Method for reducing impurities in ethyl diketone 11a hydroxylation process by using mixed solvent

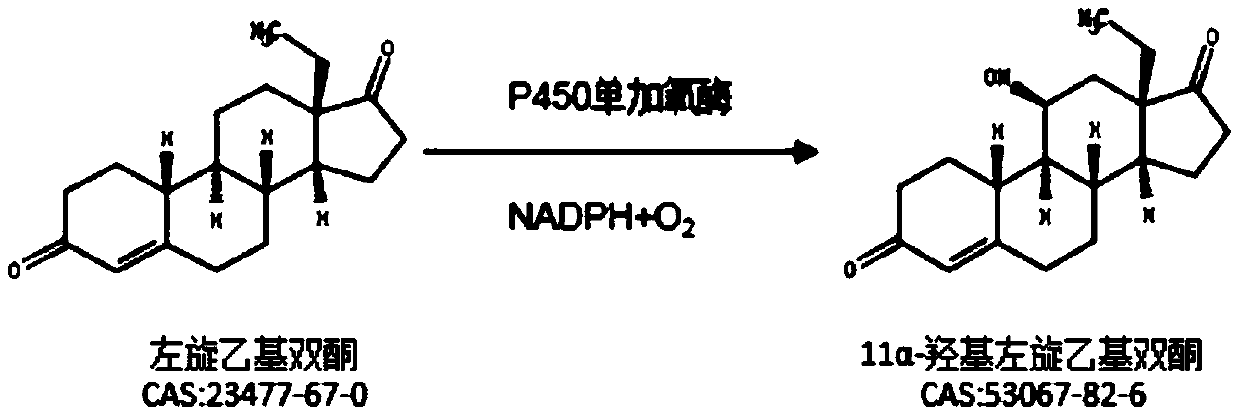

A mixed solvent and ethyl diketone technology is applied in the field of using mixed solvents to reduce impurities in the hydroxylation process of ethyl diketone 11a. It can solve the problems of many impurity points and cumbersome and difficult treatment processes, and achieve high conversion rate of substrates. The effect of increasing the average yield and improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

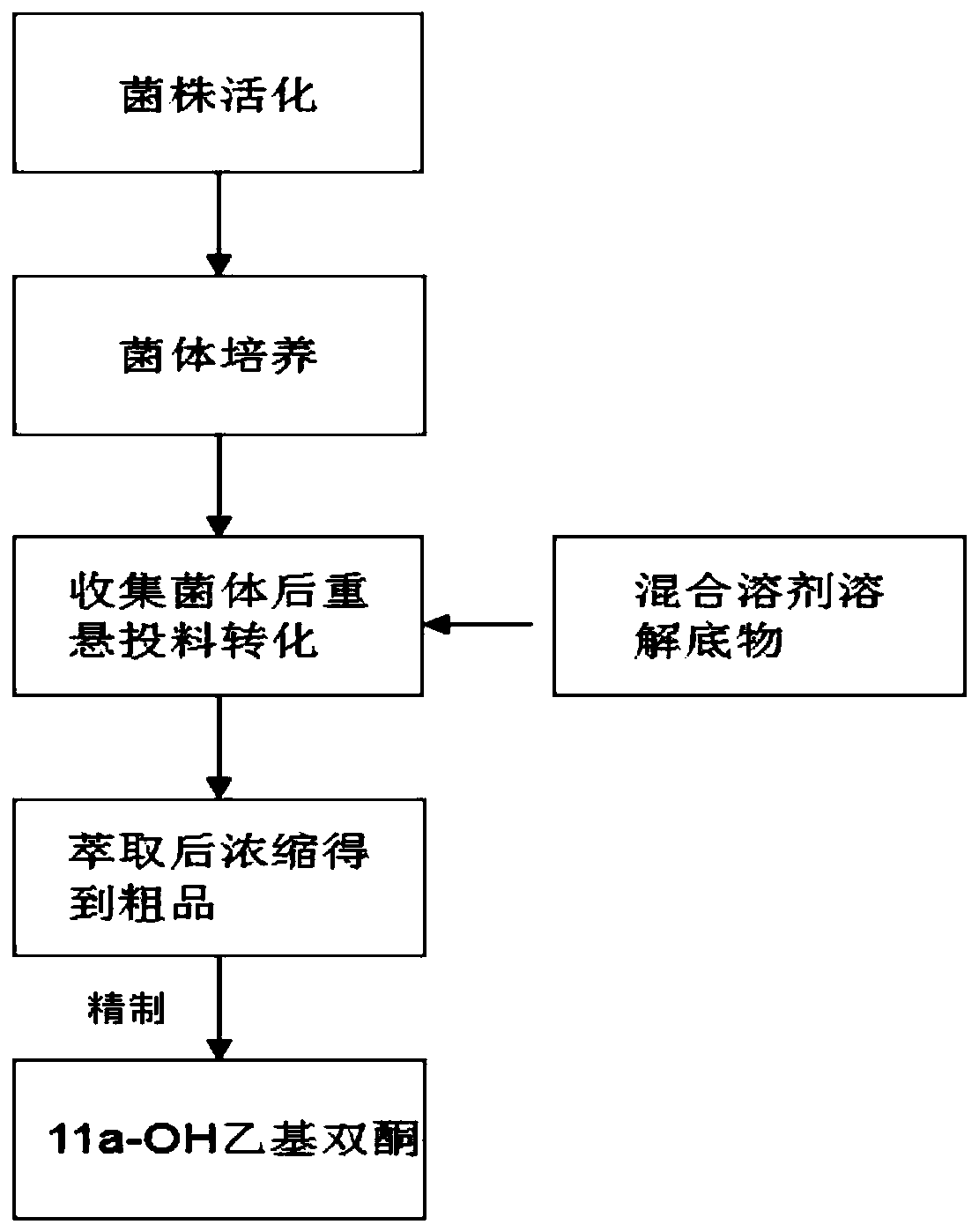

[0042] Such as figure 1 As shown, Metarhizium anisopliae was inoculated on a potato dextrose agar (PDA) medium for culture, and cultured at 28° C. for 3-10 days.

[0043] Take one ring and transfer it to the culture medium of the shaker flask, the rotation speed of the shaker culture is 150rpm, the culture temperature is 27°C, the liquid medium is 8.5g / L glucose, 8.5g / L soybean powder, 4g / L silkworm chrysalis powder, and cultivate for 14h .

[0044] The cultivation time of the small tank was 16 hours, the cultivation temperature was 27°C, and the ventilation volume was 0.5vvm.

[0045] Feed transformation after collecting the bacteria, the mass ratio of the substrate to the bacteria is 1:7, the substrate DL-18-methyl-40estrenene-3,17-dione is dissolved in 500mL of a mixed solvent of DMF and DMSO, and the temperature is 55 °C, volume ratio DMF:DMSO=5:1, feed concentration 4g / L, feed amount 56g, conversion at 24°C for 24h, temperature raised to 70°C for 5min, and reaction term...

Embodiment 2

[0047] Such as figure 1 As shown, Metarhizium anisopliae was inoculated on a potato dextrose agar (PDA) medium for culture, and cultured at 28° C. for 3-10 days.

[0048] Take one ring and transfer it to the shake flask culture medium, the shaker culture speed is 160rpm, the culture temperature is 29°C, the liquid medium is 8.5g / L glucose, 8.5g / L soybean powder, 8.5g / L silkworm chrysalis powder, and culture 15h.

[0049] The cultivation time of the small tank was 30 hours, the cultivation temperature was 32°C, and the ventilation volume was 0.8vvm.

[0050] Feed transformation after collecting the bacteria, the mass ratio of the substrate to the bacteria is 1:1, the substrate is dissolved in DMF and DMSO, the temperature of the melting material is 60°C, the transformation is 24h, DMF:DMSO=8:1, the feeding concentration is 4g / L, Feed amount 50g, use solvent 500ml, transform at 32°C for 40h, raise the temperature to 70°C for 5min, stop the reaction, extract the bacteria with 500...

Embodiment 3

[0052] Such as figure 1 As shown, Metarhizium anisopliae was inoculated on a potato dextrose agar (PDA) medium for culture, and cultured at 28° C. for 3-10 days.

[0053] Take one ring and transfer it to the culture medium of the shaker flask, the rotation speed of the shaker culture is 180rpm, the culture temperature is 30°C, the liquid medium is 8.5g / L glucose, 8.5g / L soybean powder, 4g / L silkworm chrysalis powder, and cultivate for 16h .

[0054] The cultivation time of the small tank was 24 hours, the cultivation temperature was 27°C, and the ventilation volume was 1.2vvm.

[0055] After collecting the bacteria, the mass ratio of the substrate to the bacteria is 1:10, the substrate is dissolved in DMF and DMSO, and the transformation takes 24 hours. DMF:DMSO=10:1, the feeding concentration is 4g / L, the feeding amount is 60g, and the solvent is used 500ml, melt temperature 70°C, transform at 40°C for 24h, raise the temperature to 70°C for 5min, terminate the reaction, ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com