A bushing durability test device

A test device and durability technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of ineffective and timely evaluation of bushing durability, high cost of testing and processing, and long replacement cycle, etc. problem, to achieve the effect of reduced test cost, simple structure and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

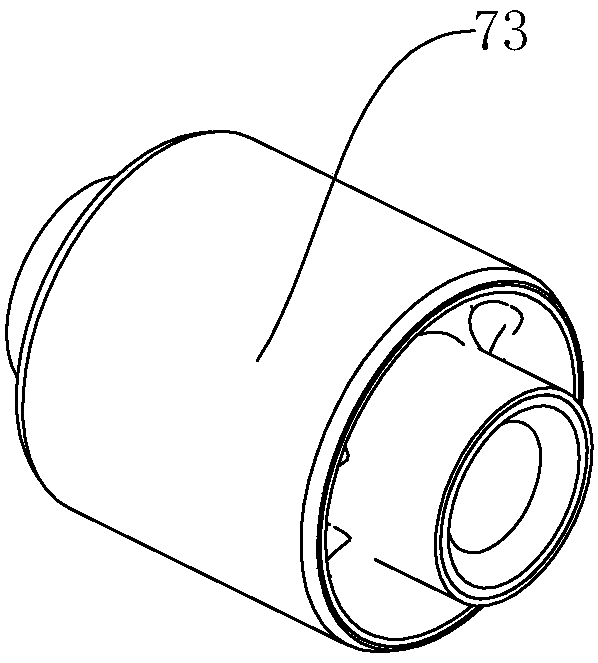

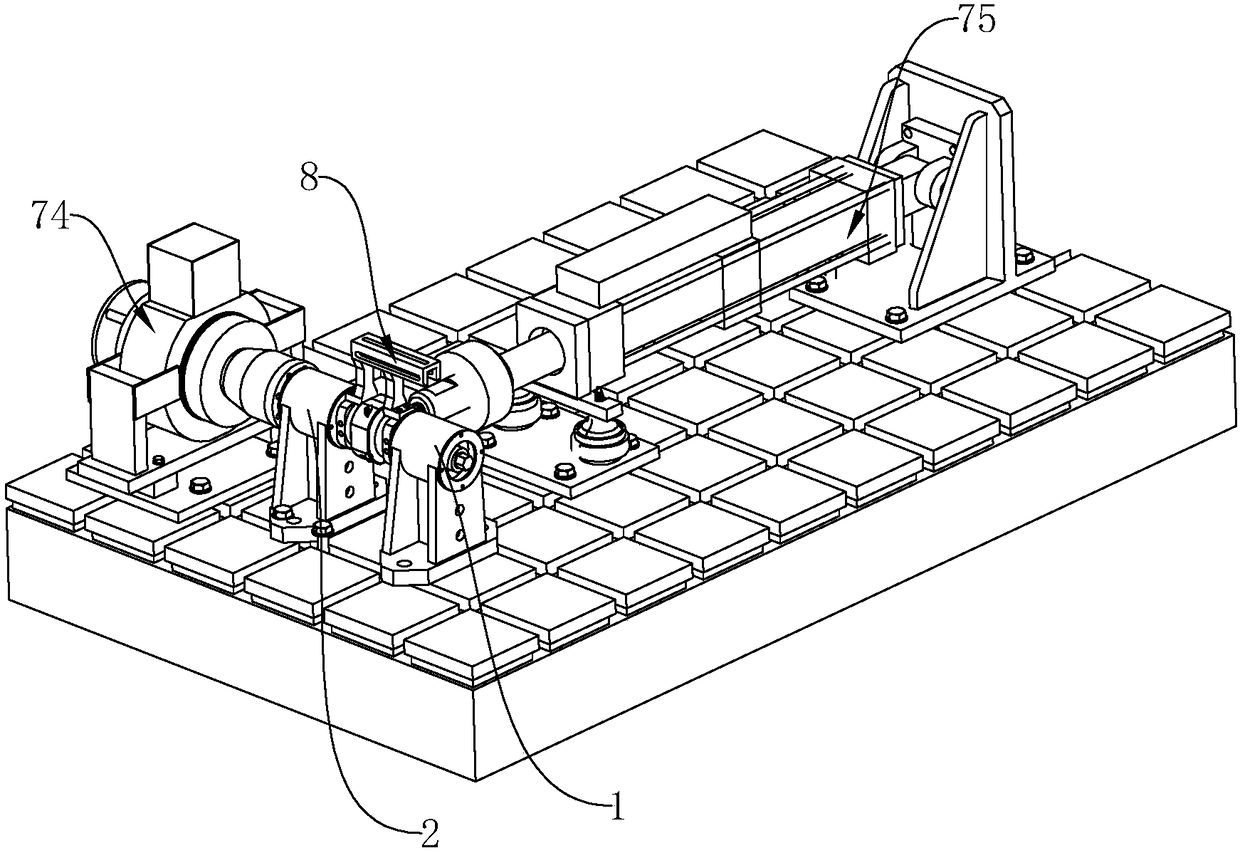

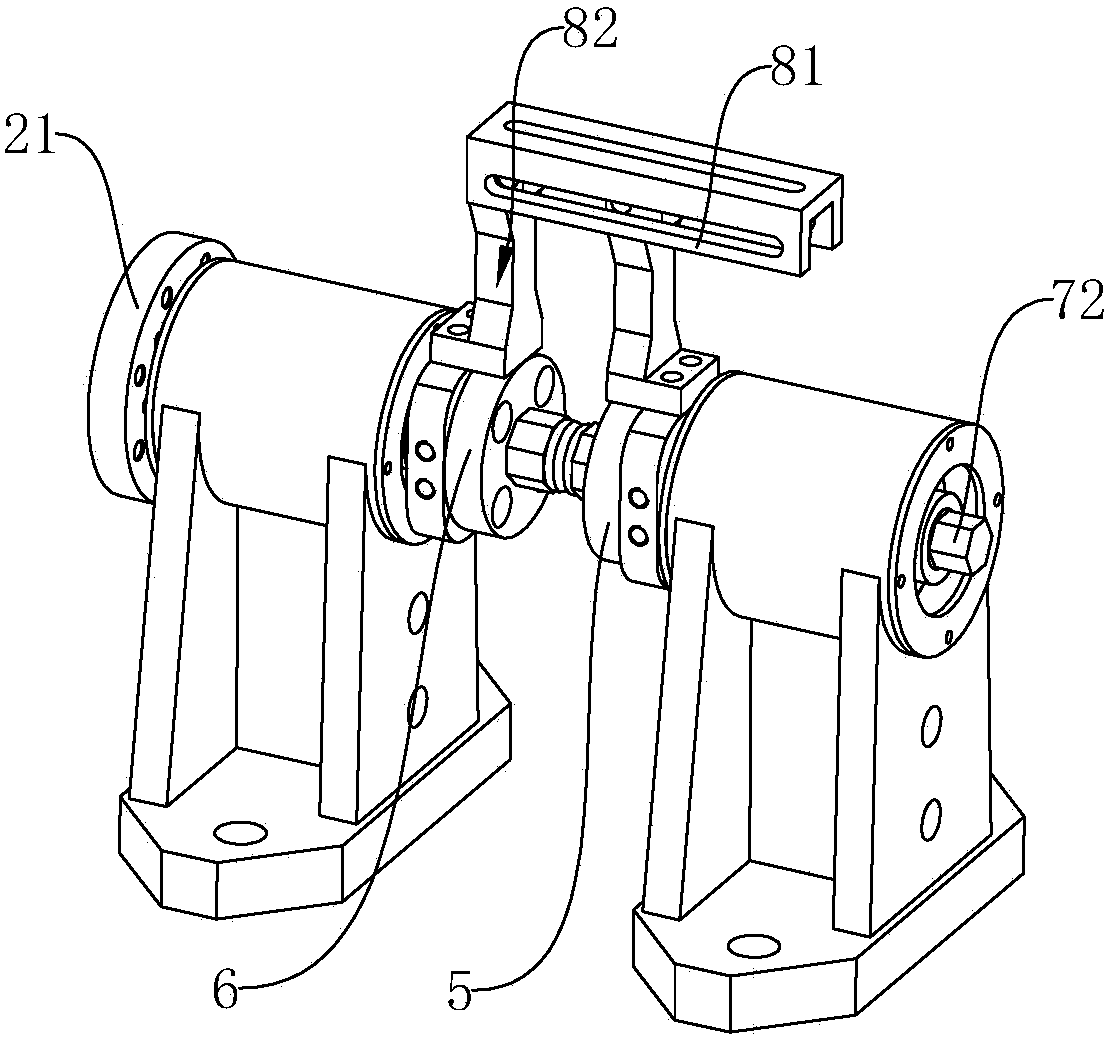

[0022] Embodiment 1: As shown in the figure, a bush durability test device includes a first support 1 and a second support 2, and the bush durability test device also includes a first connecting shaft 3 and a second connecting shaft 4 , the first flange 5, the second flange 6, the screw rod 71, the anti-loosening plug rod 72 and the balance mechanism 8, the first flange 5 and the second flange 6 are located on the first support 1 and the second Between the support 2, the first connecting shaft 3 is rotatably arranged on the first support 1, and the axial direction of the first connecting shaft 3 is provided with a first through hole 31 through which the left and right pass, and the second connecting shaft 4 is rotatably Set on the second support 2, the first flange 5 is fixedly connected with the first connecting shaft 3, the first flange 5 is provided with a second through hole 51 communicating with the first through hole 31, the second method The flange plate 6 is fixed on t...

Embodiment 2

[0026] Embodiment 2: The remaining parts are the same as in Embodiment 1, the difference is that a torsion disk 21 is provided on the outside of the second support 2, and the torsion disk 21 is fixedly connected to the second connecting shaft 4 in a detachable manner. The other part of the torsion disk 21 One end is fixedly connected with the torsion hydraulic cylinder 74, and the rotation angle of the torsion disc 21 is less than 180°.

[0027] The screw 71 is a high-strength screw 71 with a grade of 12.9.

[0028] The second flange 6 is provided with an internally threaded hole 61 coaxially disposed with the second through hole 51 and the diameter of the internally threaded hole 61 is equal to that of the second through hole 51 .

[0029] When testing bushes 73 of different specifications, the first flange 5 and the second flange 6 can be replaced so that the diameters of the second through hole 51 and the internal threaded hole 61 match the bushing 73, thereby realizing Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com