Automobile vacuum booster supporting plate fatigue testing device

A vacuum booster and fatigue test technology, which is applied in the testing of machines/structural components, measuring devices, testing of mechanical components, etc., can solve problems such as unfavorable research and development and production, shorten the fatigue verification cycle, simplify the structure of the device, and avoid time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

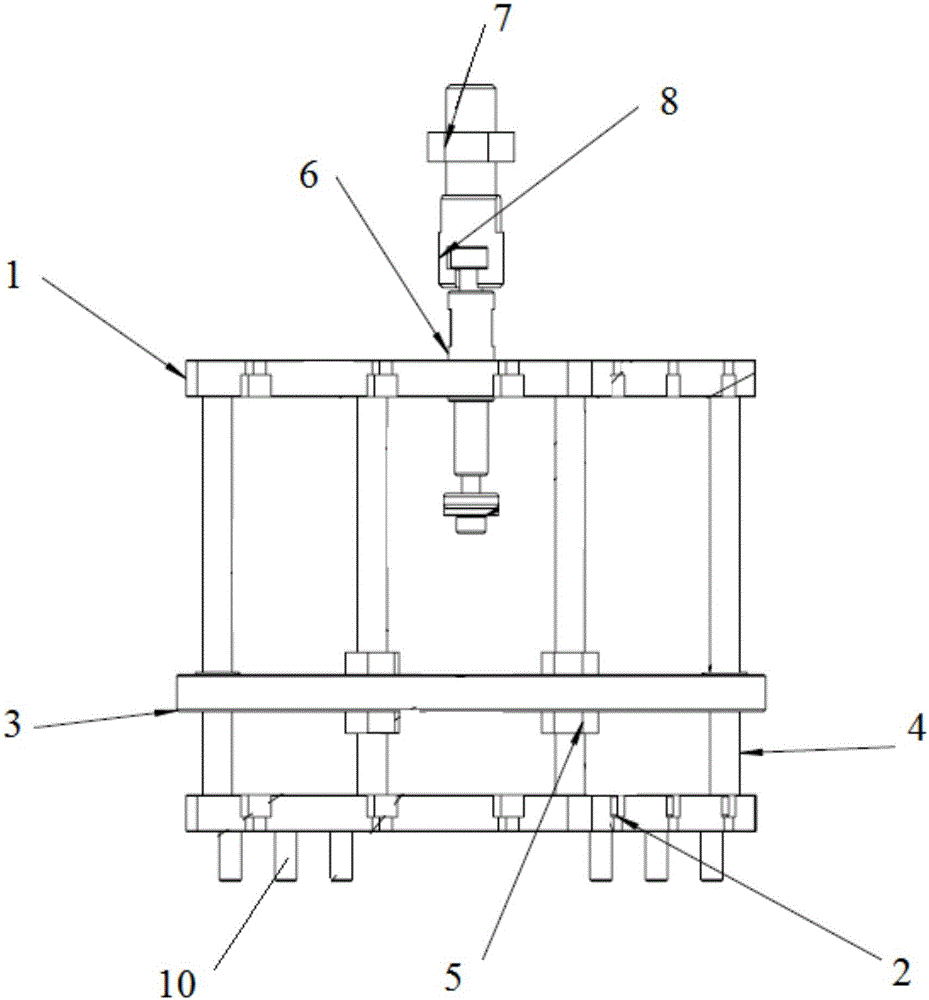

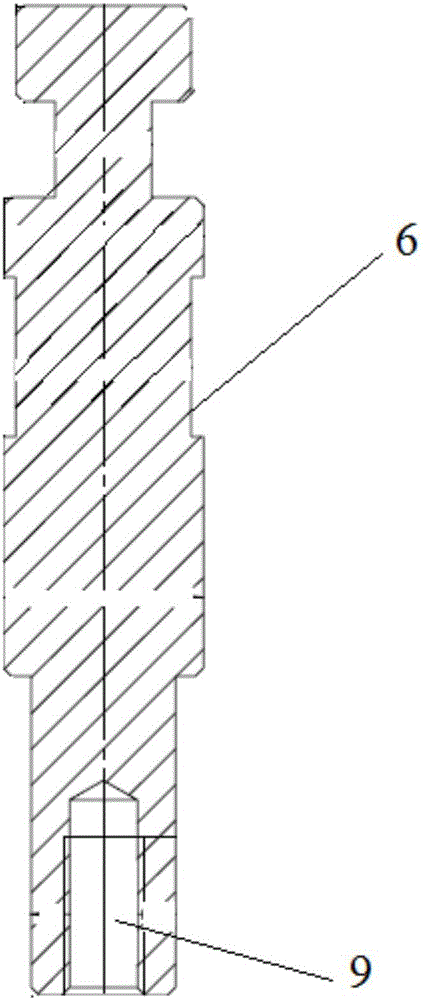

[0027] A fatigue test device for the pallet of an automobile vacuum booster, the structure of which is as follows: figure 1 with figure 2 As shown, it is used to carry out the supporting plate fatigue test with the tension and compression machine. The fatigue test device includes a fixed bracket, a fixed chassis 3 and a quick link structure. The fixed bracket includes an upper bracket 1, and is fixed to the tension and compression machine test The lower bracket 2 on the platform, the upper bracket 1 and the lower bracket 2 are all square frame structures, and there are four uniform guide rods 4 passing through the fixed chassis 3 between the upper bracket 1 and the lower bracket 2, so that the fixed The chassis 3 can move along the guide rods 4, and a fixed structure for clamping and fixing the chassis 3 is also provided on the two guide rods 4 that are diagonally distributed, and external threads are set on the guide rods 4 provided with the fixed structure, and the fixed st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com