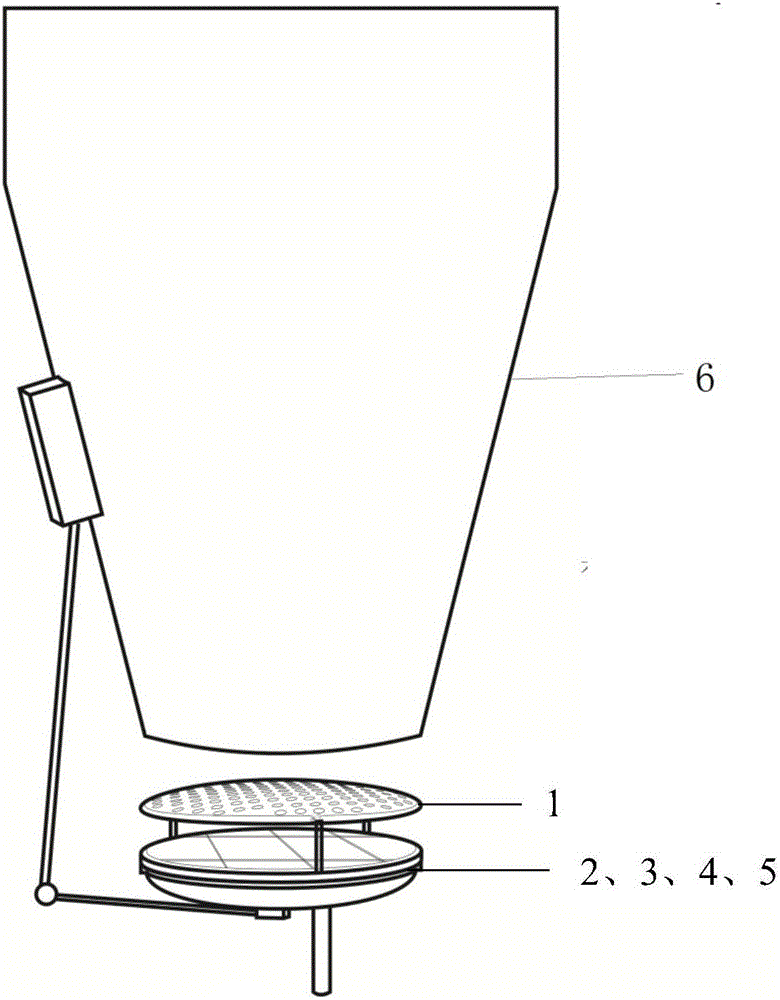

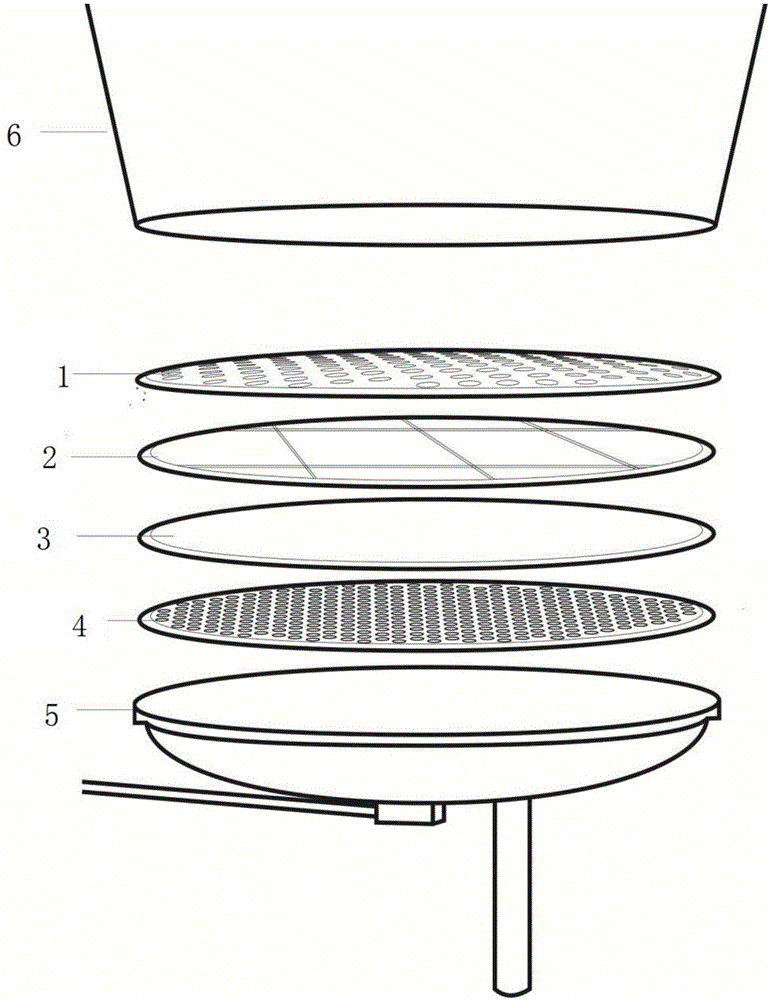

A production process and technology for truffle wine, applied in the field of truffle wine and its production process, can solve the problems of unstable color and transparency, unstable wine body, material liquid blocking, etc., and achieve stable color and transparency, wine body color and nutrition. The effect of stable composition and stable flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Thawing of raw materials: Thaw the frozen raw materials at 10°C for 12 hours, then cut them, and keep the cut particles at 0.5mm-1.5mm.

[0054] Ingredients: truffle: base wine mass ratio is 30%: 70%, base wine alcohol content 60% vol.

[0055] Percolation: the base wine controls the rate of percolation to 2ml / kg truffle particles. min.

[0056] Alcohol reduction: The percolated liquor and deionized water are subjected to alcohol reduction treatment at a mass ratio of 100:7, and the alcohol content after reduction is 42% vol.

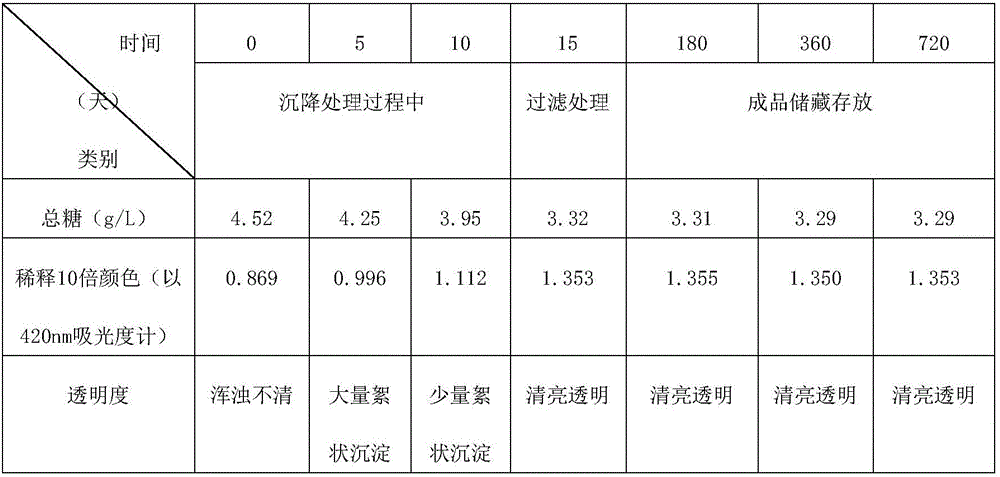

[0057] Settlement: With 5 days as a storage cycle unit, store for 3 cycle units. The first storage period: Store the obtained liquor at -12°C for 5 days (when the temperature of the liquor in the entire tank reaches the set temperature, the same below), pour the can after 5 days, discharge the sediment, and store the liquor in the tank. The liquor is circulated once. The second storage cycle: set the storage temperature at 15°C for 5 days, po...

Embodiment 2

[0063] Crushing of raw materials: The frozen raw materials were thawed at 4°C for 24 hours, then chopped, and the chopped particles were kept at 0.5mm-1.5mm.

[0064] Ingredients: truffle: base wine mass ratio is 50%: 50%, base wine alcohol content 68% vol.

[0065] Percolation: the base wine controls the rate of percolation to 4ml / kg truffle particles. min.

[0066] Alcohol reduction: The percolated liquor and deionized water are subjected to alcohol reduction treatment at a mass ratio of 100:1.18, and the alcohol content after reduction is 47% vol.

[0067] Settlement: Take 7 days as a storage cycle unit, and store for 5 cycle units. The first storage cycle: store the obtained liquor at -10°C for 7 days (when the temperature of the liquor in the entire tank reaches the set temperature, the same below), pour the can after 7 days, discharge the sediment, and store the liquor in the tank. The liquor is circulated once. The second storage period: set the storage temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com