Intelligent floor and construction method thereof

A construction method and intelligent technology, applied in the direction of floors, building components, buildings, etc., can solve the problems of poor mechanical performance of hollow floor slabs, and the inability of concrete bottom plates to participate in floor heating adjustment, and achieve convenient layout, simplified maintenance work, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

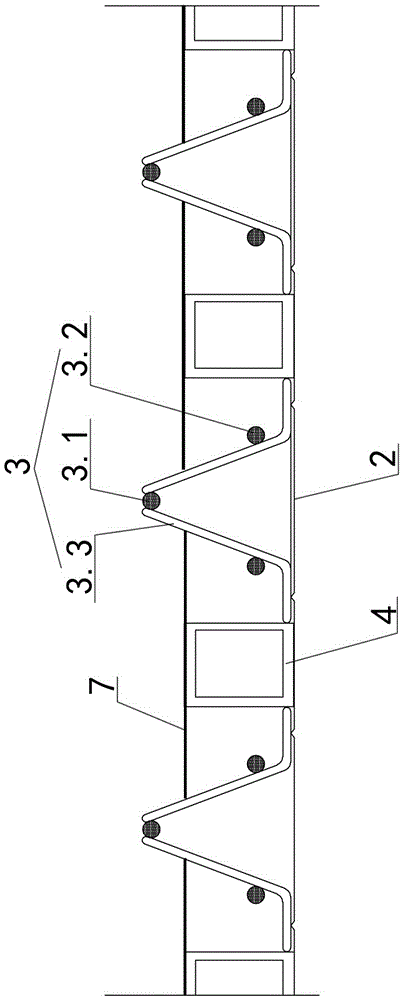

[0043] Embodiment one, see Figure 1-4 As shown, an intelligent floor slab includes a slab body, and the slab body includes a slab body concrete 1, a self-supporting profiled steel plate bottom form 2 at the bottom, embedded in the slab body concrete and fixed on the self-supporting profiled steel plate bottom A group of steel bar trusses 3 and a group of smart device tubes 4 on the upper side of the mold 2, the smart device tubes 4 are parallel to the steel bar trusses 3 along the longitudinal direction of the plate body, and are distributed between the steel bar trusses 3 at intervals along the transverse direction of the plate body. The smart device pipe 4 includes at least one hollow pipe through which the valve 5 in the pipe controls the ventilating and water-passing equipment outside the board, and the connection circuit in the pipe controls the induction device outside the board; those skilled in the art can implement the valve in any reliable manner. 5 Connection with ...

Embodiment 2

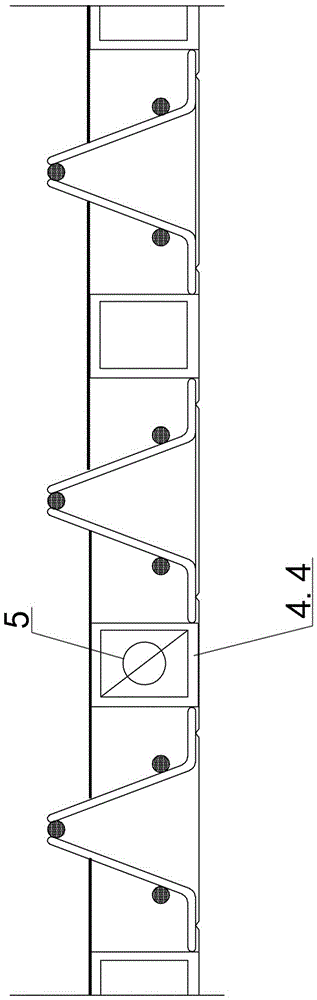

[0050] Embodiment two, see Figure 5 As shown, the difference from the first embodiment is that the smart device tubes 4 are all round tubes, and no ordinary hollow tube 4.1 is provided.

Embodiment 3

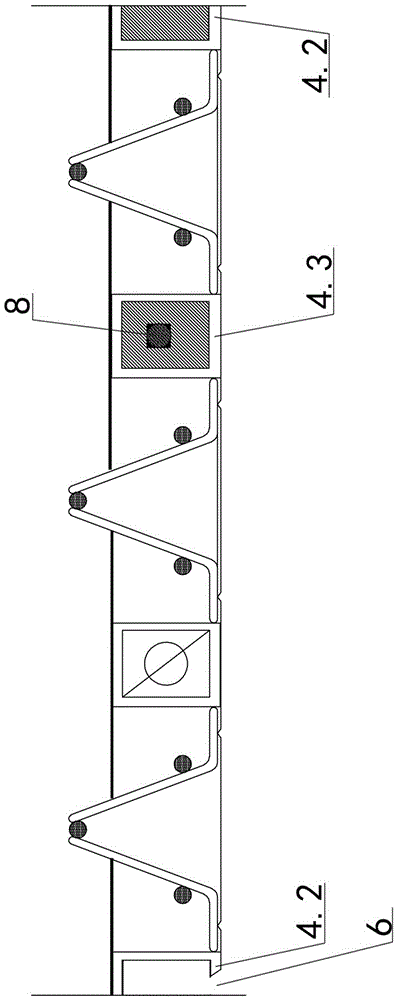

[0051] Embodiment three, see Image 6 As shown, the difference from the second embodiment is that all smart device tubes 4 are T-shaped tubes, and ordinary hollow tubes 4.1 are not provided.

[0052] The construction method of the intelligent floor slab of embodiment 1 includes the following construction steps:

[0053] Step 1: Process the self-supporting profiled steel plate base form 2, the steel bar truss 3 and the smart device tube 4 in the prefabricated component factory, design the type, shape and number of the smart device tube 4 according to the actual situation, and place them on the self-supporting profiled steel plate The bottom mold 2 is fixedly connected to the steel bar truss 3 and the intelligent device pipe 4, and the binding limit pressure piece 7 is fixed between the connected steel bar trusses 3 and on the upper side of the intelligent device pipe 4 to form a floor deck unit;

[0054] Step 2, the prefabricated floor deck unit is transported to the site, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com