Nut with improved structure

A nut and nut body technology, applied in the direction of nuts, connecting components, threaded fasteners, etc., can solve the problems of inconvenient disassembly and installation of nuts, insufficient light, easy damage of nuts, etc., to achieve labor-saving assembly and disassembly, and reduce damage and failure. risk, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

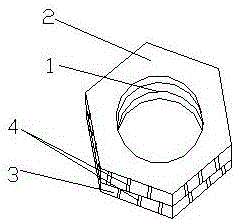

[0017] Such as figure 1 As shown, a nut with an improved structure of the present invention includes a nut body 2 with a thread 1, a buffer layer 3 is installed on the bottom side of the nut body 2, and the buffer layer 3 is detachably connected with the nut body 2. On the nut body 2 and the buffer layer 3, a number of luminous strips 4 are evenly distributed along the circumferential direction of the nut body 2 and the buffer layer 3, and the outer surfaces of the nut body 2 and the buffer layer 3 are provided with a layer of anti-corrosion layer .

[0018] Preferably, as the second embodiment, this embodiment is a further limitation of the first embodiment, the anti-corrosion layer is a fluorocarbon coating.

[0019] Preferably, as the third embodiment, this embodiment is also a further limitation of the first embodiment, the luminous strip 4 protrudes beyond the nut body 2 and the buffer layer 3 to a certain height.

[0020] Preferably, as the fourth embodiment, this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com