An Evaluation and Prediction Method of Reliability Growth under Interval Censoring

A prediction method and reliability technology, applied in the direction of electrical testing/monitoring, testing/monitoring control systems, instruments, etc., to achieve the effect of making up for inconvenience, simple and reliable reliability evaluation method, and reducing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0102] The implementation case verifies the effectiveness of the invention in combination with the shutdown data of a pipeline compressor auxiliary system.

[0103] From 2012 to 2014, a pipeline compressor auxiliary system had a total of 91 outage records. The specific data are shown in the following table:

[0104] Table 1 Failure and downtime of pipeline compressor auxiliary system from 2012 to 2014

[0105]

[0106]

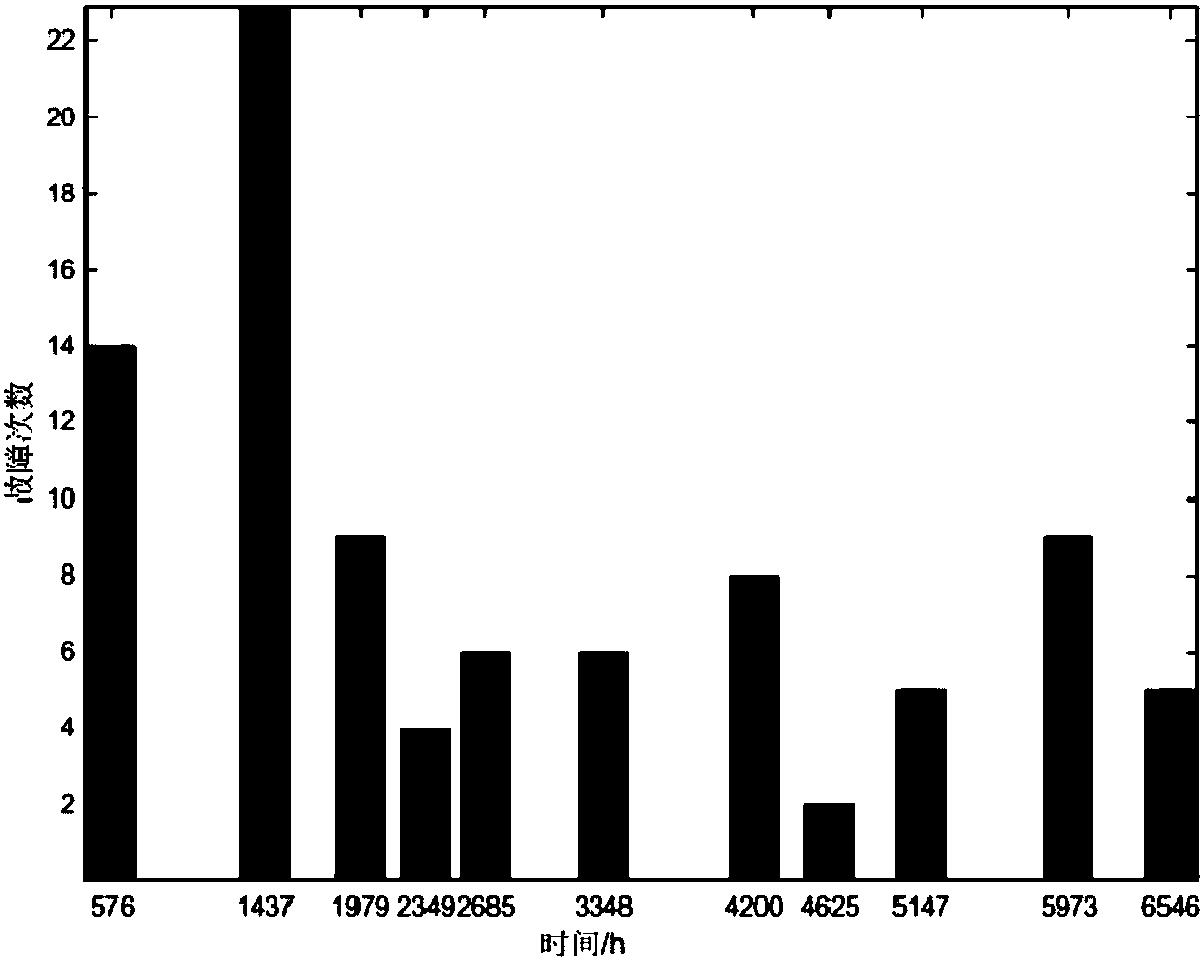

[0107] figure 1 It is a statistical histogram of the number of downtimes of the auxiliary system of the pipeline compressor, from which it can be found that the number of failures of the auxiliary system of the compressor has a trend of decreasing fluctuations.

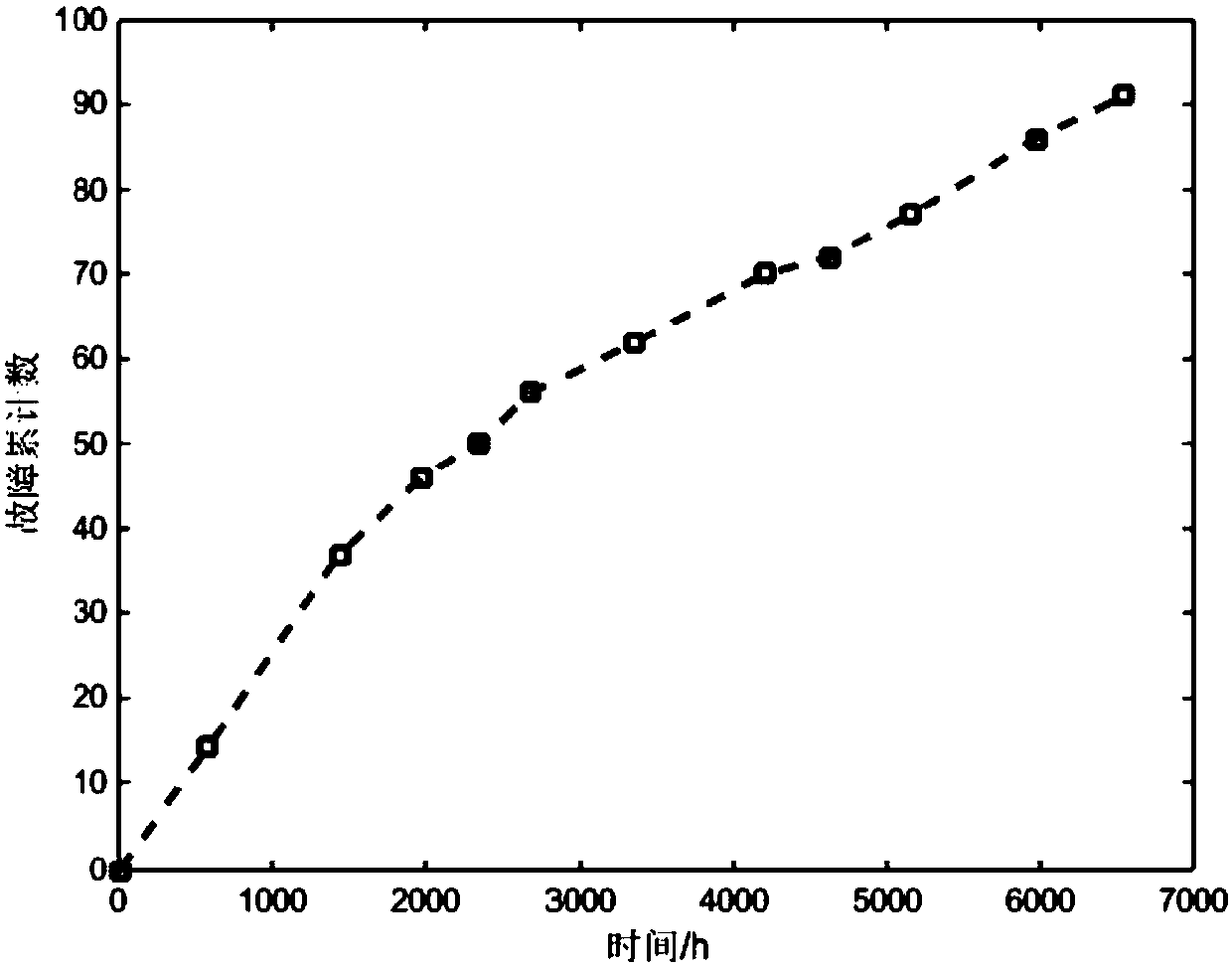

[0108] figure 2 It is the cumulative number of failures of the auxiliary system of the pipeline compressor - the cumulative test time graph. The curve is convex upward. At this time, the interval between adjacent failures increases and the product reliability increases.

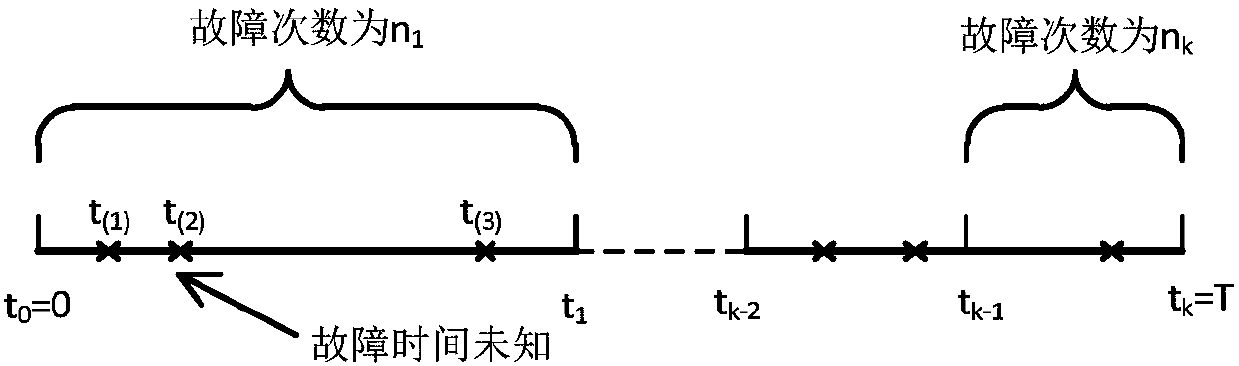

[0109] image 3is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com