Manufacturing method of track iron backing plate structure in rail transit engineering

A technology of rail transit engineering and production method, which is applied in the field of production of rail iron backing plate structure, can solve the problems of low design value of sleeper top surface, sleeper error of track bed, etc. A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The manufacturing method of the track iron backing plate structure in the track traffic engineering of the present invention is described in conjunction with the accompanying drawings.

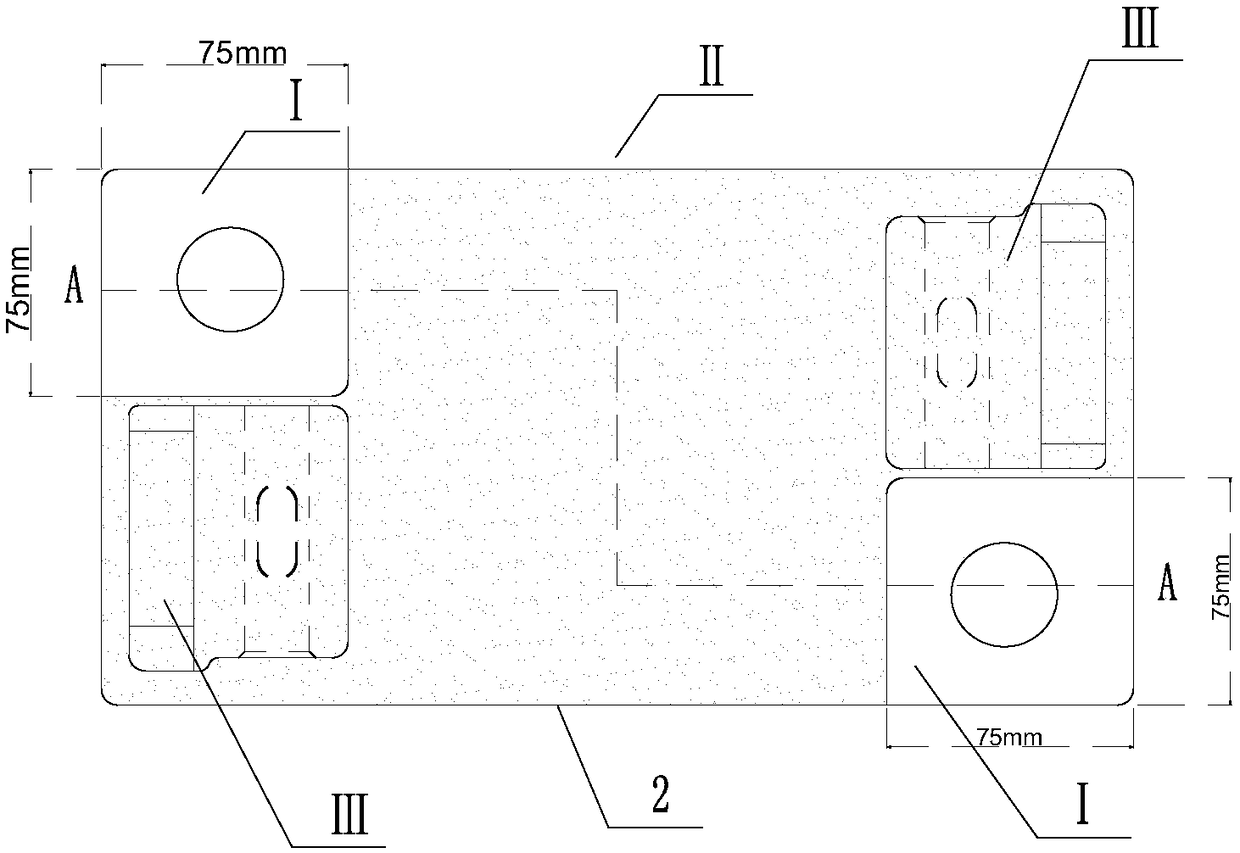

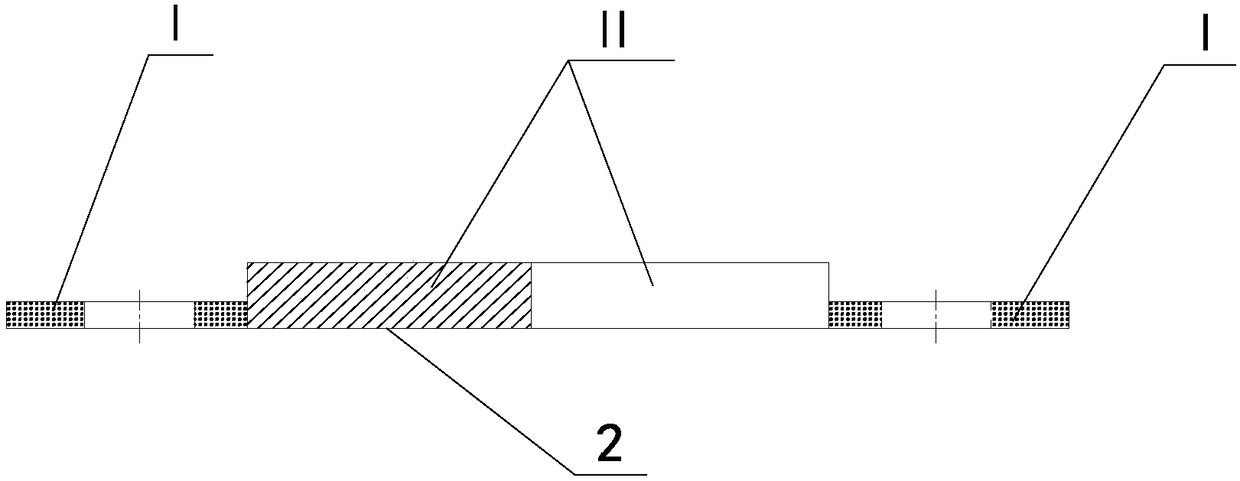

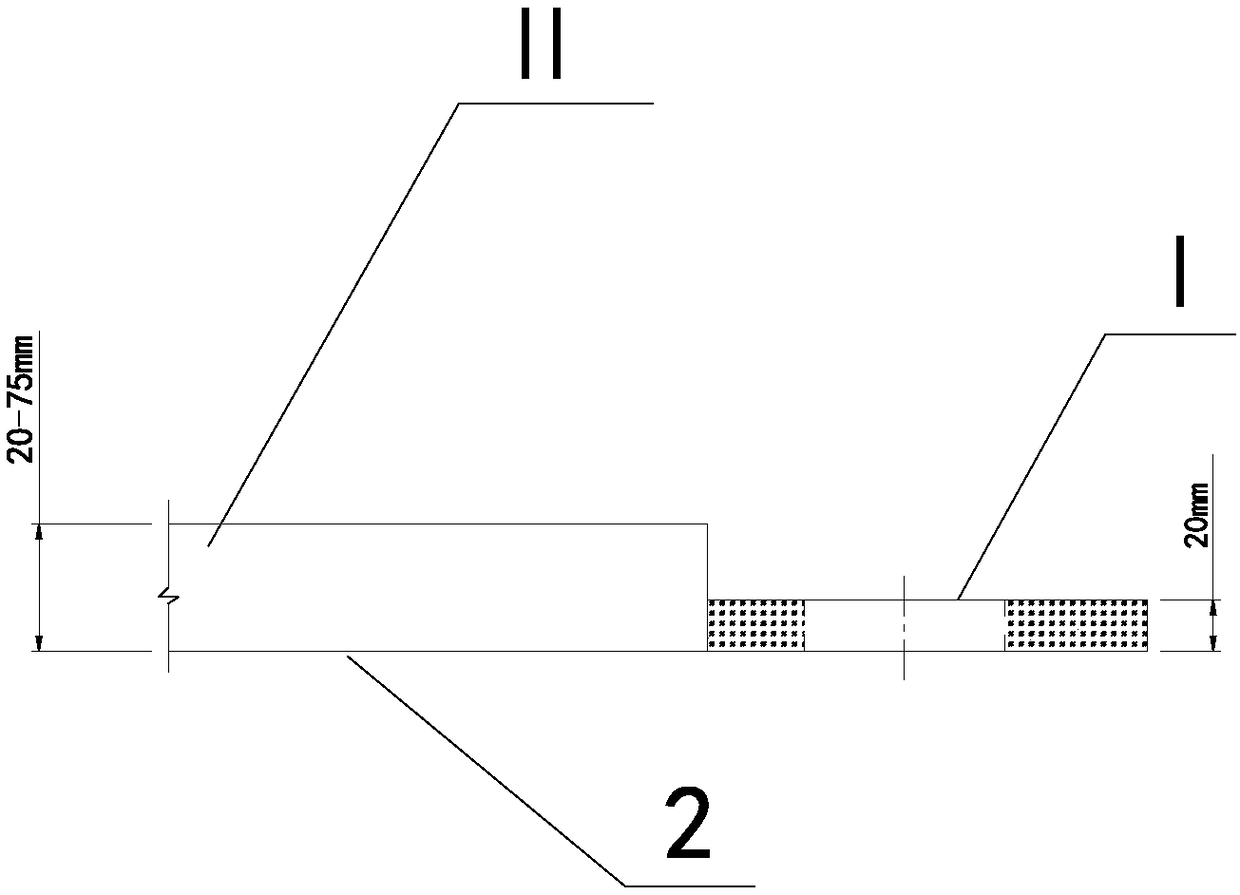

[0020] The design concept of the new iron backing plate structure of the rail transit engineering track of the present invention is based on: the original iron backing plate is also divided into three areas: the spike fixing area I, the supporting rail area II, and the spring strip fixing area III. The thickness is the same, generally 20mm, and can be appropriately reduced if necessary. The biggest difference between the structure of the iron backing plate and the original iron backing plate is that the thickness of the spike fixing area I remains unchanged. After the finite element analysis calculation and the actual project application test, the most reasonable 20mm is used, and it can be appropriately reduced if necessary. figure 2 As shown, the thickness values of the supporting ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap