Exposed Fuze Transport Vibration Test Fixture

A vibration test and fuze technology, applied in the field of fuzes, can solve the problems of easy resonance, low test efficiency, and non-compliance with the rigid connection between the fixture and the vibration table, to avoid resonance and avoid top-heavy effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

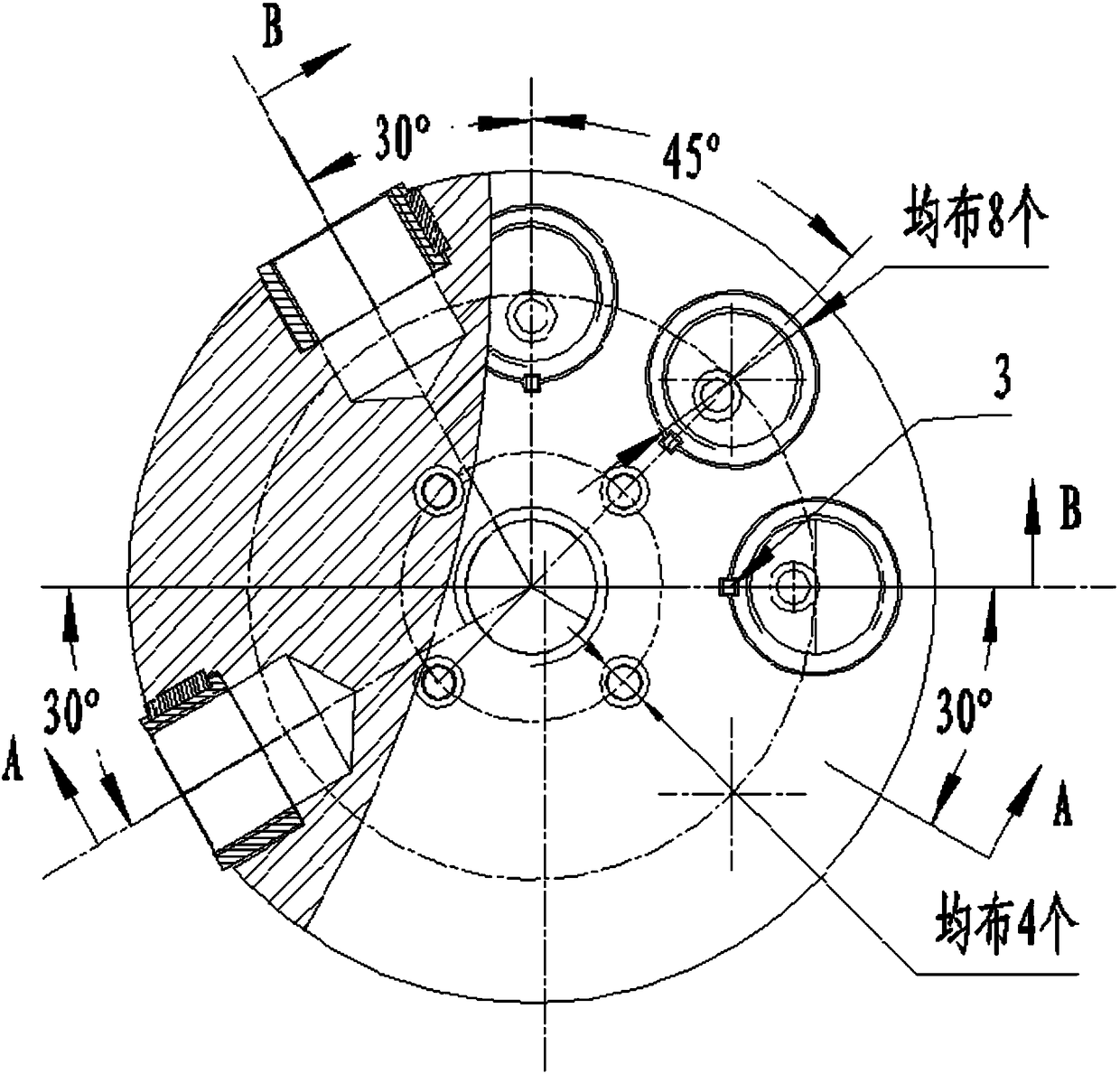

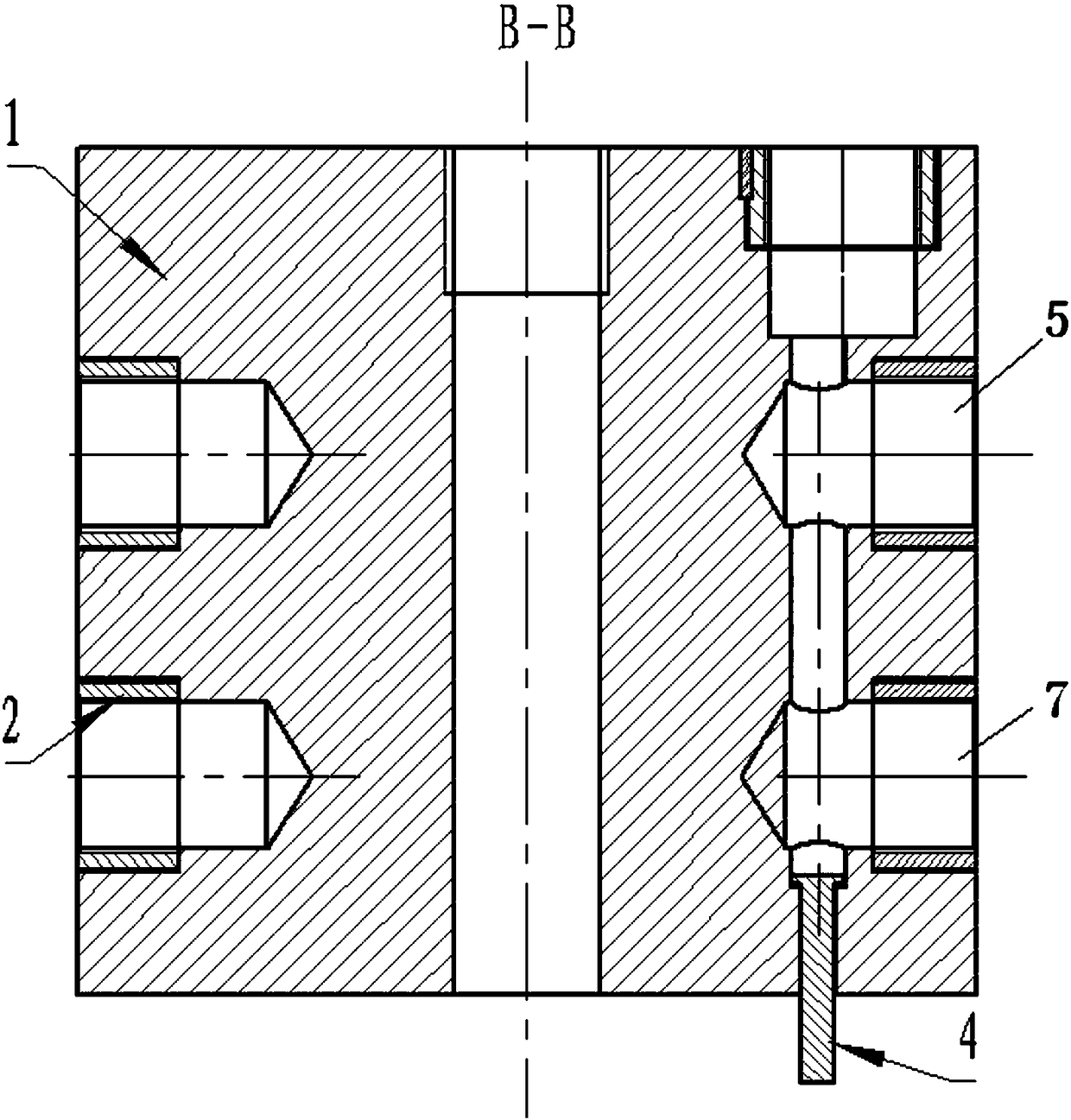

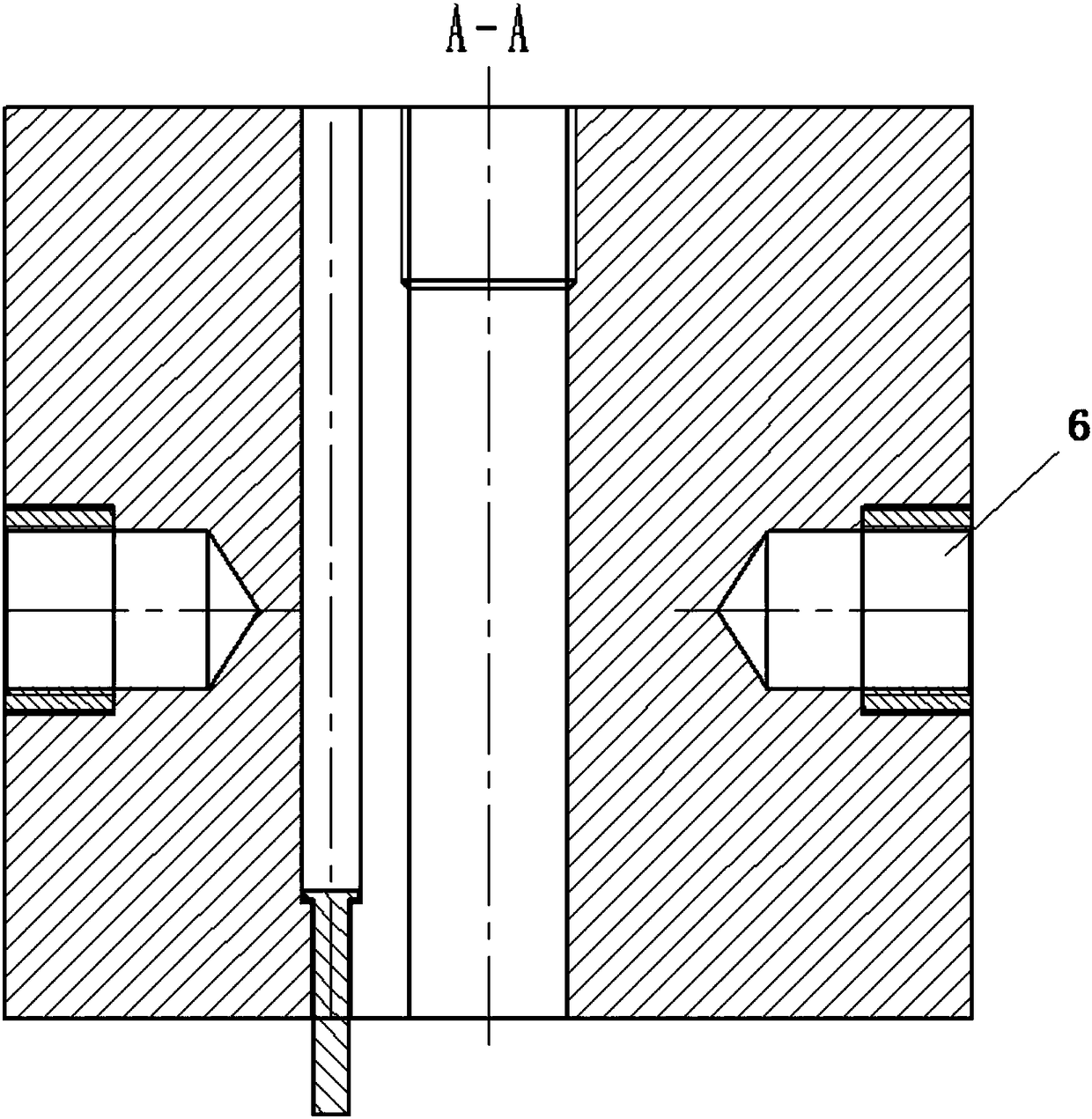

[0028] Such as Figure 1.1 As shown, a bare fuze transport vibration test fixture of the present invention includes: 1 body 1, 26 screw sleeves 2, 26 pin keys 3, and 12 connecting rods 4.

[0029] The body 1 is a cylinder with 27 fuze installation holes in total, one of which is the center hole of the cylinder, called the central installation hole, which is a through hole and has internal threads; the remaining 26 installation holes are light holes , The inner walls of the 26 mounting holes all leave a square groove compatible with the pin key 3, and the direction is arbitrary.

[0030] The upper ports of 9 of the 27 mounting holes are located on the upper end surface of the cylinder, including 1 central mounting hole and 8 vertical mounting holes. The axes of these 9 mounting holes are parallel to the central axis of the body 1 . The central mounting hole i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com