Preheating cable skinning knife

A stripping knife, cable technology, applied in cable installation, cable installation device, equipment for dismantling/armored cables, etc., can solve the problems of low work efficiency, easy cable damage, poor safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

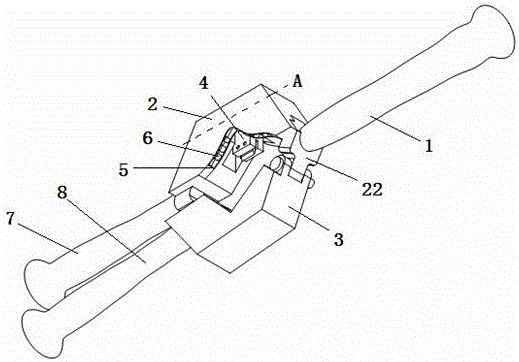

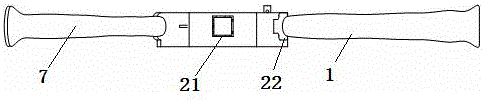

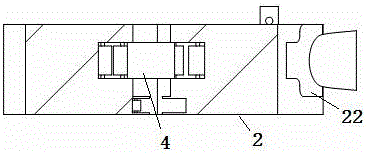

[0020] For the preheating type cable stripping knife of this embodiment, refer to the attached Figure 1-4 , including fixed handle 1, upper sipe 2 and lower sipe 3. Wherein, the outer side of the upper sipe 2 and the lower sipe 3 is U-shaped, and the inner side is a V-shaped groove. The upper sipe 2 and the lower sipe 3 are respectively inverted U-shaped and positive U-shaped. Put it into the circular area formed by the fastening of the V-groove on the inner side of the upper and lower sipes.

[0021] The lower part of the U-shaped end of the upper sipe 2 is connected to the U-shaped end of the lower sipe 3 through the movable part 22. The upper and lower handles are movably connected by long bolts, and the upper and lower handles use long bolts as shafts to realize the opening and closing of the upper and lower sipes, and the fixed handle 1 is fixed on the outside of the movable part 22 at the same time.

[0022] The other ends of the U shape of the upper slit 2 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com