A Correction Method for Residual Deformation of Aluminum Alloy Thin Flat Castings

A residual deformation, aluminum alloy technology, applied in the field of correction of residual deformation of aluminum alloy thin plate castings, can solve problems such as affecting product appearance, low production efficiency, changing design dimensions, etc., to improve stability and reliability, accurate and detailed data , the effect of eliminating residual deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing:

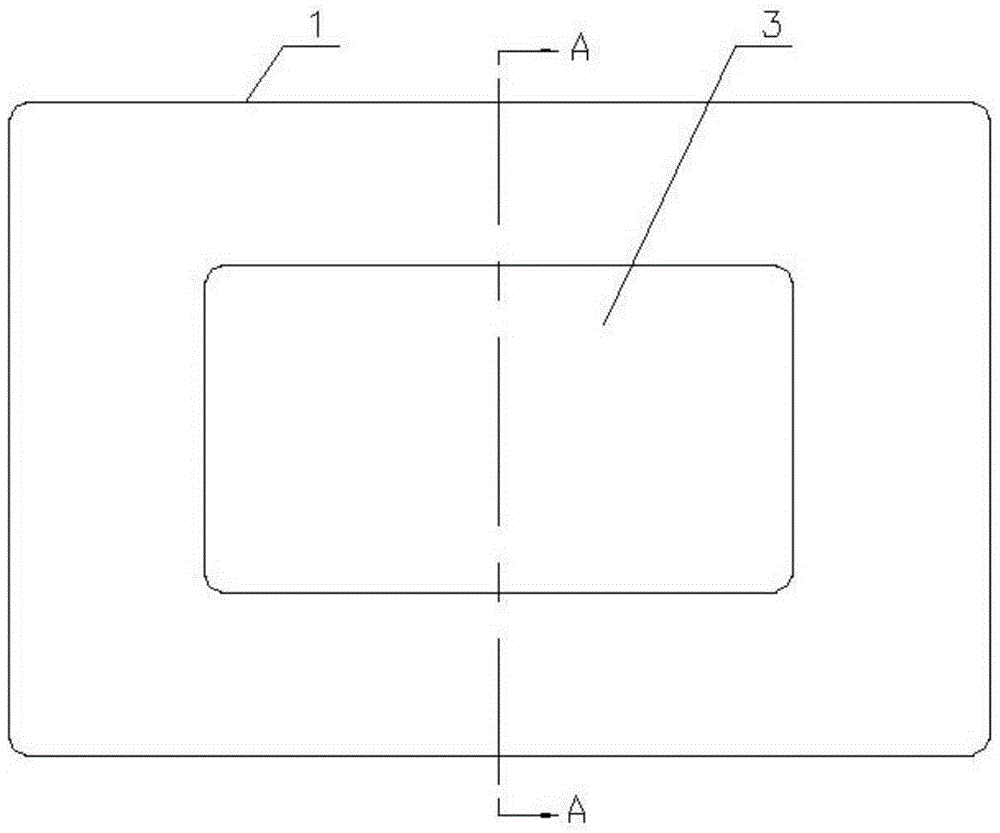

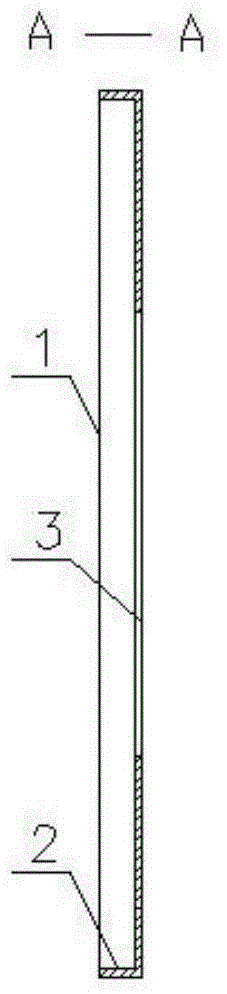

[0045] figure 1 , 2 Shown is the structural diagram of the aluminum alloy thin flat casting. The plane size of the aluminum alloy thin flat casting 1 is ≦300mm in length, ≦200mm in width, and the thickness of the flat part is ≦2.5mm. The thickness is consistent, and a square hole 3 is provided in the middle.

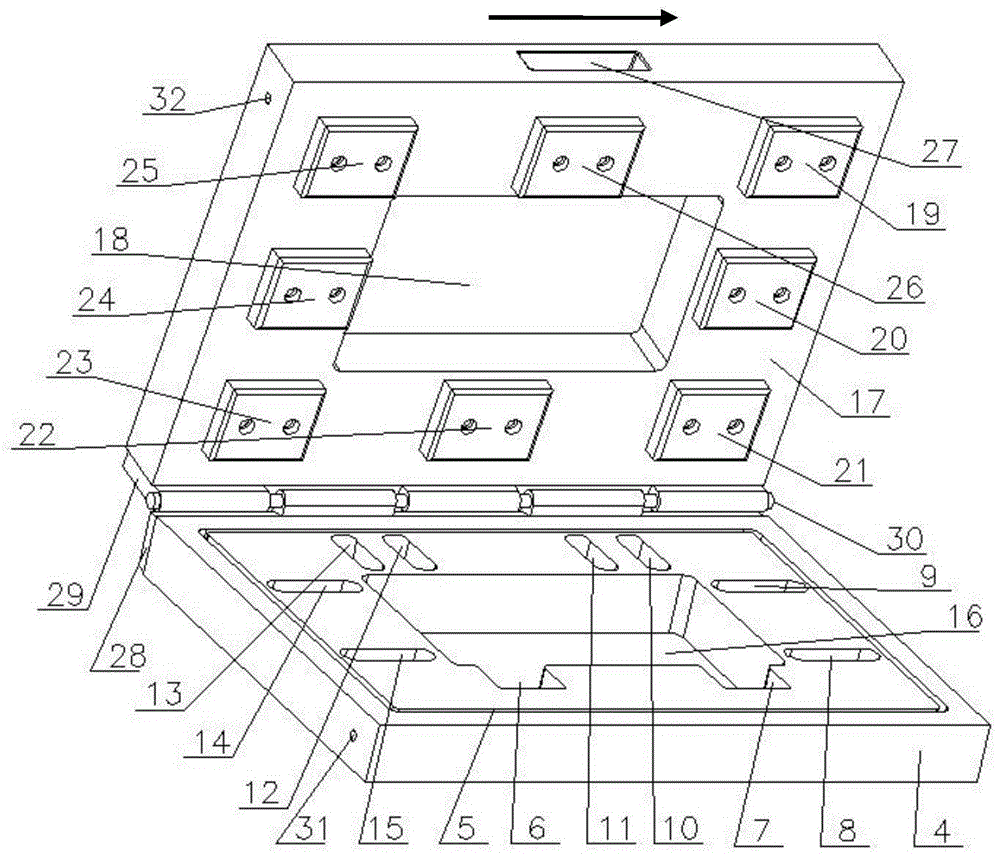

[0046] image 3 As shown, it is the structural diagram of the correction fixture. The correction fixture is composed of a lower fixture, an upper fixture, a lower fixture connector, an upper fixture connector, a connecting shaft, and a fixed block;

[0047] The main structure of the lower fixture includes: the lower fixture reference plate, the annular groove, the U-shaped groove, the deformation adjustment groove, the lower fixture square groove, and the lower fixture fixing hole;

[0048] The lower fixture reference plate 4 is a reference frame, and an annular g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com