Magnetic fluid variable-damping energy dissipation bracing with reset function

An energy-consuming support, magnetic fluid technology, applied in building components, earthquake resistance, building types, etc., can solve problems such as the inability to effectively ensure the structural safety under earthquakes, the large sliding force of self-resetting components, and the inability to provide restoring force, etc., to avoid The effect of changing and welding residual stress, eliminating residual deformation and reducing welding range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to illustrate the present invention more clearly, the present invention will be further described below with reference to the preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

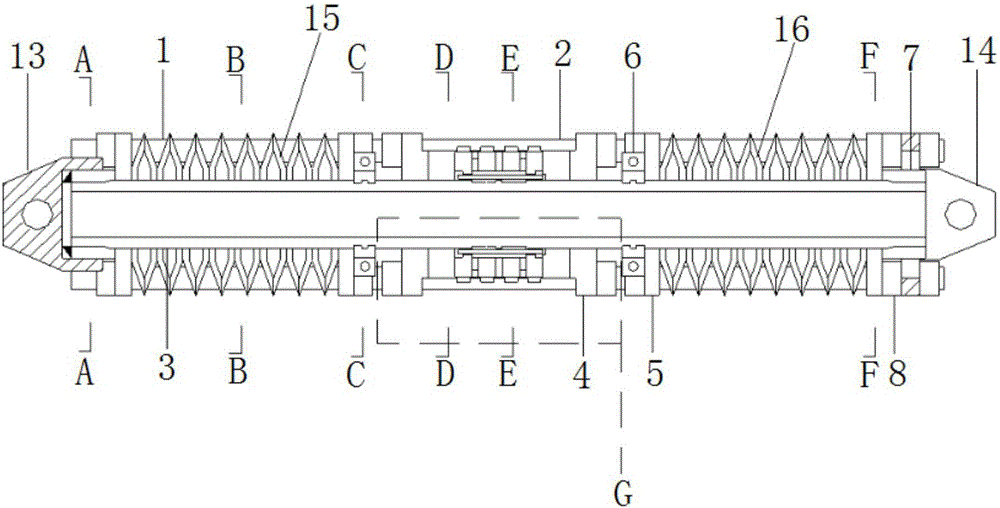

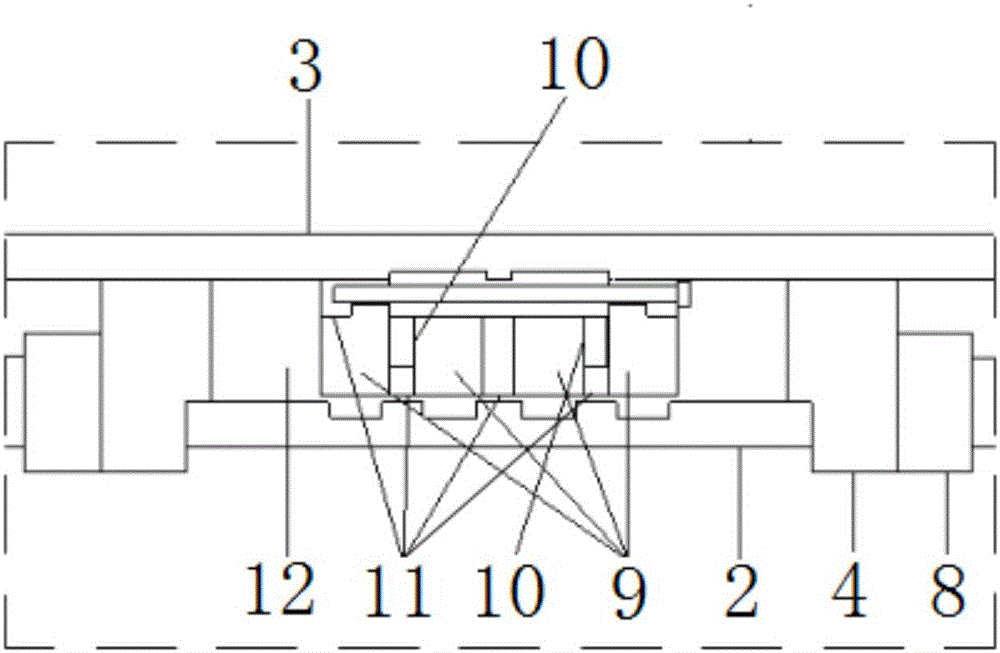

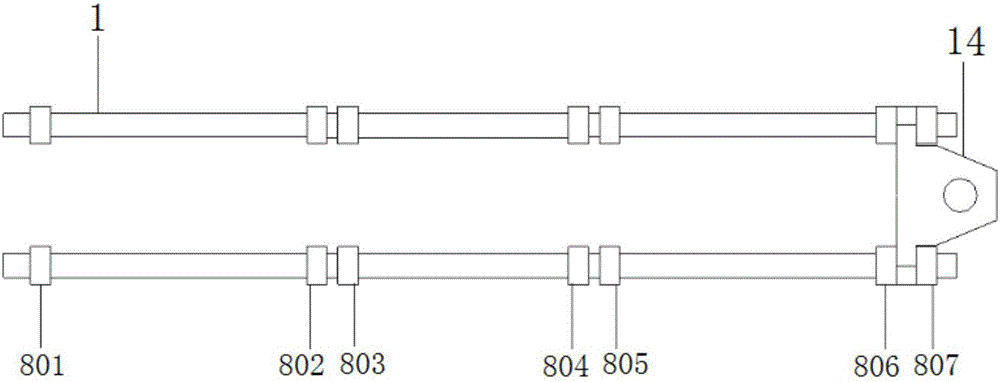

[0036] like Figure 1-Figure 10 As shown, a magnetic fluid variable damping energy dissipation support with reset function includes a guide shaft combination, an inner tube combination, a self-resetting device and an energy dissipation device, and the inner tube combination includes an inner tube 3, a disc spring end plate stopper 6 and inner tube end block 7, the guide shaft combination includes a guide shaft 1 and a guide shaft nut 8, and the self-reset device includes a left disc spring 15, a right disc spring 16 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com