Gas drilling and coring tool

A gas drilling and coring technology, which is applied in the direction of extracting undisturbed core devices, earthwork drilling and mining, etc., can solve the problems of low average yield of cores, core jamming, core grinding, adverse effects of geological exploration, etc., and achieve the goal of increasing the average yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

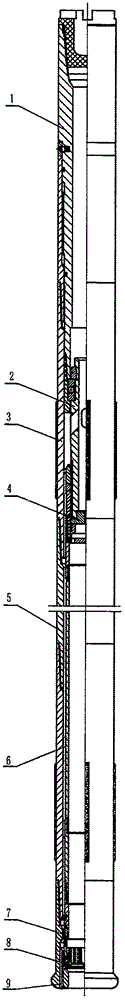

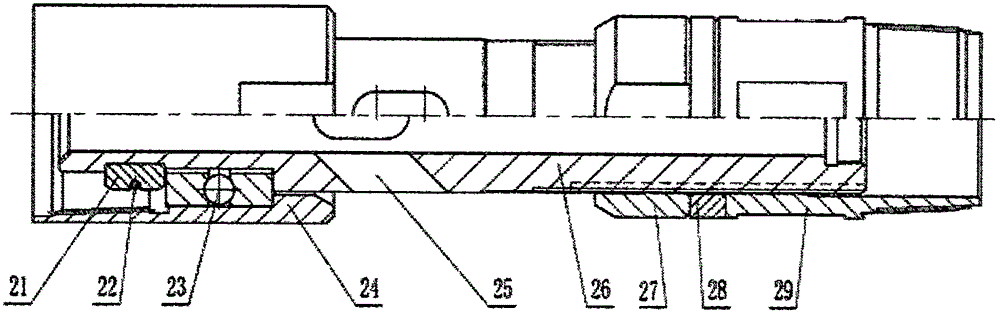

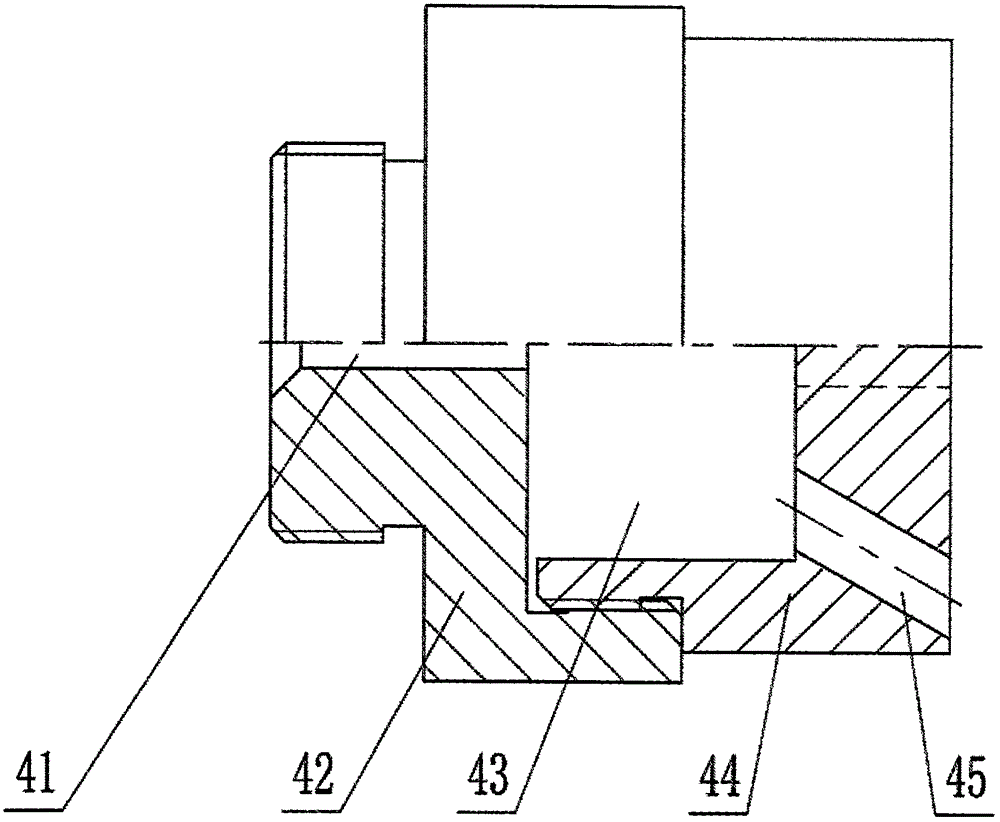

[0018] like figure 1 As shown, the embodiment of the present invention provides a gas drilling coring tool, including a safety joint 1, a rotating assembly 2, a difference nipple 3, a gas splitter joint 4, a coring outer cylinder 5, a coring inner cylinder 6, The core claw assembly 7, the drill bit throat sealing device 8 and the gas coring bit 9, the middle part of the safety joint 1 is threaded with the difference nipple 3, and the lower part is threaded with the rotating assembly 2; the lower part of the rotating assembly 2 It is threadedly connected with the gas distribution joint 4; the lower part of the gas distribution joint 4 is threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com