Fiber laser microphone with special-shaped spring type sensibilization structure

A special-shaped spring and fiber laser technology, applied in instruments, measuring ultrasonic/sonic/infrasonic waves, measuring devices, etc., can solve problems such as insufficient low-frequency detection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

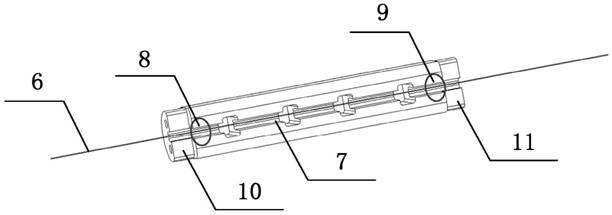

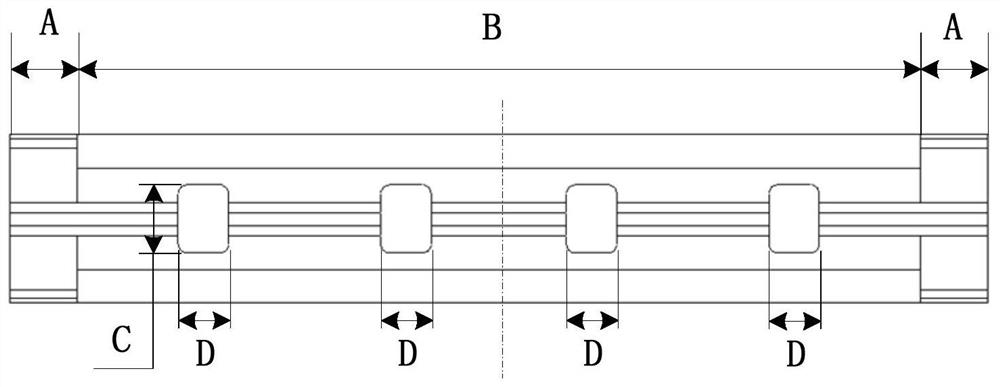

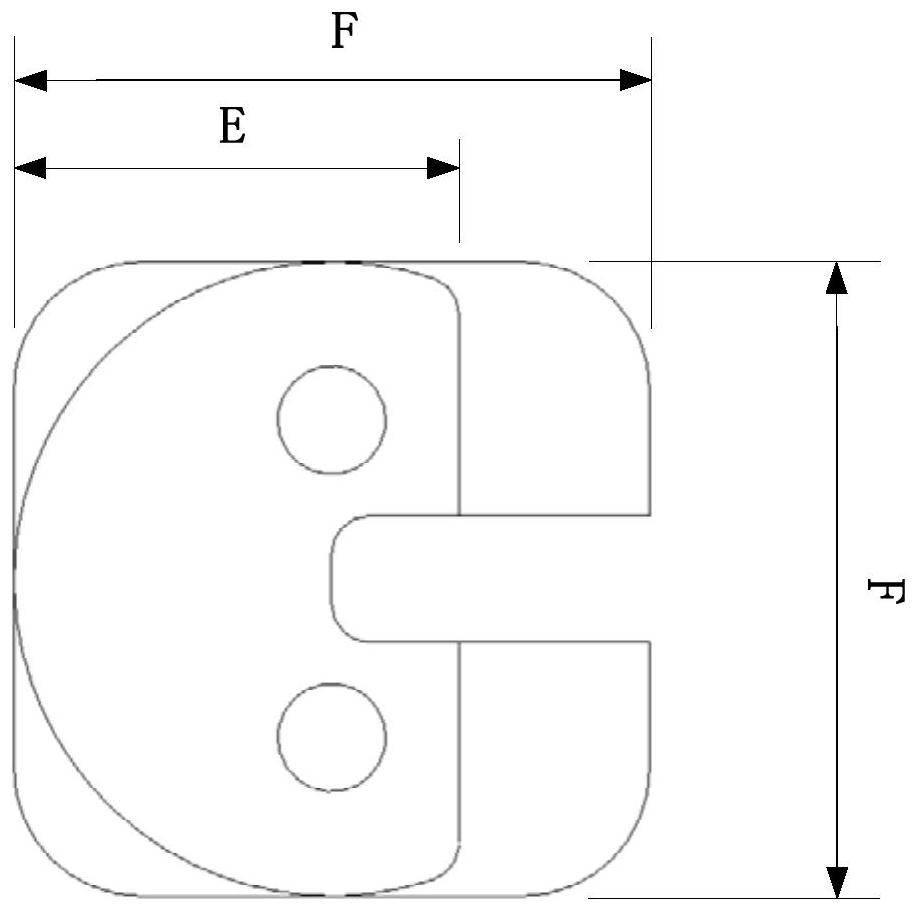

[0063] The center of the special-shaped spring 2 of the present invention is provided with an axial rectangular groove, and each of the two ends is respectively provided with a fan-shaped boss, followed by a left fan-shaped boss 10 and a right fan-shaped boss 11, and the axis of the fan-shaped boss coincides with the axis of the protection frame 4 . The special-shaped spring 2 is inserted into the protection frame 4 along the axial direction. A pair of fixed cover plates 1 are respectively arranged at the two ends of the protective frame 4, and the outer fan-shaped boss of the special-shaped spring 2 is inserted into the central through hole of the fixed cover plate 1 in turn, and the fixed cover plate 1 and the special-shaped cover plate 1 are connected by the fixed connecting bolts 3. The spring 2 and the protective frame 4 are fixed in position; among them, the protective frame 4, the special-shaped spring 2 and the fixed cover are filled with GF-5 polyurethane potting glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com