Coupling sleeve assembly, double-shaft type servo motor and automatic equipment

A technology of servo motors and coupling sleeves, which is applied to mechanical equipment, couplings, electric components, etc., and can solve problems such as front and rear shaft wear, poor coaxiality of front and rear shafts, and inability to fully fit tightly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

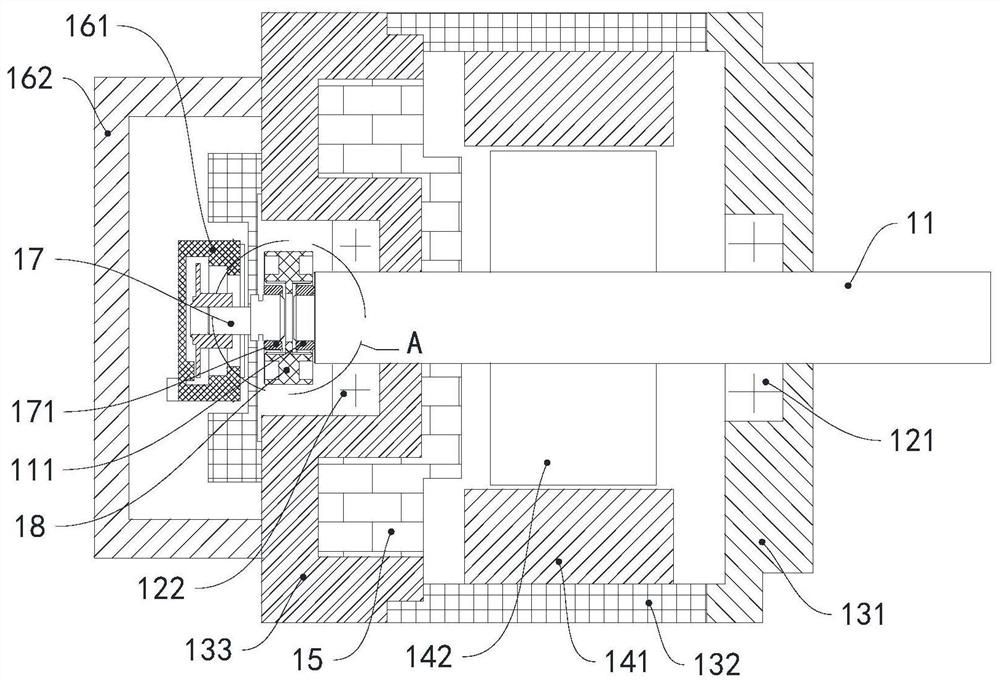

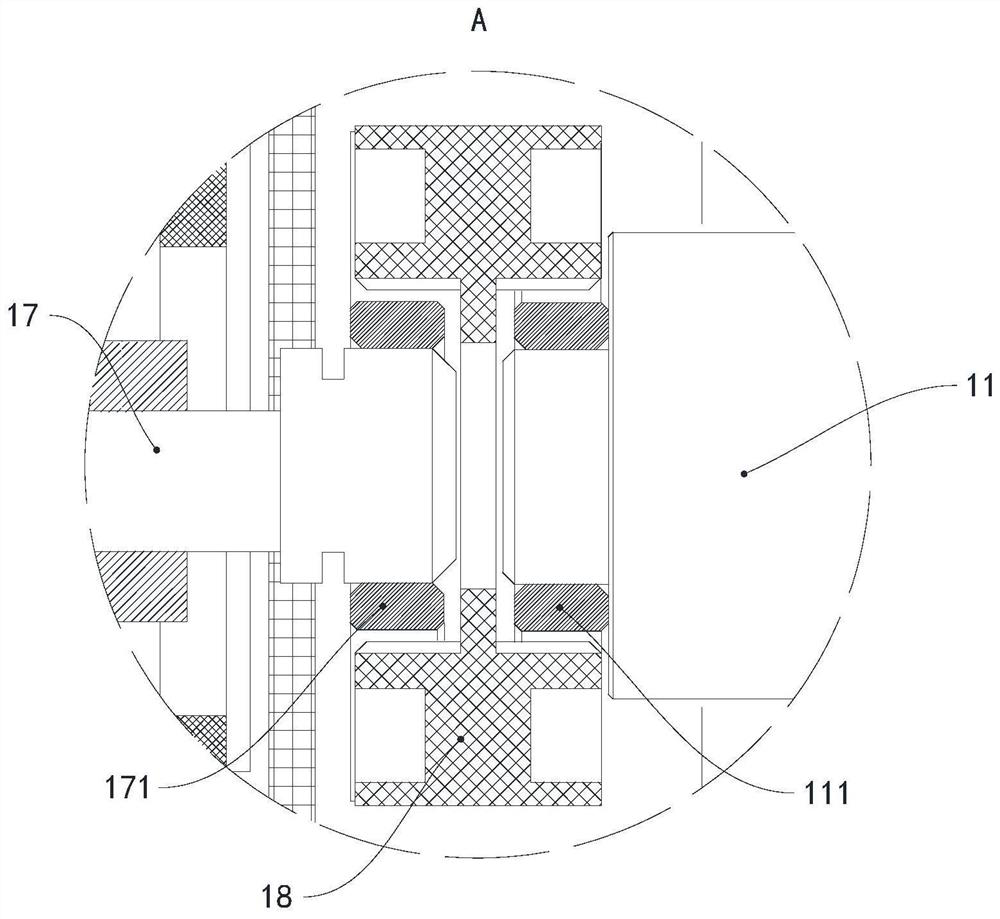

[0035] The first embodiment of the shaft coupling sleeve assembly and the double-shaft servo motor

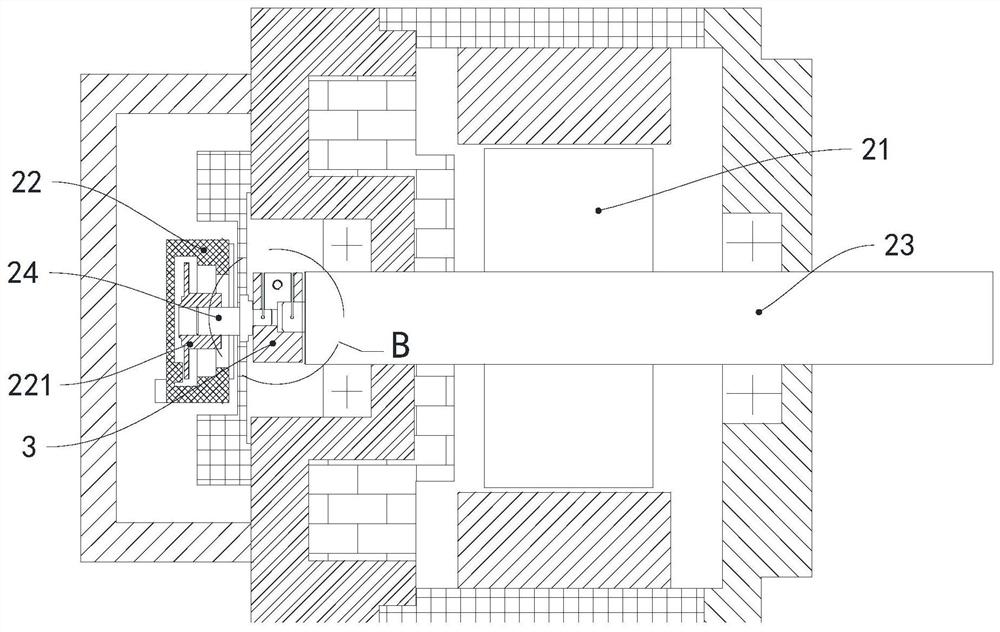

[0036] see Figure 3 to Figure 5 , The biaxial servo motor includes a rotor 21, an encoder 22, a motor front shaft 23, a motor rear shaft 24 and a coupling sleeve assembly. The motor front shaft 23 is fixedly connected to the rotor 21, the motor rear shaft 24 is fixedly connected to the code disc 221 of the encoder 22, the motor front shaft 23 is connected to the motor rear shaft 24 through a coupling sleeve assembly, and the coupling sleeve assembly includes a shaft coupling Sleeve 3 and fixing piece 4 ( Figure 6 Shown), the coupling sleeve 3 is a plastic part, and the fixing part 4 is a screw.

[0037] The shaft coupling sleeve 3 is provided with a shaft sleeve hole 31 penetrating in the axial direction, and the motor front shaft 23 and the motor rear shaft 24 respectively extend into the shaft sleeve hole 31 from both ends of the shaft coupling sleeve 3 .

[0038] The pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com